Flat plug

A plug and plug body technology, applied to electrical components, coupling devices, circuits, etc., can solve the problems of easy to block socket jacks, inconvenient to pull the pry board, and large pry board area, so as to reduce costs and save labor , space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

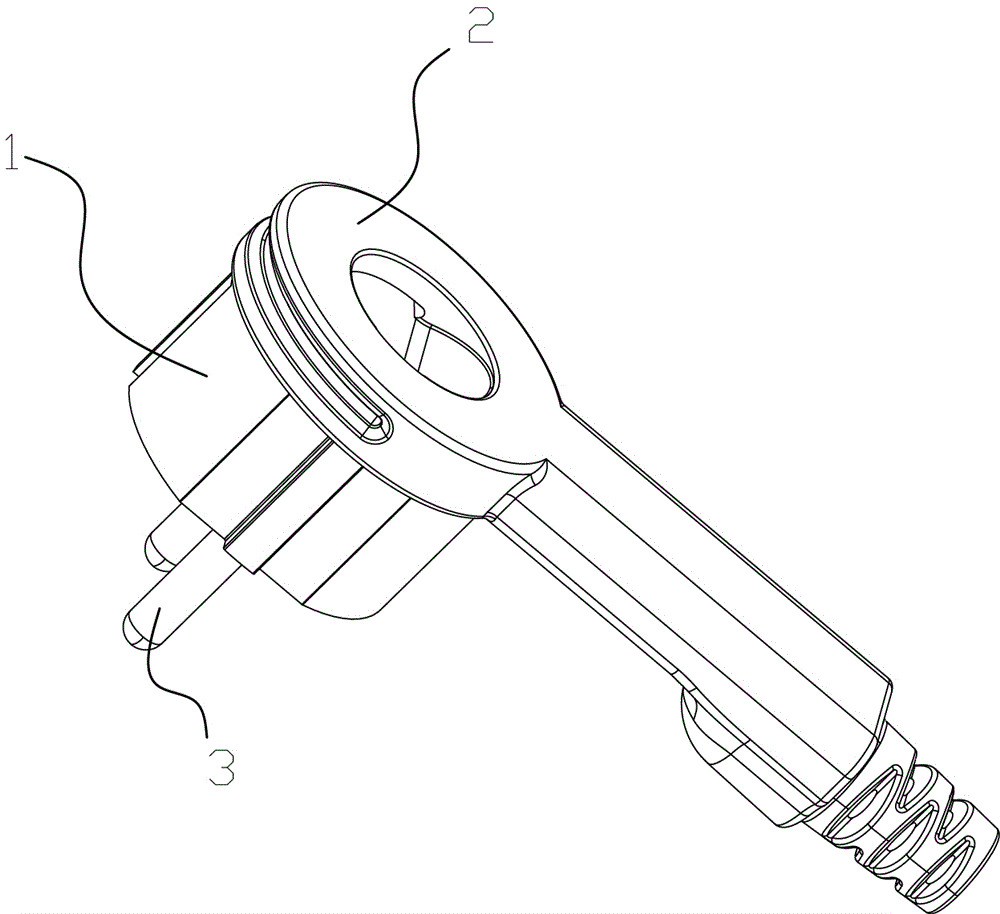

[0014] Such as figure 1 As shown, a flat plug includes a plug body 1, a conductive pin 3 is provided on one side of the body 1, and a side of the body 1 opposite to the side where the conductive pin 3 is provided A drawing part 2 is provided on it, a part of the drawing part 2 is integrated with the body 1, and the area of the part connected to the body 1 on the drawing part 2 accounts for 1 / 2 of its total area, so The drawing part is ring-shaped and made of silica gel material, and is integrated with the plug body by encapsulation, and there is a gap between the drawing part 2 and the side of the body where it is located. When the plug is pulled out, the pulling part 2 can be folded to a position perpendicular to the side where it is located.

[0015] When pulling out the plug, first turn over the puller 2 to make it stand u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com