Method and device for removing sulfur and carbon oxides from power plant flue gas in combination mode

A combined removal and oxidation technology, applied in the field of flue gas purification, can solve the problems of evaporation water consumption, complex flue gas coexisting components, waste of ash field resources, etc., and achieve the effects of reducing costs, good application prospects, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

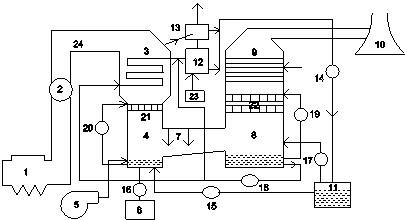

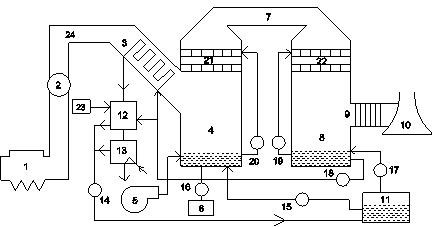

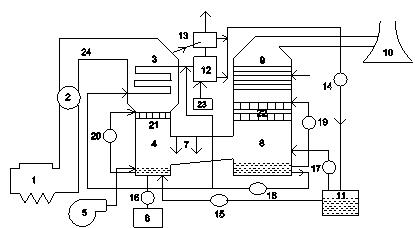

[0021] The method of the present invention uses ammonia water as an absorbent to integrally remove sulfur and carbon oxides in the flue gas of a power plant. After carbonization, the inlet temperature of the flue gas is 100-180°C, and the inlet temperature of the solution after decarburization is 20-30°C. After decarburization, the solution is preheated to 70-80°C and then enters the desorption tower for steam heating and analysis. After decarburization, the solution (the main component is ammonium bicarbonate) decomposes, ammonia and CO2 are separated, and a small part of the volatile and escaped ammonia gas and The analyzed CO2 enters the condenser together to remove escaped ammonia, and the separated CO2 is to be stored or converted for utilization. The ammonia water condensed by the condenser and the ammonia water resolved by the desorption tower are returned to the ammonia water storage tank in the removal process for recycling. The low-temperature flue gas cooled by hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com