Redox active polyhydroquinone microspheres and preparation method thereof

A polyhydroquinone and microsphere technology, applied in the field of functional materials, can solve the problems of unstable product performance, difficult processing, insoluble and infusible, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

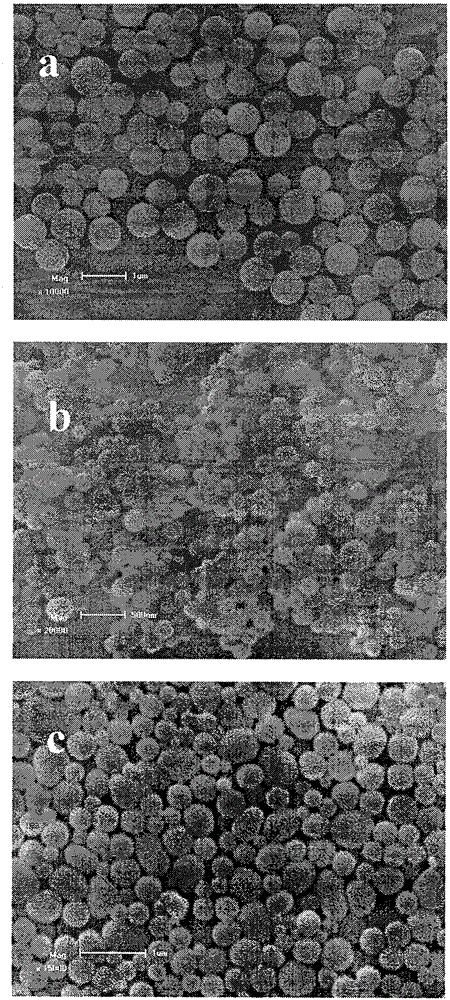

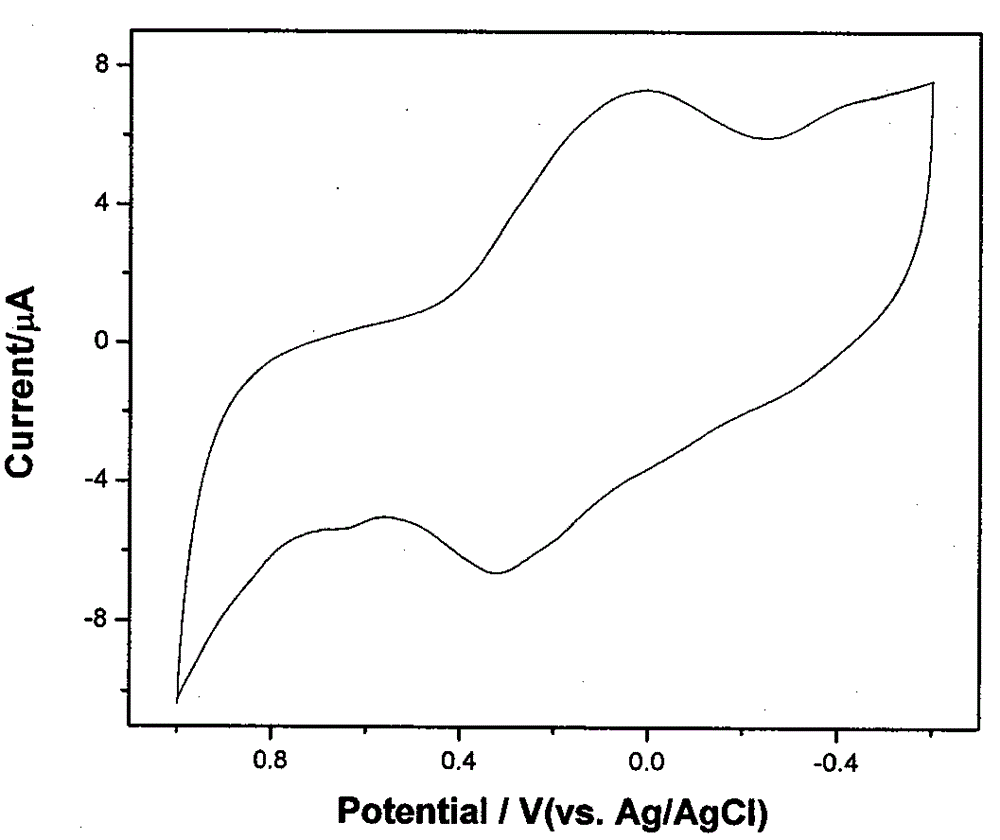

[0017] Add 1.65g of hydroquinone, 15.0mL of 4.4% PEG1000 aqueous solution and 125.6mL of water into the reaction flask, mix well and add 6.0mL of 0.02% ferrous sulfate aqueous solution and 3.4mL of hydrogen peroxide; After reacting for 24 hours, a black polymer microsphere dispersion was obtained, and the microspheres were separated by centrifugation, and dried in vacuum at 50° C. for 24 hours. The obtained polyhydroquinone microspheres had a particle diameter of 1020 nm. Taking silver / silver chloride as a reference electrode, the reduction peak potential of the microsphere dimethyl sulfoxide dispersion casting film is 0.12 volts, and the oxidation peak potential is 0.34 volts.

Embodiment 2

[0019] Add 1.65g of hydroquinone, 15.0mL of 4.4% PEG1000 aqueous solution and 128.6mL of water into the reaction flask, mix well and add 3.0mL of 0.02% ferrous sulfate aqueous solution and 3.4mL of hydrogen peroxide; After reacting for 24 hours, a black polymer microsphere dispersion was obtained, and the microspheres were separated by centrifugation, and dried in vacuum at 50° C. for 24 hours. The obtained polyhydroquinone microspheres had a particle diameter of 860 nm. Taking silver / silver chloride as a reference electrode, the reduction peak potential of the microsphere dimethyl sulfoxide dispersion casting film is 0.21 volts, and the oxidation peak potential is 0.57 volts.

Embodiment 3

[0021] Add 1.65g of hydroquinone, 30.0mL of 4.4% PEG1000 aqueous solution and 110.6mL of water into the reaction flask, mix well and add 6.0mL of 0.02% ferrous sulfate aqueous solution and 3.4mL of hydrogen peroxide; After reacting for 24 hours, a black polymer microsphere dispersion was obtained, and the microspheres were separated by centrifugation, and dried in vacuum at 50° C. for 24 hours. The obtained polyhydroquinone microspheres had a particle diameter of 680 nm. Taking silver / silver chloride as a reference electrode, the reduction peak potential of the microsphere dimethyl sulfoxide dispersion casting film is 0.10 volts, and the oxidation peak potential is 0.32 volts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com