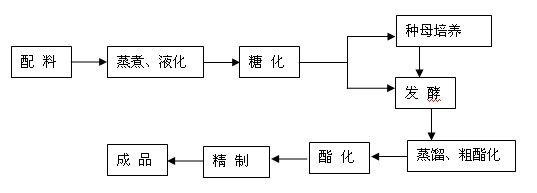

Method for producing ethyl acetate by taking starchiness as main raw materials

A starchy raw material, ethyl acetate technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high production cost, high energy consumption, and difficulty in comprehensive utilization of resources, and reduce production. cost, energy consumption reduction, production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

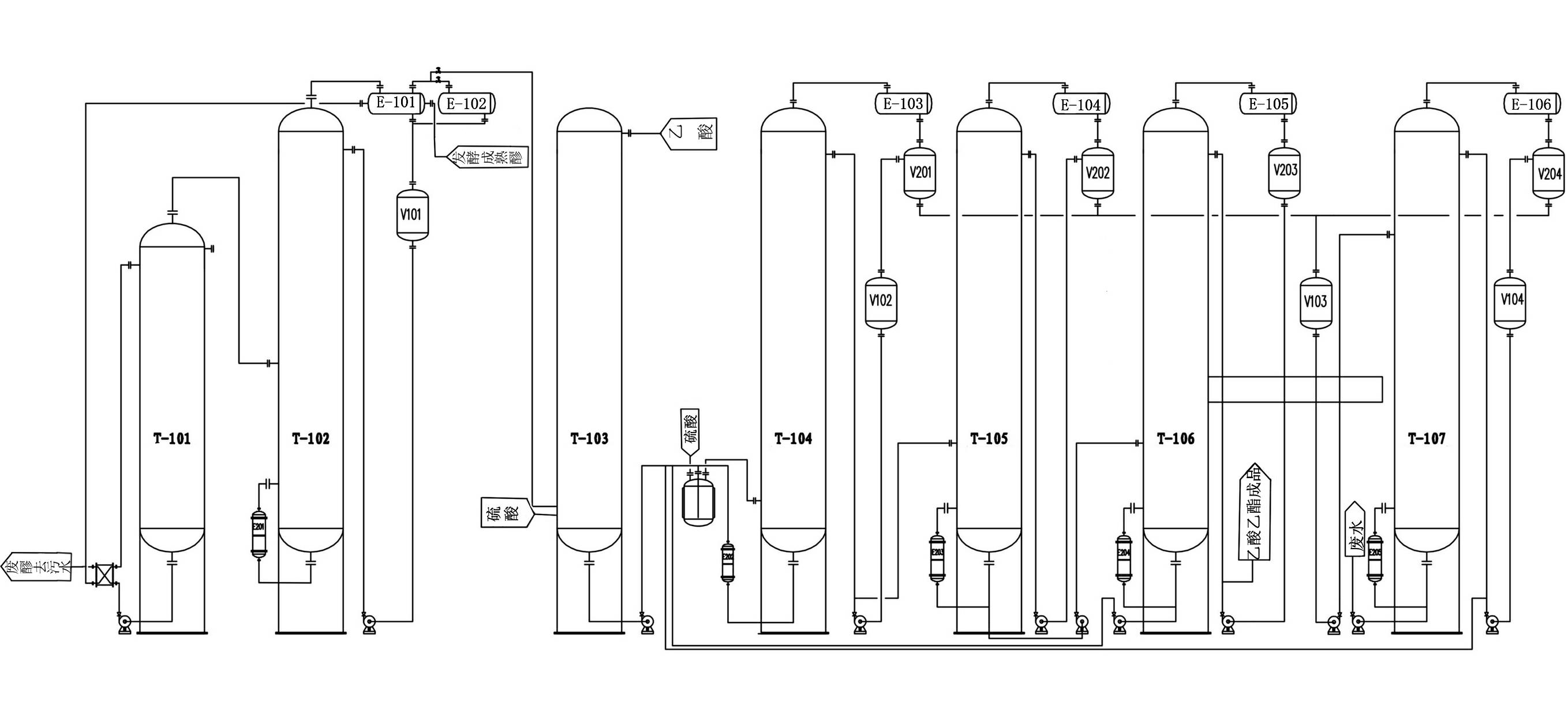

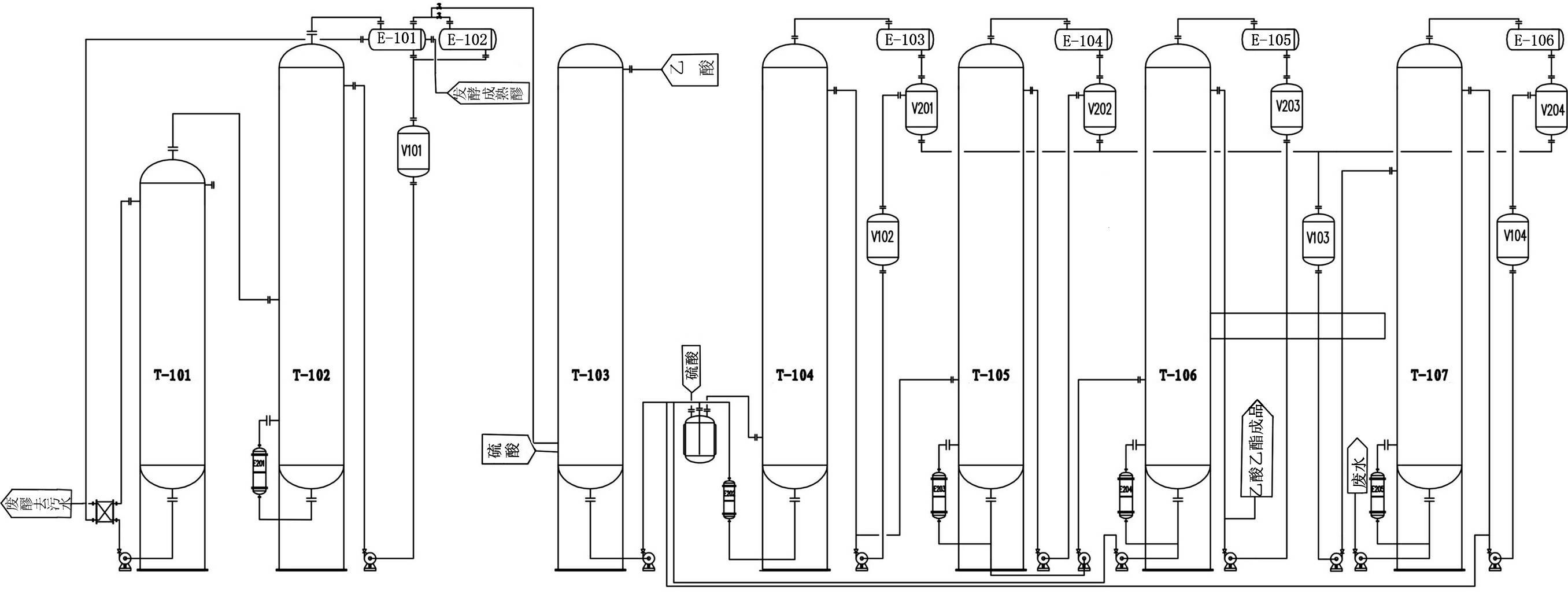

[0060] Taking starchy raw material as cassava as an example, the method for producing ethyl acetate of the present invention comprises the steps:

[0061] 1. Steps of crushing ingredients

[0062] Crush the cassava raw material and pass it through a sieve with a diameter of 1.2 mm to obtain the sieved material. Mix the sieved material with water at a mass ratio of 1:2.5, and control the temperature of the water at 55°C to obtain the mixed material. Feed liquid, the total sugar of mixed feed liquid is 18%;

[0063] 2. Cooking and liquefaction steps:

[0064] Cook the mixed feed liquid, keep the temperature at 90°C, and add liquefaction enzyme 6u / g starchy raw material, and the liquefaction time is 80 minutes to obtain the cooked and liquefied feed liquid;

[0065] 3. Saccharification steps:

[0066] After cooking and liquefaction, cool the above-mentioned cooking and liquefied feed liquid to 58°C, adjust the pH to 4 with concentrated sulfuric acid with a mass concentration o...

Embodiment 2

[0081] Taking starchy raw material as cassava as an example, the method for producing ethyl acetate of the present invention comprises the steps:

[0082] 1. Steps of crushing ingredients

[0083] Crush the cassava raw material and pass it through a sieve with a diameter of 1.5mm to obtain the sieved material. Mix the sieved material with water at a mass ratio of 1:2.7, and control the temperature of the water at 63°C to obtain the mixed material. Feed liquid, the total sugar of mixed feed liquid is 19%;

[0084] 2. Cooking and liquefaction steps:

[0085] Cook the mixed feed liquid, keep the temperature at 98°C, add liquefying enzyme 6u / g starchy raw material, and liquefy it for 90 minutes to obtain the cooked and liquefied feed liquid;

[0086] 3. Saccharification steps:

[0087] After cooking and liquefaction, cool the above-mentioned cooking and liquefied feed liquid to 60°C, adjust the pH to 4.2 with concentrated sulfuric acid with a mass concentration of 98%, add glucoa...

Embodiment 3

[0102] Taking starchy raw material as corn as an example, the method for producing ethyl acetate of the present invention comprises the steps:

[0103] 1. Steps of crushing ingredients

[0104] The corn raw material is crushed and passed through a sieve with a diameter of 1.8 mm to obtain the sieved material, and the sieved material and the gluten processing wastewater are mixed with a mass ratio of 1:3 to control the waste water from the gluten processing. The temperature is 70°C, and the mixed material liquid is obtained, and the total sugar of the mixed material liquid is 20%;

[0105] 2. Cooking and liquefaction steps:

[0106] Cook the mixed feed liquid, keep the temperature at 105°C, add liquefying enzyme 6u / g starchy raw material, and liquefy it for 100 minutes to obtain the cooked and liquefied feed liquid;

[0107] 3. Saccharification steps:

[0108] After cooking and liquefaction, cool the above-mentioned cooking and liquefied feed liquid to 62°C, adjust the pH to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com