Specialty paper containing regenerated plant protein fiber for filling filter rod of cigarette

A vegetable protein, cigarette filter rod technology, applied in special paper, paper, papermaking and other directions, can solve the problem of not considering paper degradation, inconvenience in the length of acetate fiber, the impact of paper quality, etc. The effect of improving paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

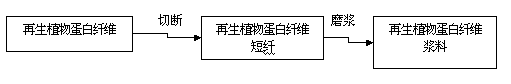

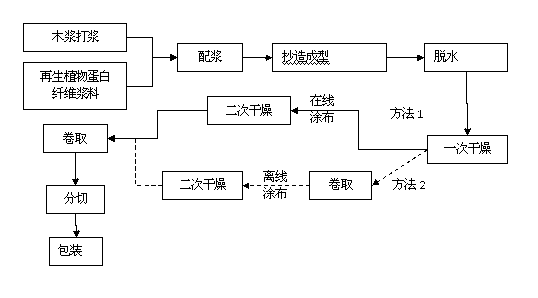

[0021] The regenerated vegetable protein fiber such as corn protein fiber such as figure 1 Cut to 0.8mm as shown and refine again to obtain the regenerated vegetable protein fiber slurry, then mix it with the coniferous wood pulp fiber of 23 ° SR according to coniferous wood pulp fiber: regenerated vegetable protein fiber = 40:60 in the pulping tank uniform slurry, according to figure 2 As shown, use a paper machine to make a shape. After dehydration and primary drying, the functional additive polychitosan solution is coated on the paper surface according to 1% of the dry paper weight, and then dried for the second time to obtain a quantitative value of 35g / m2, special paper containing regenerated vegetable protein fibers with a thickness of 0.15mm, and then coiled, cut, and packaged to obtain the finished product.

Embodiment 2

[0023] Soy protein fiber such as figure 1 Shown cut to 0.5mm and then refining, to obtain regenerated vegetable protein fiber slurry, then with softwood pulp fiber, hardwood pulp fiber prepared respectively according to softwood pulp fiber: hardwood pulp fiber: regenerated vegetable protein fiber = 13:17:70 Mix the slurry evenly in the mixing tank, press figure 2 As shown, use a paper machine to make a shape. After dehydration and primary drying, the Zimbabwean tobacco leaf extract solution is coated on the paper surface by 5% of the dry paper weight, and then dried for the second time. Special paper with a thickness of 0.1mm containing regenerated vegetable protein fibers, then coiled, cut and packaged.

Embodiment 3

[0025] Papermaking is 60g / m2, thickness is the specialty paper that contains regenerated plant protein fiber of 0.32mm, and each material ratio is coniferous wood fiber: hardwood pulp fiber: regenerated plant protein fiber=30:10:60. Wherein the treatment of regenerated vegetable protein fiber pulp is as follows: figure 1 As shown, the regenerated plant protein fiber is first cut to 2.0mm ~ 5.0mm for pulping, and the regenerated plant protein fiber slurry and the coniferous wood pulp slurry of 38 ° SR are mixed evenly in the pulping tank, and press figure 2 The process shown is papermaking, dehydration, coiling after drying once, and then coating with the extract of tobacco produced in Honghe, Yunnan in off-line mode, and the coating application amount is 10% of the dry paper weight. After secondary drying, coiling, cutting and packaging are carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com