A kind of anti-skid sealing layer composite material for road and preparation method thereof

A composite material and road technology, which is applied in the direction of roads, roads, coatings, etc., can solve the problems of poor adhesion of the road base, incomplete road maintenance, and low strength of the sealing film, so as to improve toughness, good road guidance, The effect of improving wear resistance

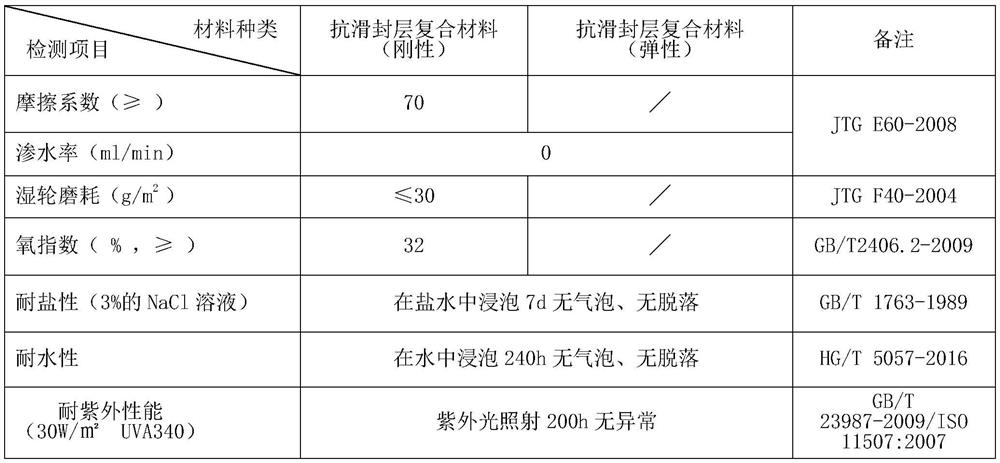

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Anti-Slip Seal Compound (Black Rigid):

[0043] First, prepare the phenol-terminated latex of polyurethane prepolymer according to the following steps

[0044] The first step, the preparation of polyurethane prepolymer

[0045] Accurately weigh 100 parts of polyether N210, and dehydrate in vacuum for 2 hours at a temperature of 120°C and a pressure of -0.09MPa. When the temperature drops to 50°C, add 31 parts of TDI-80, After reacting for 1 hour, the temperature was raised to 80° C. and then reacted for 3 hours. After the reaction was completed, vacuum defoaming was performed for 30 minutes to obtain a polyurethane prepolymer with a mass content of -NCO groups of 5%.

[0046] The second step, phenol capping reaction

[0047] (1) at first in 13 parts of phenol, add the dibutyltin dilaurate catalyst of 0.15 part, stir after standby;

[0048] (2) Add the polyurethane prepolymer prepared in the first step into the reactor, and after heating to 80°C, in the state of stirr...

Embodiment 2

[0057] Anti-Slip Seal Compound (Red Rigid):

[0058] First, prepare the phenol-terminated latex of polyurethane prepolymer according to the following steps

[0059] The first step, the preparation of polyurethane prepolymer

[0060] Accurately weigh 100 parts of polyether N210, and dehydrate in vacuum for 2 hours at a temperature of 120°C and a pressure of -0.09MPa. When the temperature drops to 50°C, add 44 parts of TDI-80, After reacting for 1 hour, the temperature was raised to 80° C. and then reacted for 3 hours. After the reaction was completed, vacuum defoaming was performed for 30 minutes to obtain a polyurethane prepolymer with a mass content of -NCO group of 9%.

[0061] The second step, phenol capping reaction

[0062] (1) First, add 0.2 parts of dibutyltin dilaurate catalyst to 24 parts of phenol, shake well and set aside;

[0063] Add the polyurethane prepolymer prepared in the first step into the reactor, and after heating to 80°C, add the phenol that has been ...

Embodiment 3

[0072] Anti-Slip Seal Compound (Green Elastic):

[0073] First, prepare the phenol-terminated latex of polyurethane prepolymer according to the following steps

[0074] Preparation of Polyurethane Prepolymer

[0075] Step 1: Accurately weigh 100 parts of polyether N210, and dehydrate in vacuum for 2 hours at a temperature of 120°C and a pressure of -0.09MPa. When the temperature drops to 50°C, add 37.3 parts of TDI-80. After reacting at 50°C for 1 hour, the temperature was raised to 80°C and then reacted for 3 hours. After the reaction was completed, vacuum defoaming was performed for 30 minutes to obtain a polyurethane prepolymer with a mass content of -NCO groups of 7%;

[0076] The second step, phenol capping reaction

[0077] (1) first add the dibutyltin dilaurate catalyst of 0.17 part in the phenol of 18.8 parts, stir after standby;

[0078] (2) Add the polyurethane prepolymer prepared in the first step into the reactor, and after heating to 80°C, in the state of stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com