Method for preparing carbon fiber cloth material capable of effectively purifying air

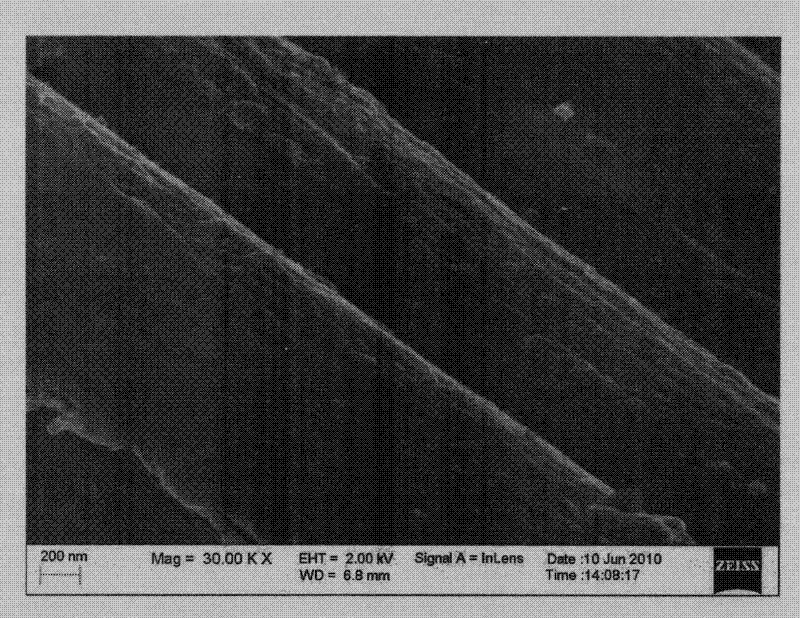

The technology of carbon fiber cloth and activated carbon fiber cloth is applied in the field of sol-gel process doped with rare earth elements, anatase type nano-titanium dioxide film, and carbon fiber cloth material, and achieves the advantages of strong binding force, strong sterilization ability, and improved photocatalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

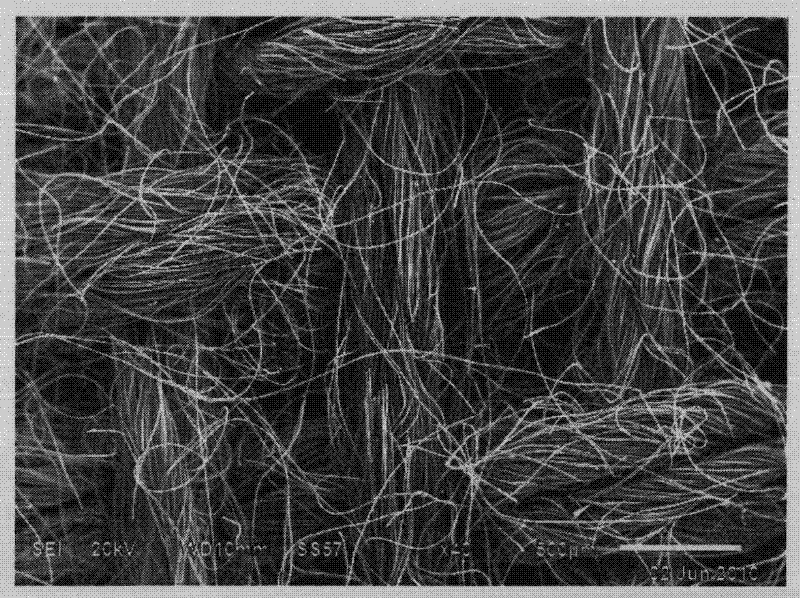

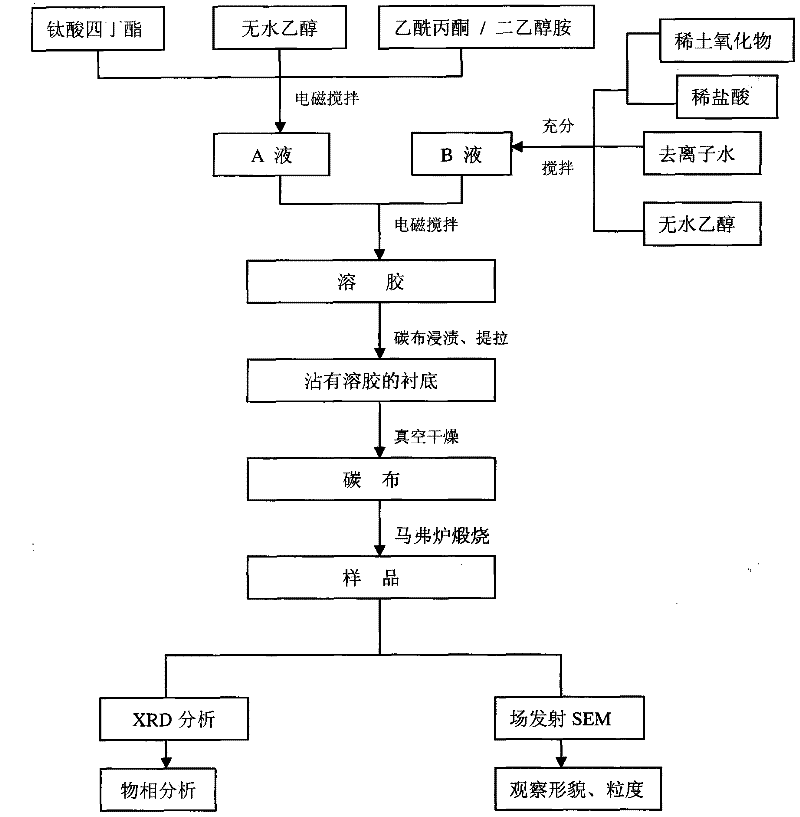

[0015] Activated carbon fiber cloth loaded with nano-TiO2 was prepared by sol-gel process.

[0016] Raw materials: tetrabutyl titanate (purity ≥ 98.0%) 20ml, acetylacetone (purity ≥ 98.0%) 3ml, absolute ethanol (purity ≥ 99.7%) 55ml, dilute hydrochloric acid (concentration 4%) 2ml, deionized water 20ml, Activated carbon fiber cloth 300×200mm, rare earth oxide (mass ratio La2O3:Y2O3:Eu2O3=1:2:1) 0.17g (calculated by 0.8wt.%).

[0017] First prepare the sol, take 3ml of acetylacetone dropwise into 50ml of absolute ethanol and stir thoroughly, then add 20ml of butyl titanate to make solution A; dissolve the rare earth oxide in 2ml of dilute hydrochloric acid, and then measure 3.5ml of anhydrous Add ethanol and 17.5ml deionized water into it and mix thoroughly to make solution B; then slowly drop solution B into the stirred solution A with a rubber dropper, and stir fully for an appropriate time to obtain a light yellow sol.

[0018] Perform acetone ultrasonic degreasing and deco...

Embodiment 2

[0022] The sol was prepared by using diethanolamine instead of acetylacetone, so as to further prepare the activated carbon fiber cloth loaded with nano-TiO2.

[0023] Raw materials: tetrabutyl titanate (chemically pure, purity ≥ 98.0%) 17.02ml, diethanolamine (analytical pure, purity ≥ 99.0%) 4.08ml, absolute ethanol (analytical pure, purity ≥ 99.7%) 80ml, dilute hydrochloric acid ( Concentration 4%) 2ml, rare earth oxide (mass ratio La2O3:Y2O3:Eu2O3=1:2:1) 0.2g (calculated by 0.8wt.%), activated carbon fiber cloth 300×200mm, deionized water 0.9ml.

[0024] Configure the sol: take 17.02ml of butyl titanate and put it into a 500ml beaker, add 67.28ml of absolute ethanol, and add 4.08ml of diethanolamine as an inhibitor, stir well to prepare a solution; take 0.2g of rare earth oxide and dissolve it in 2ml In dilute hydrochloric acid, add 0.9ml of deionized water and 10ml of absolute ethanol, and stir thoroughly to obtain liquid B; slowly add liquid B to the stirred liquid A wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com