Quick-change drill chuck

A drill chuck and chuck technology, applied in the field of tools, can solve problems such as inconvenient and awkward operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

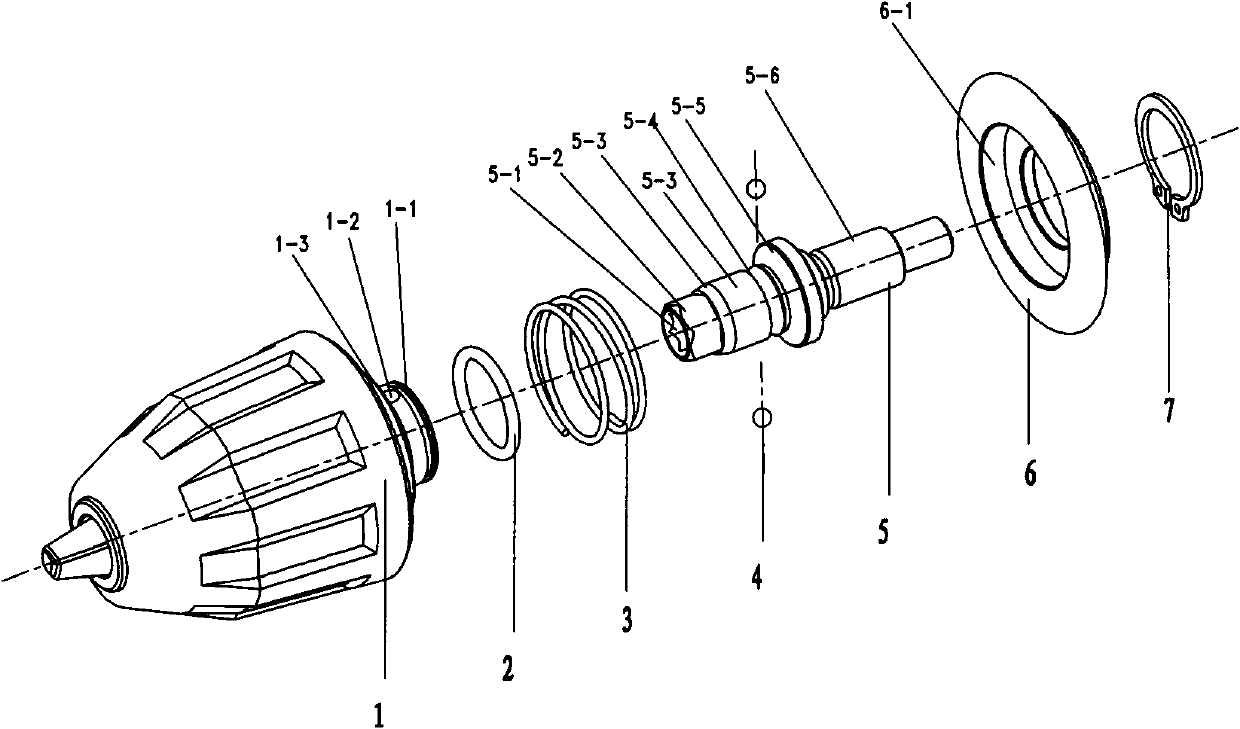

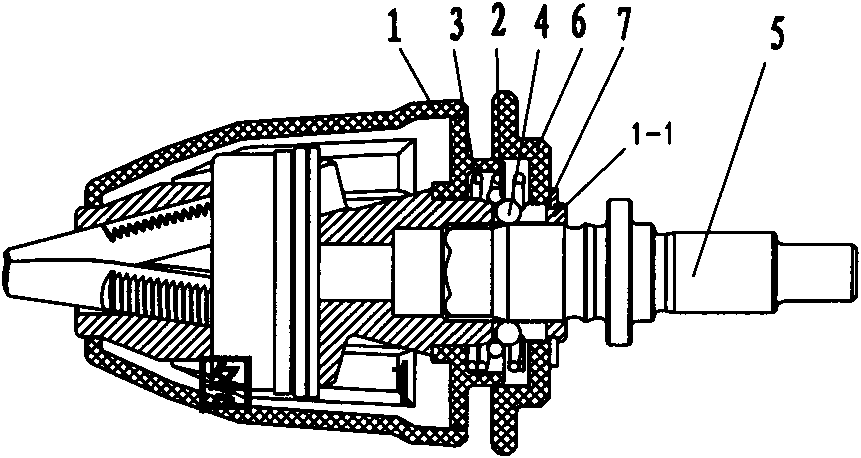

[0022] The quick-change drill chuck of the present embodiment is as figure 1 As shown, it is mainly composed of a collet body 1 that can form a circumferential constraint with the output shaft, a compression spring 3 , an unlocking ring 6 and an electric drill output shaft 5 . The middle part of the rear end surface of the chuck body 1 extends out of the sleeve 1-1 and the outer ring 1-3 whose inner hole is in clearance fit with the output shaft 5. Parts—the axially extending long perforations 1-2 of the steel ball 4. The outer end of the sleeve pipe 1-1 is equipped with a circlip 7 for the shaft.

[0023] The end of the output shaft 5 has an inner hexagonal screwdriver socket 5-1, the front part has an outer hexagonal non-circular section 5-2 that can form a circumferential constraint with the corresponding structure of the casing, and the middle cylindrical section has a 5-3 The annular groove 5-4 that steel ball matches. The outer hexagonal non-circular section 5-2 conne...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that the radial elastic member adopts Figure 7The effect of the split elastic ring shown is similar to that of the ring spring in Embodiment 1, and can be deduced by analogy. Other structures are the same as those in Embodiment 1, and will not be repeated here.

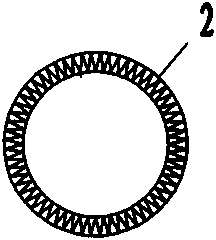

[0030] In addition to the annular spring and the split elastic ring, the above radial elastic members can also adopt other variable structures, such as a ring structure with internal teeth, and the ring has elastic inner teeth inclined towards the axial direction. When the blade is elastically deformed in the axial direction by the axial force, the inner diameter of the envelope formed by the tooth top of the inner gear blade will also expand elastically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com