X80 steel grade anti-corrosion low-temperature seamless line pipe

A seamless line pipe, anti-corrosion technology, applied in the field of seamless steel pipe manufacturing, to achieve the effect of saving usage, saving investment and reducing consumption of welding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

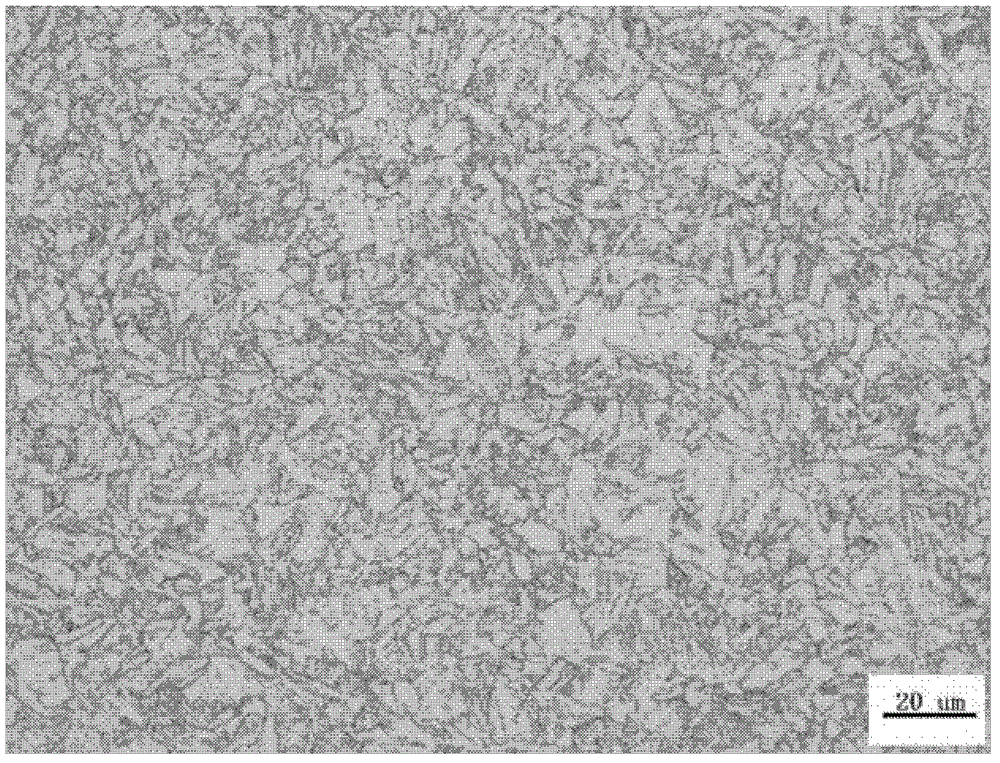

[0012] The X80 steel grade corrosion-resistant low-temperature seamless line pipe of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0013] In the X80 steel grade anti-corrosion low-temperature seamless line pipe of the present invention, the reasons for selecting the main components are analyzed as follows:

[0014] Carbon: The most economical and basic strengthening element in steel, it has a significant effect on improving the strength of steel through solid solution strengthening and precipitation strengthening, and has the advantages of low cost and good control sensitivity. However, high content also has the disadvantage of negatively affecting the weldability, mechanical properties and HIC (hydrogen-induced cracking) resistance of steel. In addition, the strength matching relationship between carbon and steel is also particularly important, because the level of carbon content is directly proportional to the streng...

PUM

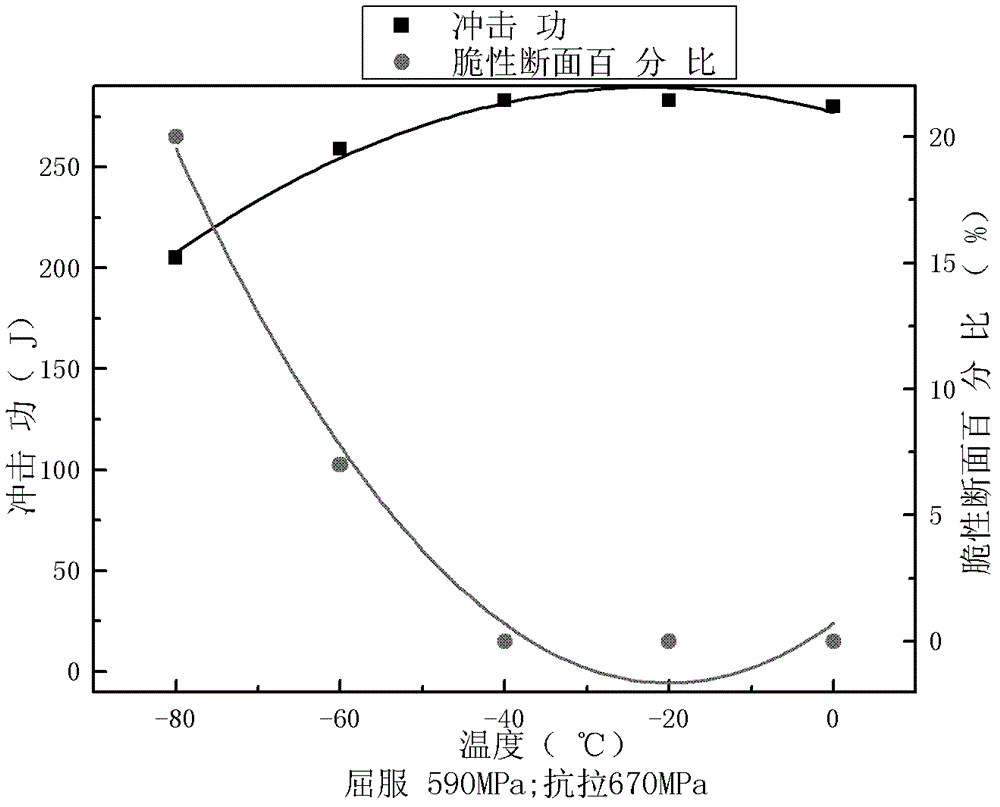

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com