Preparation method of furnace bottom roller graphite carbon sleeve impregnating solution

A technology of dipping liquid and graphite carbon, which is applied to the preparation of impregnating liquid for furnace bottom roller graphite carbon sleeves and the field of impregnation treatment of graphite carbon sleeves, can solve problems such as intractability, achieve the effects of convenient operation, reduce corrosion and facilitate industrial implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Take by weighing in the following ratio: 25wt% sodium tripolyphosphate, 25wt% sodium hexametapolyphosphate, 15wt% B 2 o 3 , 10wt% SiO 2 , 10wt% ZrO 2 , 10wt%TiO 2 , 4.5wt% MgO, 0.25wt% cerium nitrate, 0.25wt% gadolinium nitrate, mixed ball mill for 2 hours; the mixed powder was dissolved in 70°C water, wherein the total mass of the powder accounted for 5wt% of the total mass of the liquid, and stirred for 10 minutes; 0.5 wt% of the total mass of the mixed powder is weighed out of carboxymethyl cellulose, mixed into the above liquid, and stirred for 20 minutes until the liquid is clear to form an impregnating liquid.

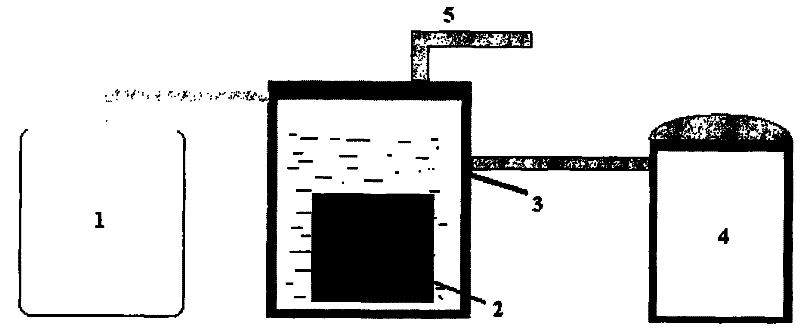

[0016] Heat the graphite product 2 to 300°C, immerse it in the impregnating device 3 filled with the impregnating liquid while it is hot, adjust the temperature of the impregnating device 3 to 100°C, and the pressure to 0.6MPa, impregnate for 24 hours, take it out and dry it naturally.

Embodiment 2

[0018] Take by weighing in the following ratio: 20wt% sodium pyrophosphate, 30wt% sodium hexametapolyphosphate, 15wt% B 2 o 3 , 10wt% Al 2 o 3 , 10wt% ZrO 2 , 10wt%TiO 2 , 4.5wt% MgO, 0.5wt% lanthanum chloride, mixed ball mill for 2 hours; the mixed powder was dissolved in 80°C water, wherein the total mass of the powder accounted for 6wt% of the total mass of the liquid, and stirred for 10 minutes; 1 wt% starch by mass is mixed into the above liquid, and stirred for 20 minutes until the liquid is clear to form a dipping liquid.

[0019] Heat the graphite product 2 to 400°C, immerse it in the impregnating device 3 filled with the impregnating liquid while it is still hot, adjust the temperature of the impregnating device 3 to 95°C, and the pressure to 0.5 MPa, immerse it for 20 hours, take it out and dry it naturally.

Embodiment 3

[0021] Weigh according to the following ratio: 35wt% sodium tripolyphosphate, 20wt% potassium tetrapolyphosphate, 10wt% B 2 o 3 , 10wt% SiO 2 , 10wt% ZrO 2 , 10wt%TiO 2 , 4.5wt% NiO, 0.5wt% cerium oxide, mixed and ball milled for 2 hours; the mixed powder was dissolved in water at 80°C, wherein the total mass of the powder accounted for 8wt% of the total mass of the liquid, and stirred for 10 minutes; according to the total mass of the mixed powder 0.5wt% of the citric acid was weighed, mixed into the liquid, and stirred for 20 minutes until the liquid became clear to form an impregnating liquid.

[0022] Heat the graphite product 2 to 500°C, immerse it in the impregnating device 3 filled with impregnating liquid while it is still hot, adjust the temperature of the impregnating device 3 to 105°C, and the pressure to 0.4MPa, immerse for 30 hours, take it out and dry it naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com