Circuit board resin film evener and using method thereof

A circuit board and leveling machine technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of inability to bond resin layers, circuit board deformation, and large amount of resin, so as to achieve convenient installation and disassembly, and improve production efficiency. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

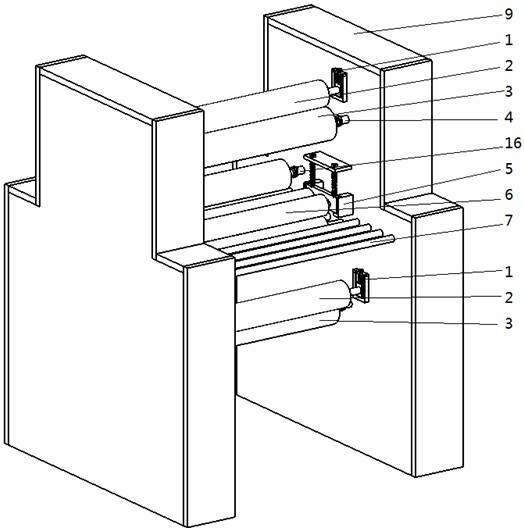

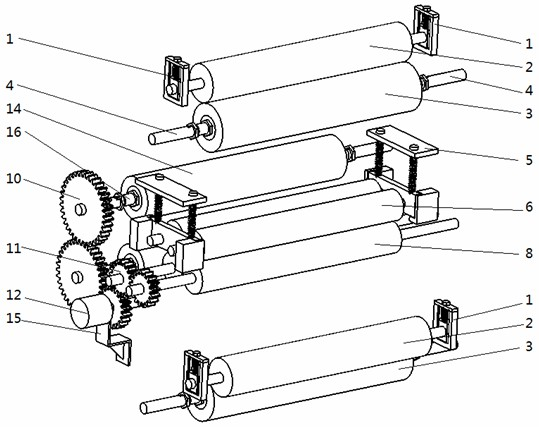

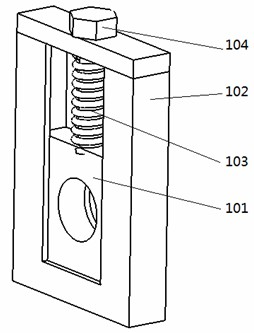

[0023] Such as Figure 1~5 As shown, a circuit board resin lamination leveling machine includes a film feeding mechanism, a film collecting mechanism, a flattening mechanism, a material guide mechanism, a transmission mechanism and a frame 9; the film feeding mechanism includes an upper film feeding mechanism and a lower film feeding mechanism , the upper film feeding mechanism and the lower film feeding mechanism include a pressing end 1, a pressing roller 2, a film feeding roller 3 and a film feeding buckle fixing frame 4; the film receiving mechanism includes an upper film receiving mechanism and a lower film receiving mechanism, The upper film-winding mechanism and the lower film-winding mechanism include a film-winding roller 14, a film-winding buckle fixing frame 16 and a film-winding gear 10; the flattening mechanism includes an upper flattening roller 6, a lower flattening roller 8, and an elastic fixing frame 5 and flattening gear 11; material guide mechanism includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com