Combined method for treating refinery wastewater by adopting reverse osmosis and catalytic ozonation

A technology for ozone catalytic oxidation and oil refinery wastewater, applied in the direction of oxidation water/sewage treatment, permeation/dialysis water/sewage treatment, chemical instruments and methods, etc., can solve the problem of difficult discharge standards, poor biochemical properties, and incomplete removal of pollutants And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

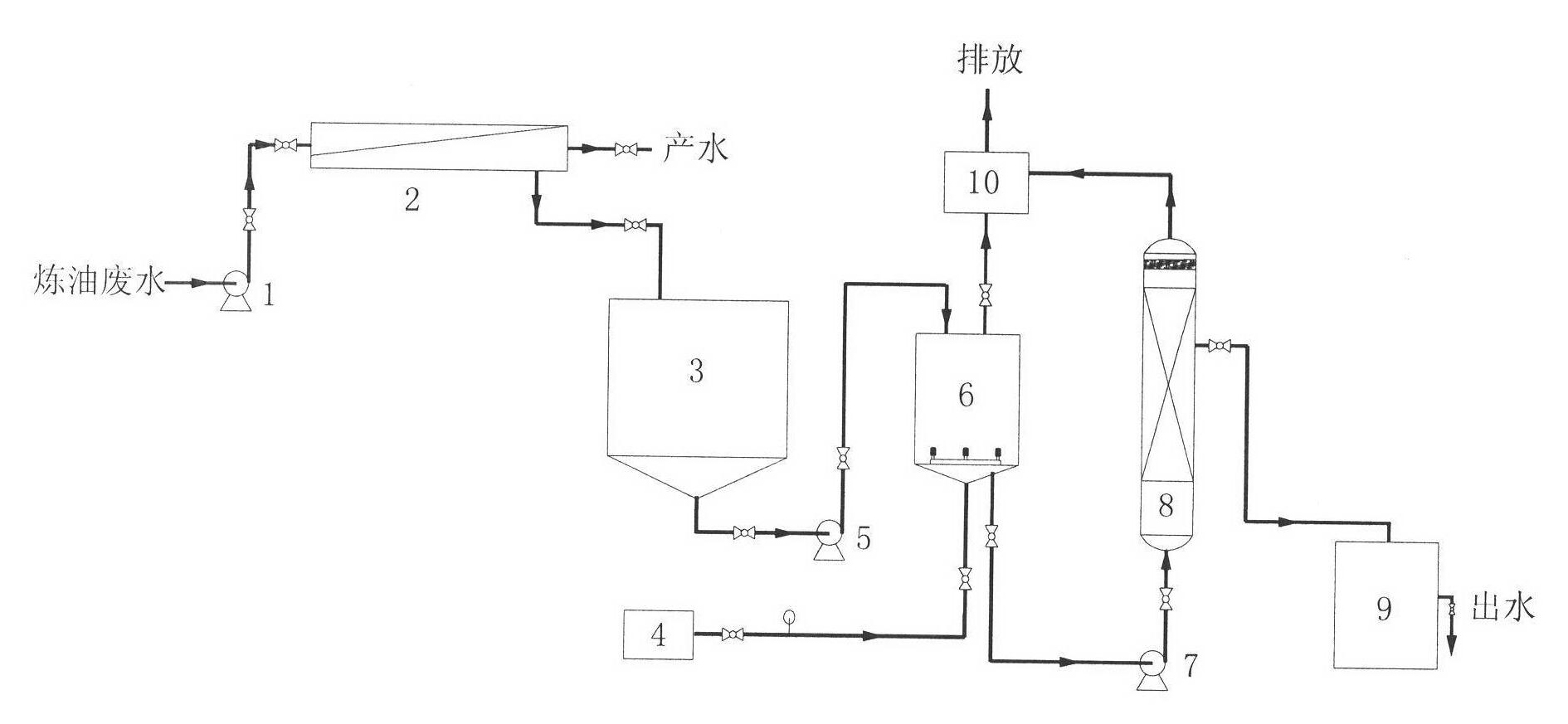

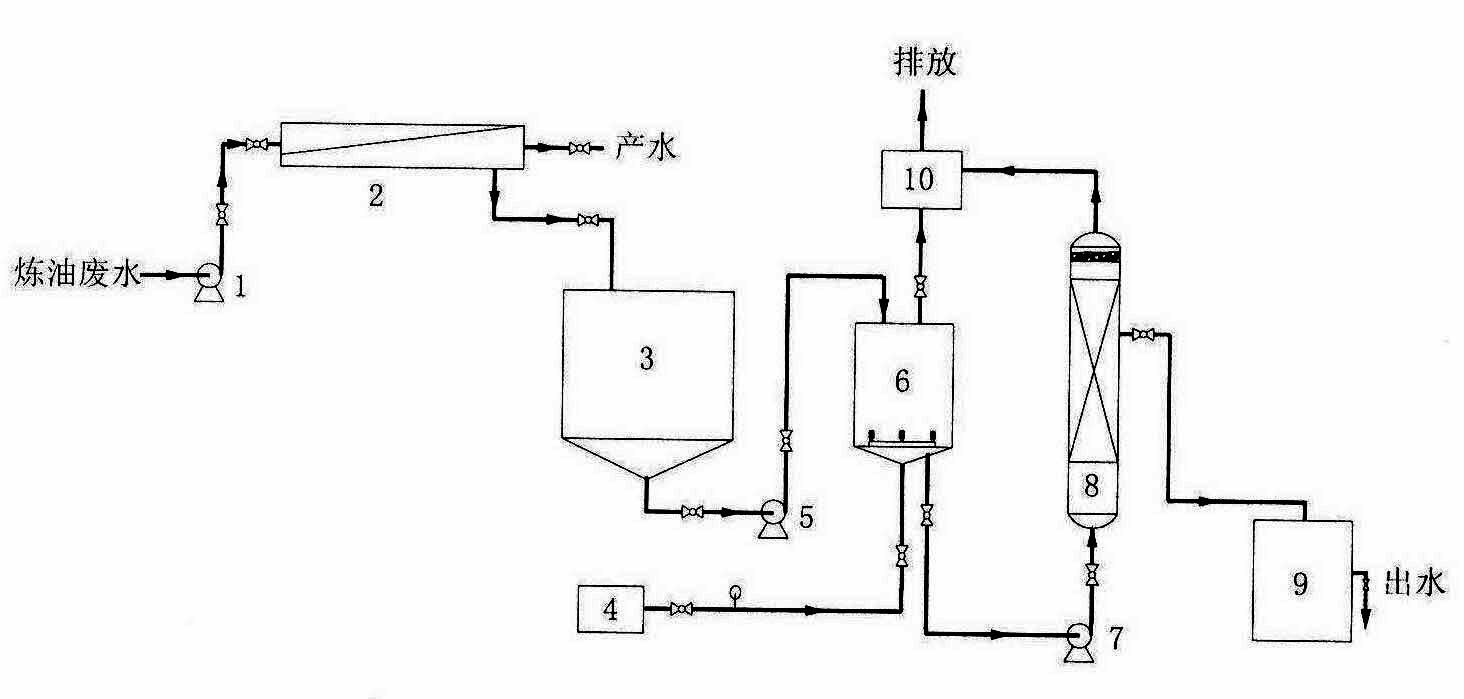

[0011] An oil refinery in Zhejiang, daily treatment of refining wastewater 1200m 3 , in order to realize sewage reuse, adopt reverse osmosis of the present invention and ozone catalytic oxidation advanced treatment oil refinery wastewater combined process method, carried out pilot test research on the spot, specific implementation process is as attached figure 1 : The ultrafiltration product water enters the reverse osmosis membrane 2 through the high-pressure pump 1, and the produced water is reused in the production process. The tank is fully mixed and reacted with the ozone provided by the ozone generator 4 , the effluent enters the catalytic oxidation reaction tower 8 through the lift pump 7 , and the effluent flows into the clear water pool 9 . The tail gas discharged from the pre-aeration tank 6 and the catalytic oxidation reaction tower 8 enters the tail gas purifier 10, and the purified gas is discharged.

[0012] When the operating pressure difference of the reverse ...

Embodiment 2

[0014] A refinery in Tianjin treats 1800m of refinery waste water per day 3 , in order to realize sewage reuse, adopt reverse osmosis of the present invention and ozone catalytic oxidation advanced treatment refinery waste water combined process method to carry out small-scale experimental research on the spot, implementation process is the same as embodiment one: when reverse osmosis membrane 2 operating differential pressure is controlled at At 0.9MPa, reverse osmosis influent CODcr45~52mg / L, conductivity 3350~3620us / cm, petroleum 1.3~2.0mg / L, after reverse osmosis treatment, reverse osmosis product water CODcr0mg / L, conductivity 138~156us / cm, petroleum 0mg / L. Reverse osmosis concentrated water COD180~210mg / L, petroleum 5.2~7.4mg / L, when the ozone dosage in the water is 10~15mg / L, the mixing reaction time in the pre-aeration tank 6 is controlled at 15~20min, and the catalytic oxidation reaction The air speed of tower 8 is controlled at 3.0~3.5h -1 When treated by the ozon...

Embodiment 3

[0016] A refinery in Heilongjiang treats 3000m of refinery waste water per day 3 , in order to realize the reuse of sewage, the combination process of reverse osmosis and ozone catalytic oxidation advanced treatment of oil refinery wastewater of the present invention was carried out in a small test on site. The implementation process is the same as that of Example 1: when the operating pressure difference of the reverse osmosis membrane 2 is controlled at 0.9MPa, the reverse osmosis influent CODcr32~42mg / L, conductivity 2650~2930us / cm, petroleum 0.8~1.5mg / L, after reverse osmosis After osmosis treatment, reverse osmosis produced water CODcr0mg / L, conductivity 89-106us / cm, petroleum 0mg / L. Reverse osmosis concentrated water COD 130-170mg / L, petroleum 2.8-4.2mg / L, when the amount of ozone in the water is 5-10mg / L, the mixing reaction time in the pre-aeration tank 6 is controlled at 20-30min, catalytic oxidation The space velocity of reaction tower 8 is controlled at 2.0~2.5h -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com