Hydrogen sulfide treating agent for oil fields and method for treating hydrogen sulfide

A technology of hydrogen sulfide and treatment agent, which is applied in the direction of chemical instruments and methods, earth drilling, and drilling compositions, etc. It can solve the problems of fire or explosion, inability to completely kill sulfate-reducing bacteria, and high cost, and achieve the goal of inhibiting active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of hydrogen sulfide treatment agent: Take 80 kg of polyaspartic acid, 10 kg of glycerin, 50 kg of protease, 10 kg of beef powder, 5 kg of sodium magnesium edetate, 160 kg of potassium chloride, 10 kg of ferric chloride, 2.5 kg of manganese sulfate, 2.5 kg of zinc sulfate, 2 kg of copper sulfate, 15 kg of sodium molybdate, 4 kg of cobalt chloride and 5 kg of nickel chloride, 1.5 kg of vitamin B5, 1.5 kg of microbial B12 and 1 kg of D-biotin, Mix in a reaction kettle, add 640 kg of deionized water, fully stir and dissolve, and make a water-soluble microbial activation system.

[0040] Take 150 kilograms of calcium nitrate, 100 kilograms of potassium nitrite, 80 kilograms of water-soluble microorganism activation system, take 670 kilograms of deionized water, put them in a reaction kettle, stir at a speed of 60r / min for 1 hour until all are dissolved and mixed uniformly, and obtained Hydrogen sulfide treatment agent.

Embodiment 2

[0042] Hydrogen sulfide treatment agent preparation: take 60 kg of polyaspartic acid, 100 kg of protease, 30 kg of beef powder, 150 kg of potassium chloride, 10 kg of ferric chloride, 15 kg of sodium molybdate, 5 kg of cobalt chloride and 5 kg Nickel chloride, 2 kg of vitamin B5 and 2 kg of D-biotin were mixed in a reaction kettle, 621 kg of deionized water was added, fully stirred and dissolved, and a water-soluble microbial activation system was made.

[0043] Take 180 kilograms of calcium nitrate, 90 kilograms of potassium nitrite, 60 kilograms of water-soluble microorganism activation system, and 670 kilograms of deionized water, put them in a reaction kettle, stir at a rotating speed of 60r / min for 1 hour until they are completely dissolved and mixed, and the obtained Hydrogen sulfide treatment agent.

Embodiment 3

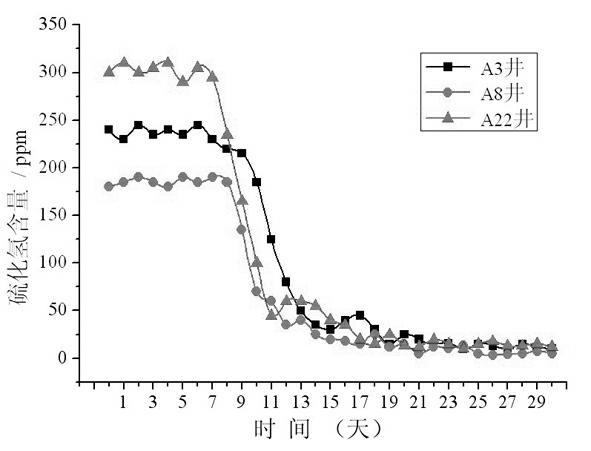

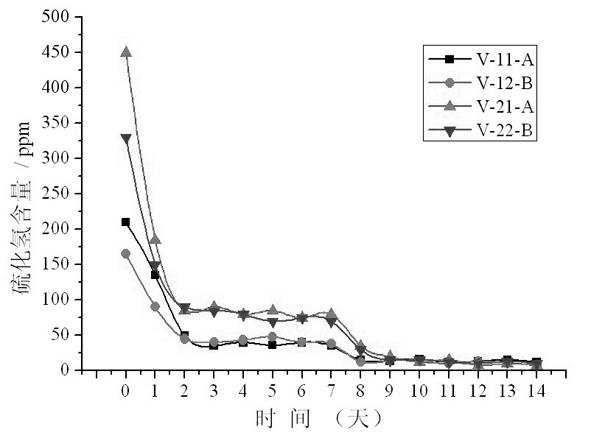

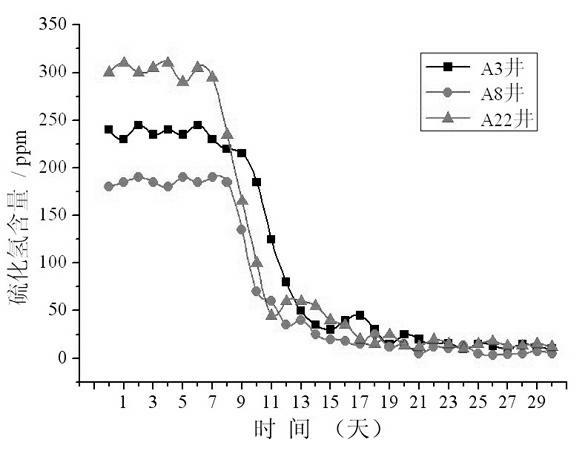

[0045] The method of the present invention controls hydrogen sulfide on the CNOOC oilfield platform:

[0046] 1. Hydrogen sulfide pollution status of oilfield platforms

[0047] There is relatively serious hydrogen sulfide pollution in the oil field. Hydrogen sulfide is produced in the early stage of well group production, and the content reaches 500-1000ppm; some well groups also produce hydrogen sulfide with the extension of water injection time, and the content reaches 100-500ppm; Tracking and monitoring of hydrogen sulfide content and sulfate-reducing bacteria content confirmed that the hydrogen sulfide in the oilfield contains both biogenic hydrogen sulfide and non-biogenic hydrogen sulfide.

[0048] 2. Analysis of the structure and properties of the flora

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com