Driving motor for vehicle

A technology for driving motors and vehicles. It is applied in the direction of electrical components, electromechanical devices, and electric components. It can solve the problems of good sealing, affecting the precision of the motor, and troublesome replacement, and achieves the effect of reliable fixing and convenient disassembly and assembly of Hall elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

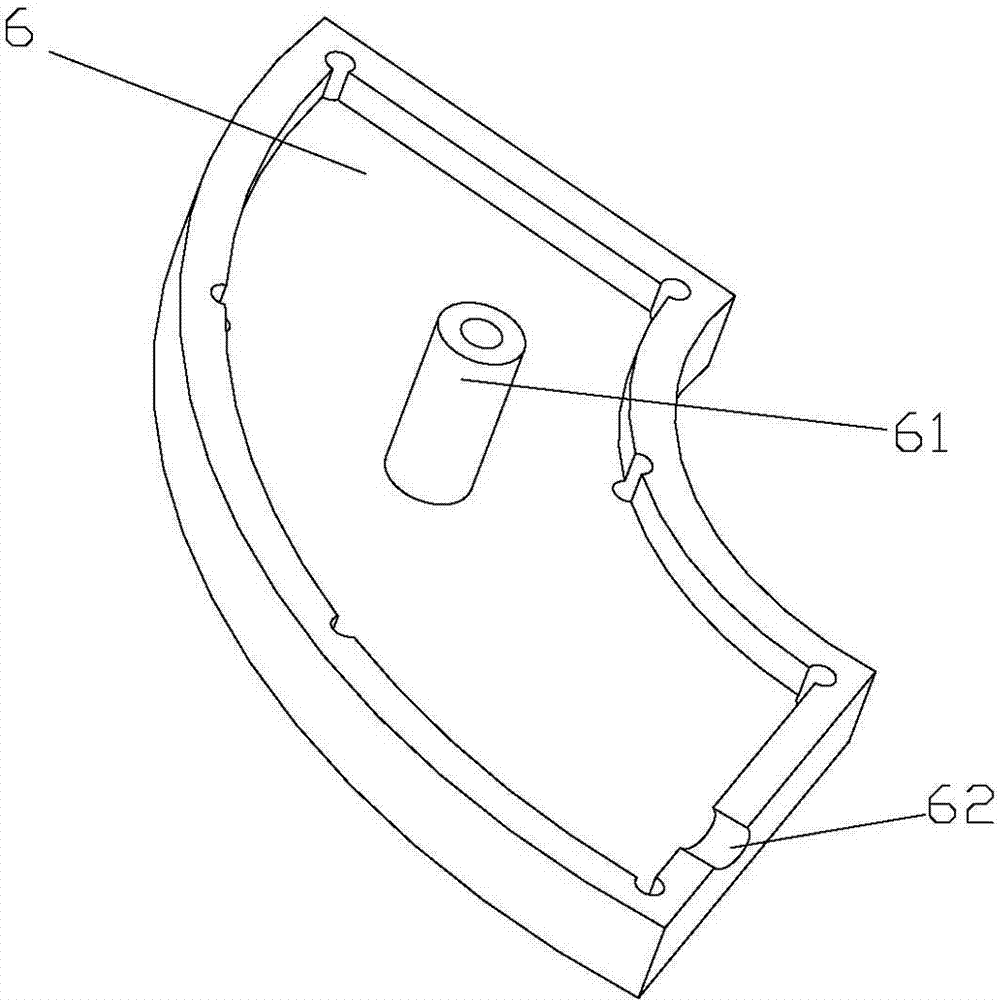

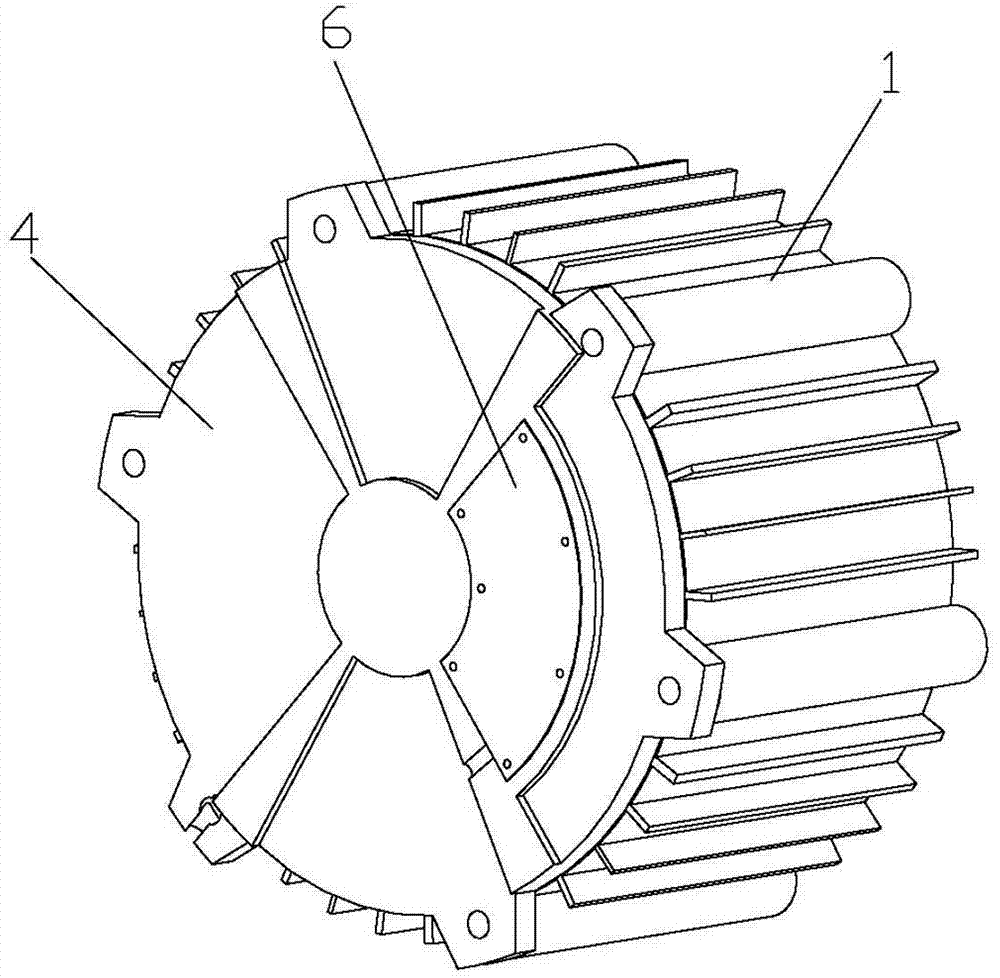

[0013] Such as Figure 1-4 As shown, a driving motor for a vehicle includes a housing 1, a stator 2, a rotor 3 and an end cover 4. The stator 2 and the rotor 3 are housed in the housing 1 and arranged coaxially. The Hall element 5, the Hall element 5 is provided with a pin 51, and the rear end of the iron core of the stator 2 corresponding to it is provided with a jack 21, and the Hall element 5 is inserted into the jack 21 through the pin 51 Fixed, there is a gap 41 at the position corresponding to the end cover 4 and the Hall element 5, a sealing cover 6 is provided at the gap 41, and a push rod or a top tube 61 is also provided on the inside of the sealing cover 6, when When the sealing cover 6 is fastened to the sealed notch 41, the ejector rod or the ejector tube 61 can withstand the Hall element 5; a line hole 62 is opened at the edge of the notch 41 and the sealing cover 6 for the control line of the Hall element 5 to pass through .

[0014] The Hall element of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com