Pressure-driven lift seedling culture bed

A seedling bed, lifting technology, applied in the field of seedlings, can solve the problems of mutual interpenetration of seedling roots, unfavorable seedling rooting, increased seedling cost, etc., and achieve the effect of fast response, convenient design and application, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

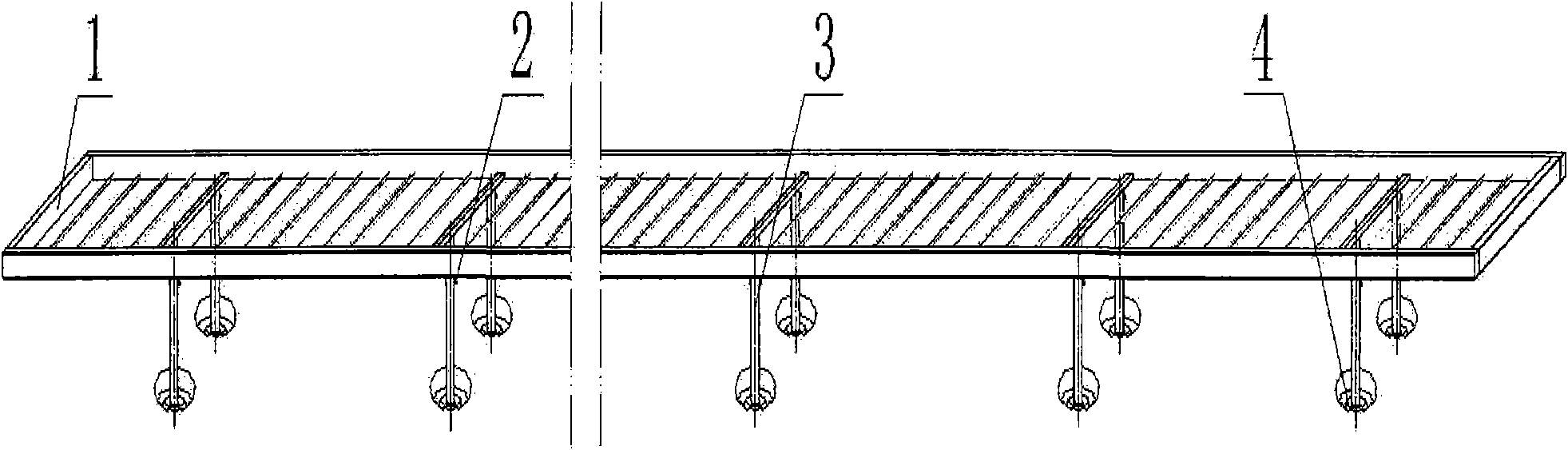

[0030] The pressure lifting type seedling bed structure includes a seedling bed frame 1, a lifter 4 and a pressure system, and its structure is connected as follows:

[0031] 1. The seedling bed frame of the seedling bed 1

[0032] according to image 3 The seedling raising bed frame 1 of seedling raising bed is made up of bed frame outer frame 14, seedling tray support bar 15, bed frame bar 16 and connecting tube 17; Bar 16 and seedling tray support bar 15 are welded, and bed frame horizontal bar 16 is provided with connecting tube 17 below, and seedling raising bed frame 1 is provided with one deck.

[0033] 2. The lifter 4 of the nursery bed

[0034] according to Figure 4The lifter 4 of nursery bed is made up of cylinder barrel 24, piston 19, piston connecting rod 3, horizontal positioning sleeve 20, buffer spring 21, cylinder cover 22 and cylinder cover fixing bolt 25. Cylinder 24 materials are PVC pipes, and the pressure is 1Mpa. The lower end of cylinder 24 uses pip...

Embodiment 2

[0038] The pressure lifting type seedling bed structure includes a seedling bed frame 1, a lifter 4 and a pressure system, and its structure is connected:

[0039] 1. Seedling bed frame for seedbed 1

[0040] according to image 3 The seedling raising bed frame 1 of seedling raising bed is made up of bed frame outer frame 14, seedling tray support bar 15, bed frame bar 16 and connecting tube 17; Bar 16 and seedling tray support bar 15 are welded, and bed frame horizontal bar 16 is provided with connecting tube 17 below, and seedling raising bed frame 1 is provided with two layers.

[0041] 2. The lifter 4 of the nursery bed

[0042] according to Figure 4 The lifter 4 of nursery bed is made up of cylinder barrel 24, piston 19, piston connecting rod 3, horizontal positioning sleeve 20, buffer spring 21, cylinder cover 22 and cylinder cover fixing bolt 25. Cylinder 24 materials are PVC pipes, and the pressure is 1Mpa. The lower end of cylinder 24 uses pipes and accessories t...

Embodiment 3

[0045] Embodiment 3: Applied to cultivating light matrix eucalyptus tissue culture seedlings

[0046] Adopt the pressure lifting type seedling bed of embodiment 1, utilize the water supply system of existing water pressure 0.45-0.5MPa of nursery as pressure source, transplant the eucalyptus tissue culture seedling that has resumed growth in the nursery greenhouse, move to net room pressure lifting type When continuing to cultivate on the bed frame of the nursery bed, at first, in order to help the seedlings retain water and fertilizer, and promote the growth of the seedlings, the seedbed is required to be lowered from the high position to the lowest position. The inlet valve 8 should be closed, the outlet valve 11 should be opened, and under the reaction force of the buffer spring 21 and the self-weight of the seedling bed frame 1, the piston connecting rod 3 and the piston 19 should be moved downward to discharge the pressure water, and the seedling bed frame 1 would drop to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com