Separator for nonaqueous secondary battery

A secondary battery, non-aqueous technology, applied in the direction of secondary batteries, battery components, separators/films/membranes/spacers, etc., can solve the problem of insufficient ion permeability, and the porous structure has not been disclosed in detail and other problems, to achieve the effect of excellent heat resistance and ion permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

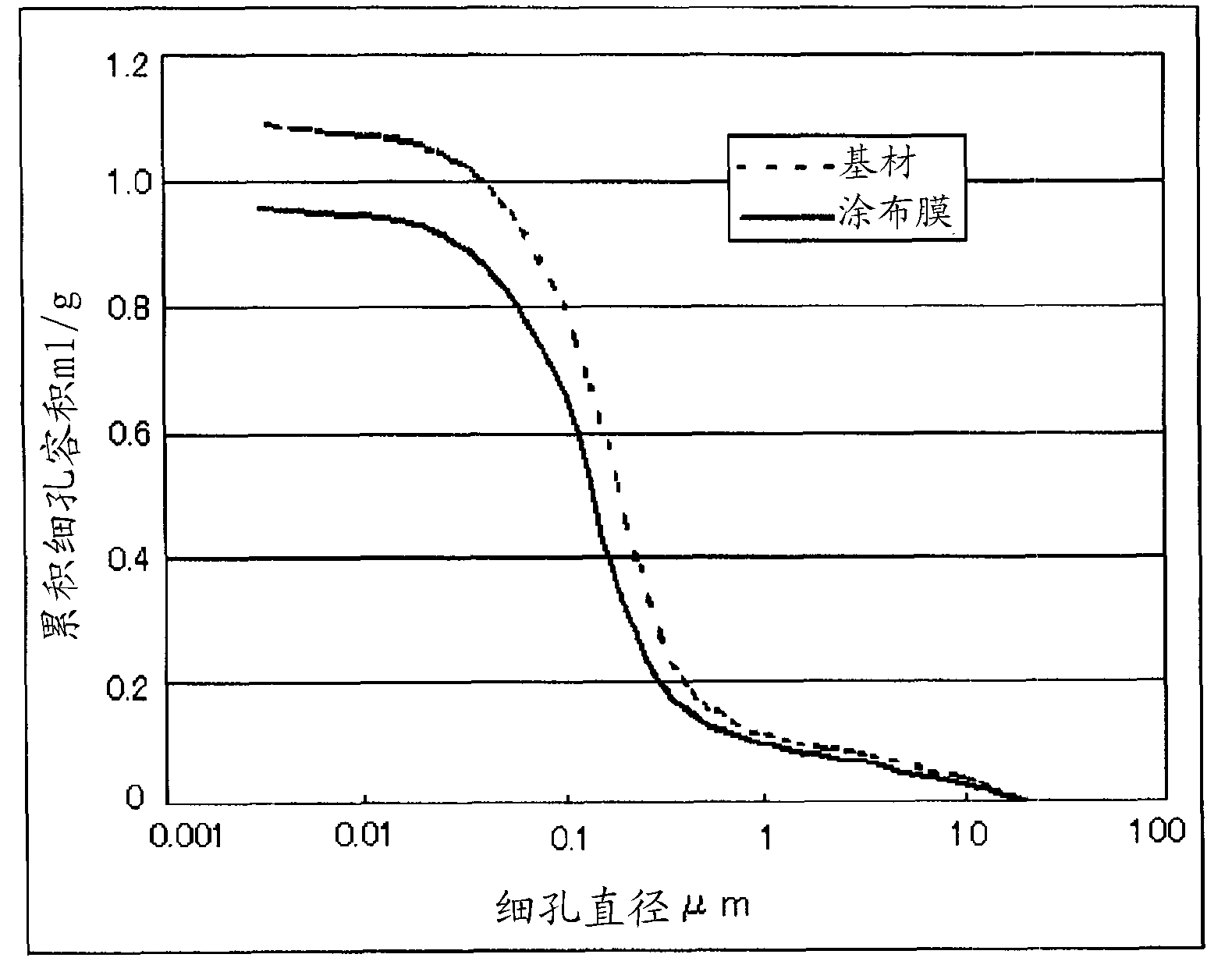

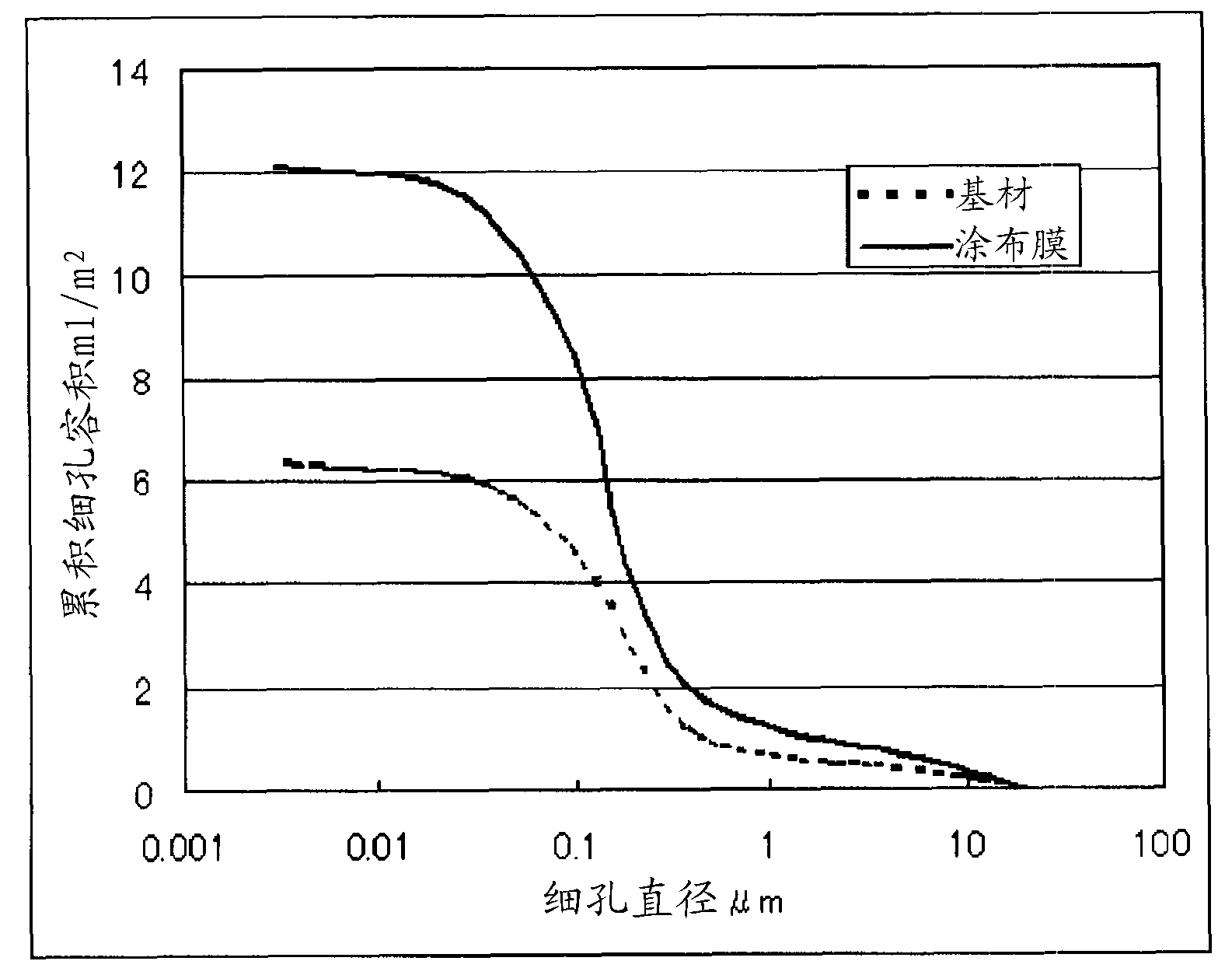

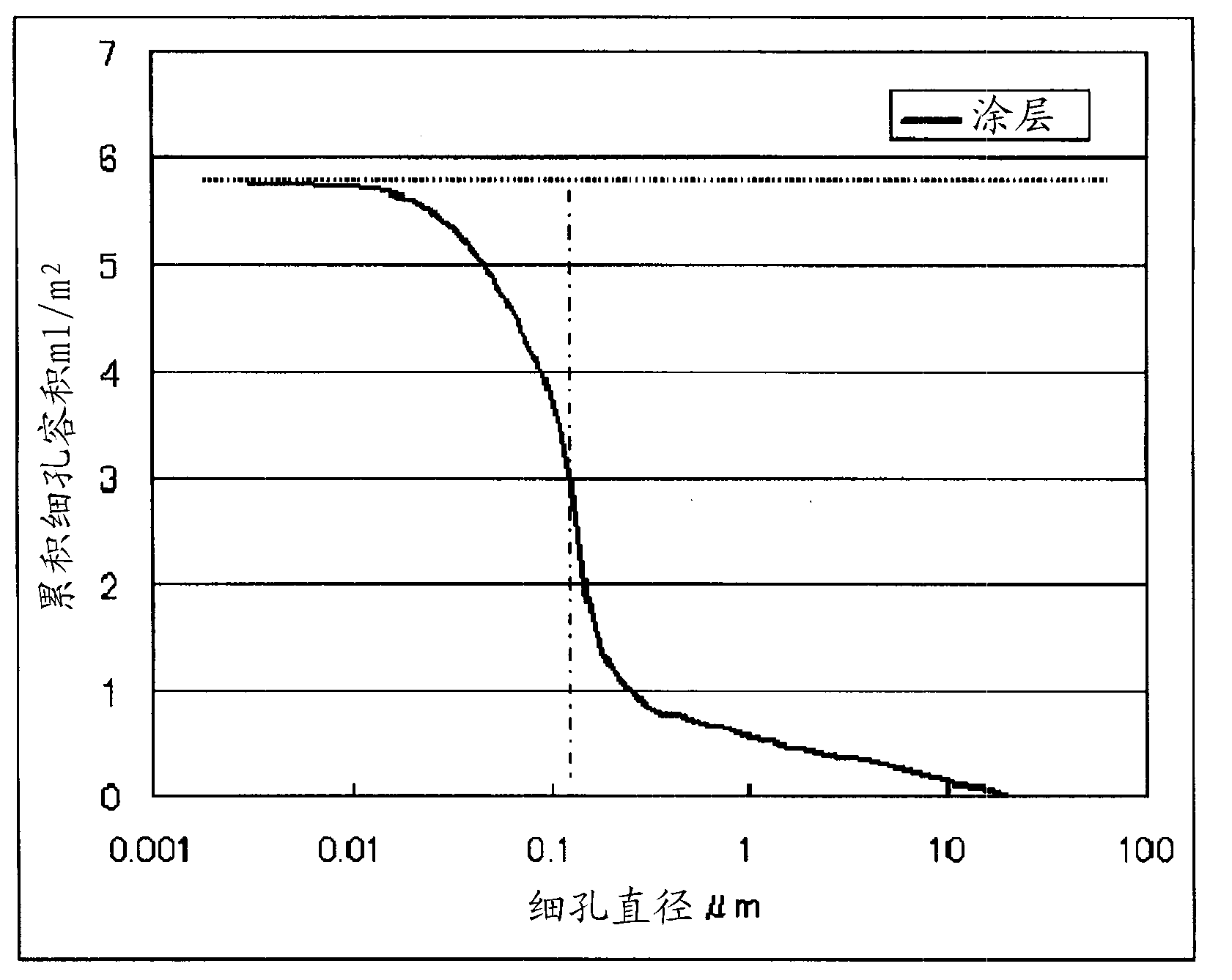

[0244] As the polyethylene powder, GUR2126 (weight average molecular weight: 4.15 million, melting point: 141°C) and GURX143 (weight average molecular weight: 560,000, melting point: 135°C) manufactured by Ticona Corporation were used. The ratio of GUR2126 and GURX143 was 1:9 (weight ratio), and they were dissolved in a mixed solvent of liquid paraffin (manufactured by Matsumura Petroleum Research Institute; Sumoil P-350P; boiling point 480°C) and decahydronaphthalene to make poly The ethylene concentration was 30% by weight to prepare a polyethylene solution. The composition of the polyethylene solution is polyethylene: liquid paraffin: decahydronaphthalene=30:45:25 (weight ratio). This polyethylene solution was extruded from a die at 148° C., cooled in a water bath, and a gel-like tape (tape base) was produced. The base tape was dried at 60° C. for 8 minutes and at 95° C. for 15 minutes, and the base tape was stretched biaxially by longitudinal stretching and transverse str...

Embodiment 1-2

[0248] As the polyethylene powder, GUR2126 (weight average molecular weight: 4.15 million, melting point: 141°C) and GURX143 (weight average molecular weight: 560,000, melting point: 135°C) manufactured by Ticona Corporation were used. The ratio of GUR2126 and GURX143 was 2:8 (weight ratio), and they were dissolved in a mixed solvent of liquid paraffin (manufactured by Matsumura Petroleum Research Institute; Sumoil P-350P; boiling point 480°C) and decahydronaphthalene to make polyethylene The concentration was 30% by weight to prepare a polyethylene solution. The composition of the polyethylene solution is polyethylene: liquid paraffin: decahydronaphthalene=30:68:2 (weight ratio). This polyethylene solution was extruded from a die at 148° C., cooled in a water bath, and a gel-like tape (tape base) was produced. The base tape was dried at 60° C. for 8 minutes and at 95° C. for 15 minutes, and the base tape was stretched biaxially by longitudinal stretching and transverse stret...

Embodiment 1-3

[0251] A separator for a non-aqueous secondary battery of the present invention was obtained in the same manner as in Example 1-1 except that magnesium hydroxide (manufactured by Kyowa Chemical Industry Co., Ltd.; Kisuma 5P) having an average particle diameter of 0.8 μm was used as the inorganic filler. In this separator, the coating amount of the heat-resistant porous layer was 5.05 g / m on both sides. 2 , the porosity of the heat-resistant porous layer was 66%. The entire separator had a film thickness of 20 μm, a porosity of 54%, and a piercing strength of 351 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com