Method for producing H2O2 with Pa catalytic agent in working solution containing three solvents

A technology of H2O2 and working fluid, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low hydrogenation efficiency and low viscosity, and achieve the effect of reducing freight costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

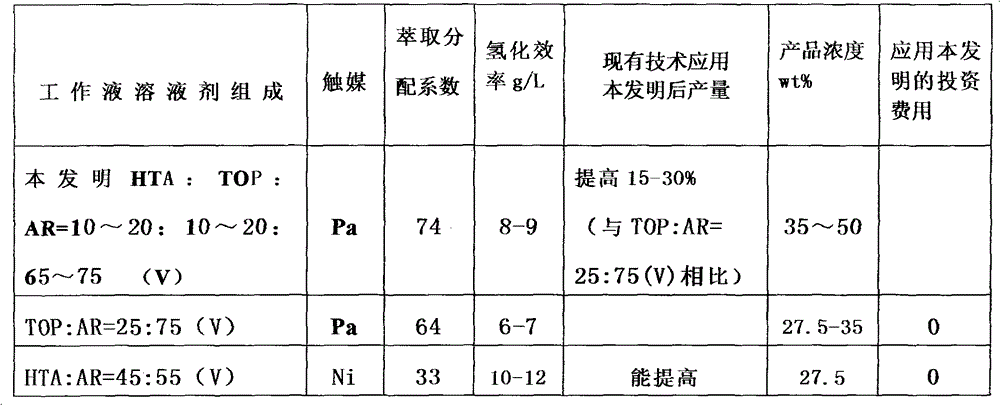

[0015] A Pa catalyst produces H under the working solution composed of three-component solvents 2 o 2 According to the method, the Pa catalyst is added to the fixed-bed reactor, protected with nitrogen, and then the working solution composed of HTA, TOP, AR, according to the volume ratio of HTA, TOP, AR is 10~20:10~20:65~ 75 is added in the described reactor, and the volume sum of HTA, TOP, AR is 100. The hydrogen gas with a purity of 98-99.8% is introduced from the bottom of the reactor, and the hydrogenation reaction is carried out at 60-80 ° C. The hydrogen gas from the top of the reactor is recycled through the hydrogen circulation compressor, and hydrogenated at 8g / L-9g / L The liquid comes out from the bottom of the reactor and is cooled to 40-50°C, and the N is separated under reduced pressure. 2 、CH 4 After waiting for the gas mixture, the hydrogenated liquid enters the tower from the top of the oxidation tower through a pump, and undergoes an oxidation reaction with ...

Embodiment 2

[0019] HTA: TOP: The working solution of AR=14: 16: 70 (V) composition, carries out by embodiment 1 operating steps and method, and its hydrogenation efficiency is 8.4g / l, H 2 o 2 The yield is 20% higher than TOP:AR=25:75 (V), and the product concentration is 50wt%.

Embodiment 3

[0021] HTA: TOP: AR=11: 19: 70 (V) The working solution of composition, carries out by embodiment 1 operating steps and method, and its hydrogenation efficiency is 8.0g / l, H 2 o 2 The yield is 15% higher than TOP:AR=25:75 (V), and the product concentration is 35wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com