Metal plate bending machine

A metal plate and bending machine technology, applied in the field of metal plate processing, can solve the problems of large bending angle, poor bending angle accuracy, and increased cost, and achieve the effect of large bending angle range, small size, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be further described in detail below.

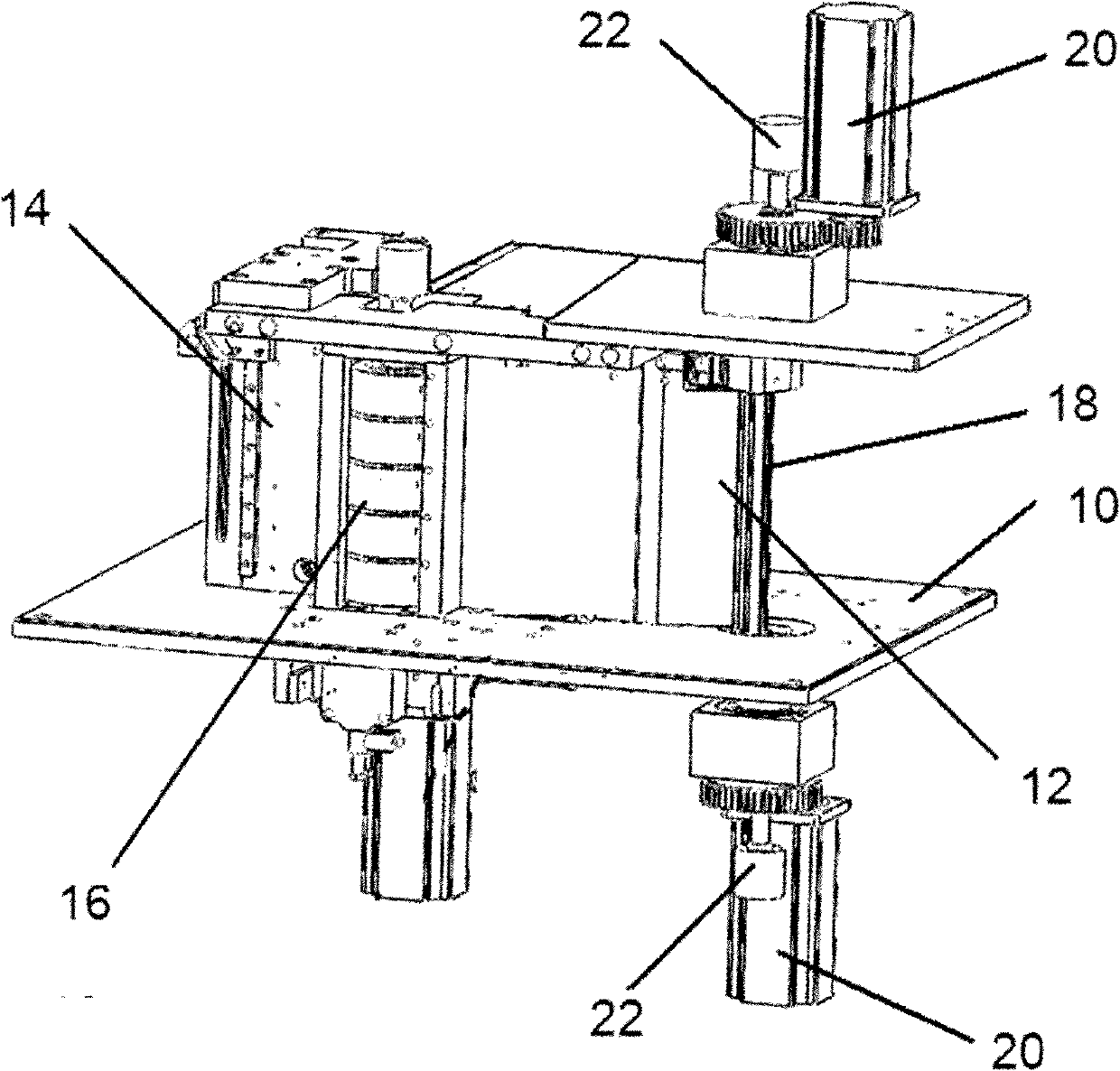

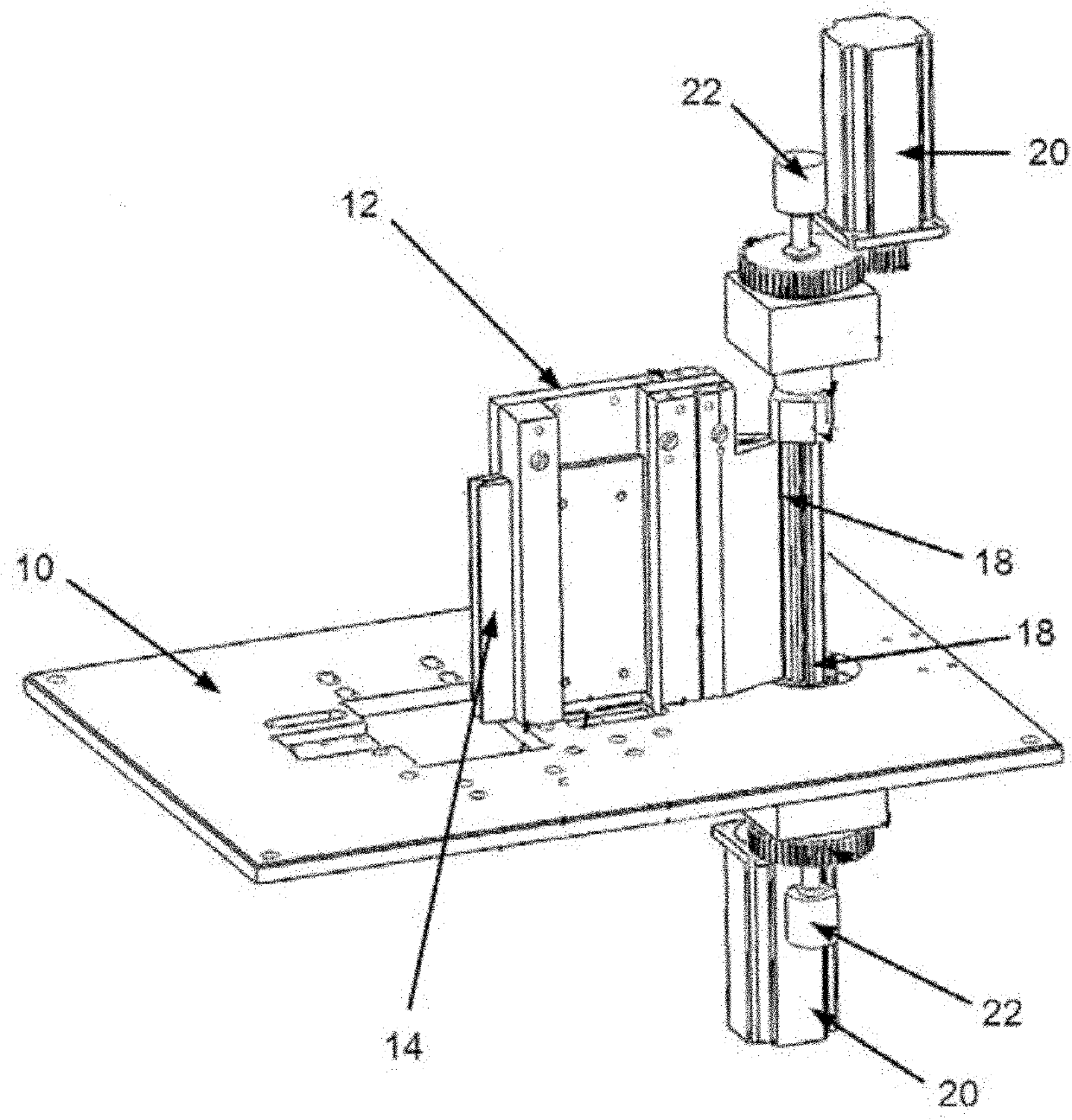

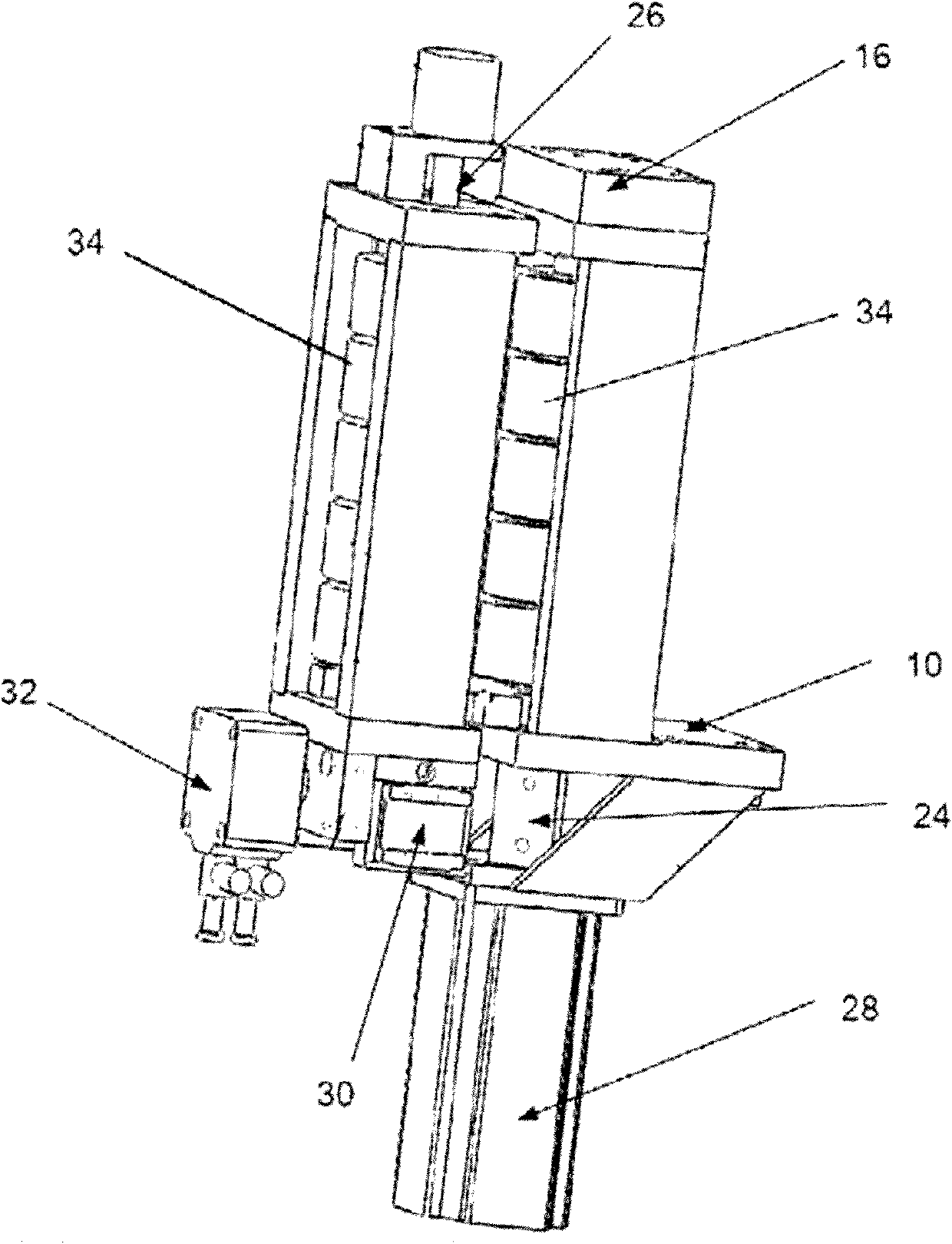

[0022] Such as figure 1 with figure 2 As shown, the metal plate bending machine of the present invention includes an operation table 10, on which two side plates 12 are vertically arranged, and the two side plates 12 are parallel to each other and have a certain distance. The channel between the two side plates 12 is the material channel for the metal plate to pass therethrough. A guiding device 14 is provided before the entrance of the material channel, a clamping device 16 for clamping the metal plate is provided in the middle of the material channel, and elongated bending knives 18 are provided on both sides of the outlet of the material channel. The bending knives 18 are all perpendicular to the operating table 10 . Two first motors 20 are arranged on the console 10 , driven by the first motors 20 , the bending knife 18 can rotate horizontally around its vertical central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com