Optical engine for projector

An optical engine and projector technology, applied in the field of projection display, can solve the problems of complex optical structure, poor spot shaping and uniform light effect, large light energy loss, etc., to achieve uniform energy distribution, miniaturization of the whole machine, and high light energy. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

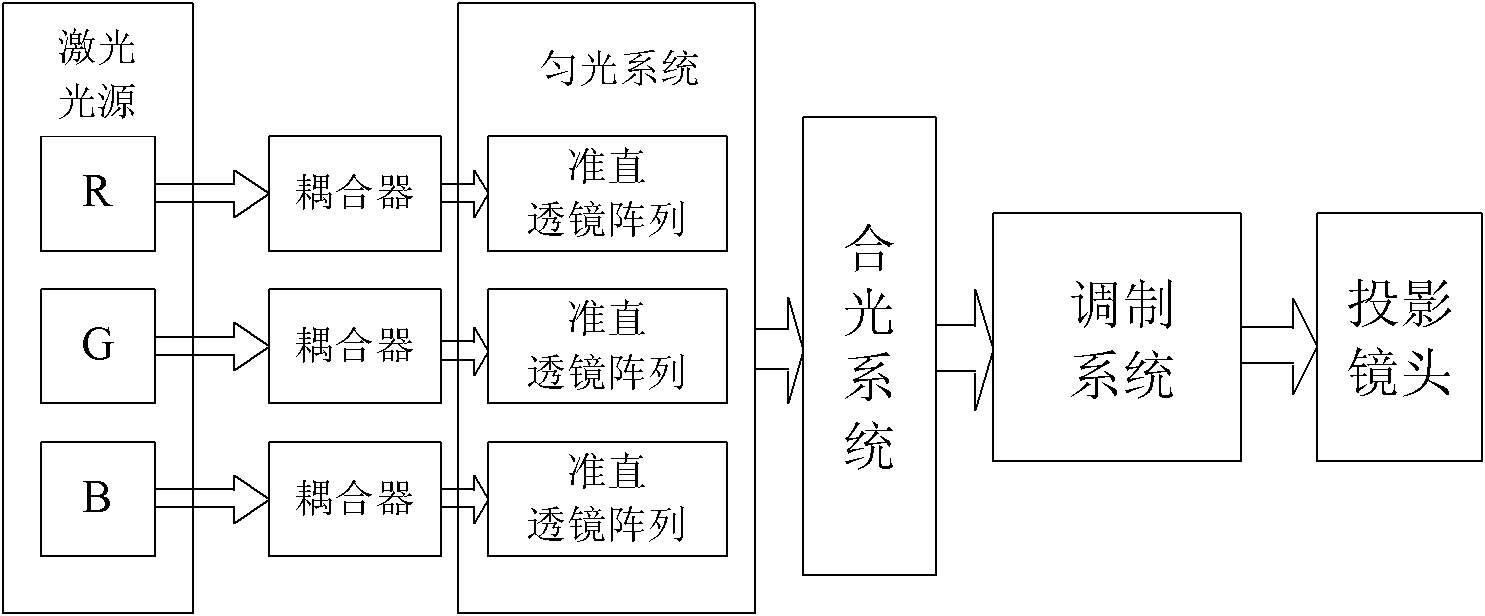

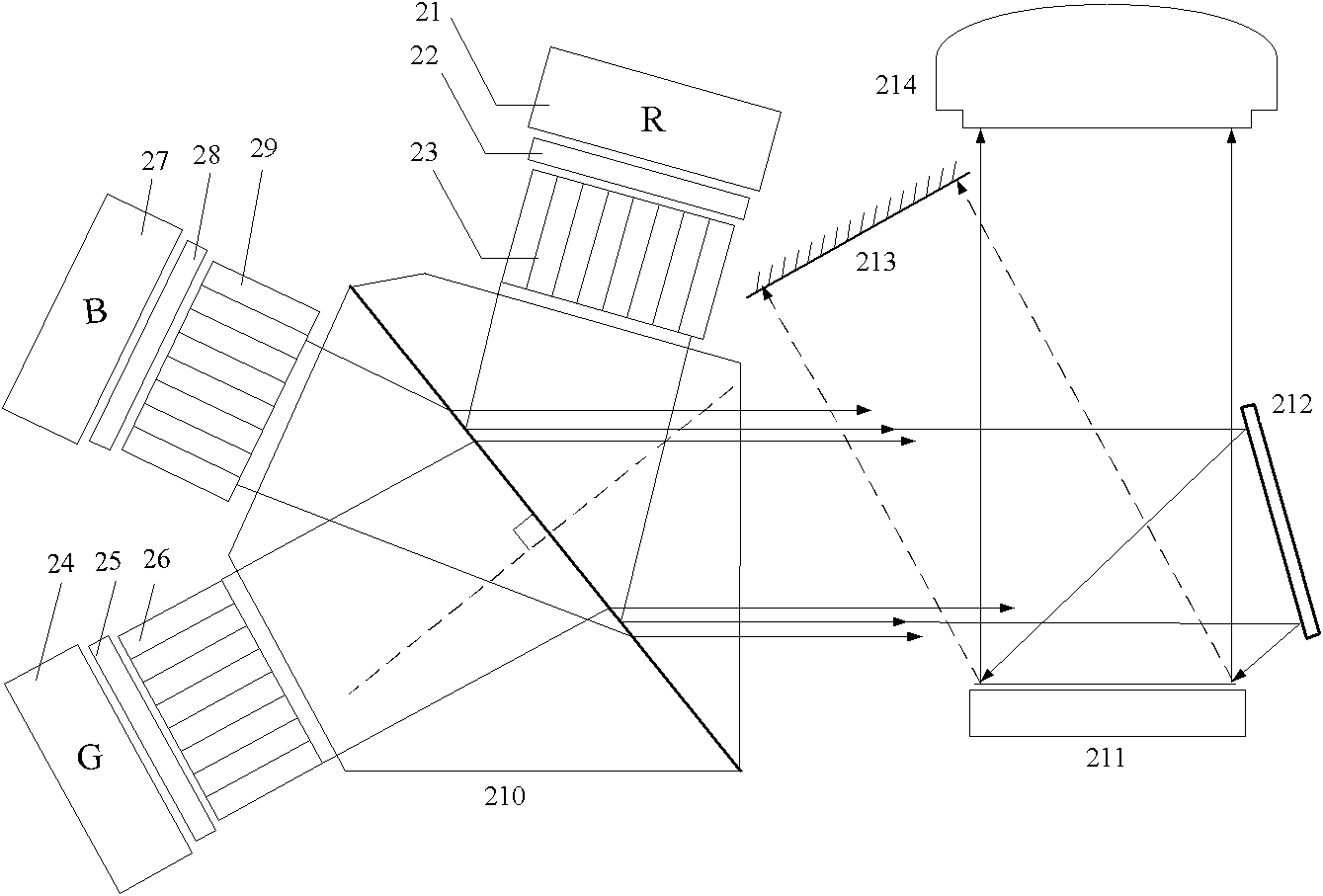

[0031] The first embodiment of the present invention is applicable to the optical engine of a monolithic DMD or LCoS optical modulator. like figure 2 As shown, the optical engine includes: RGB tricolor laser light sources 21, 24, 27, three beam couplers 22, 25, 28, three collimating lens arrays 23, 26, 29, and a Wollaston light combining prism 210 , light modulator components 211 , 212 , 213 , projection lens 214 .

[0032] The light source adopts laser light source, providing RGB three primary colors. A color uses at least one laser. The driving method of the light source adopts the time-mixing method, that is, the three RGB light sources sequentially emit sequential light pulses within one frame time, and the monochrome pulse width is divided according to the white balance. Full color display.

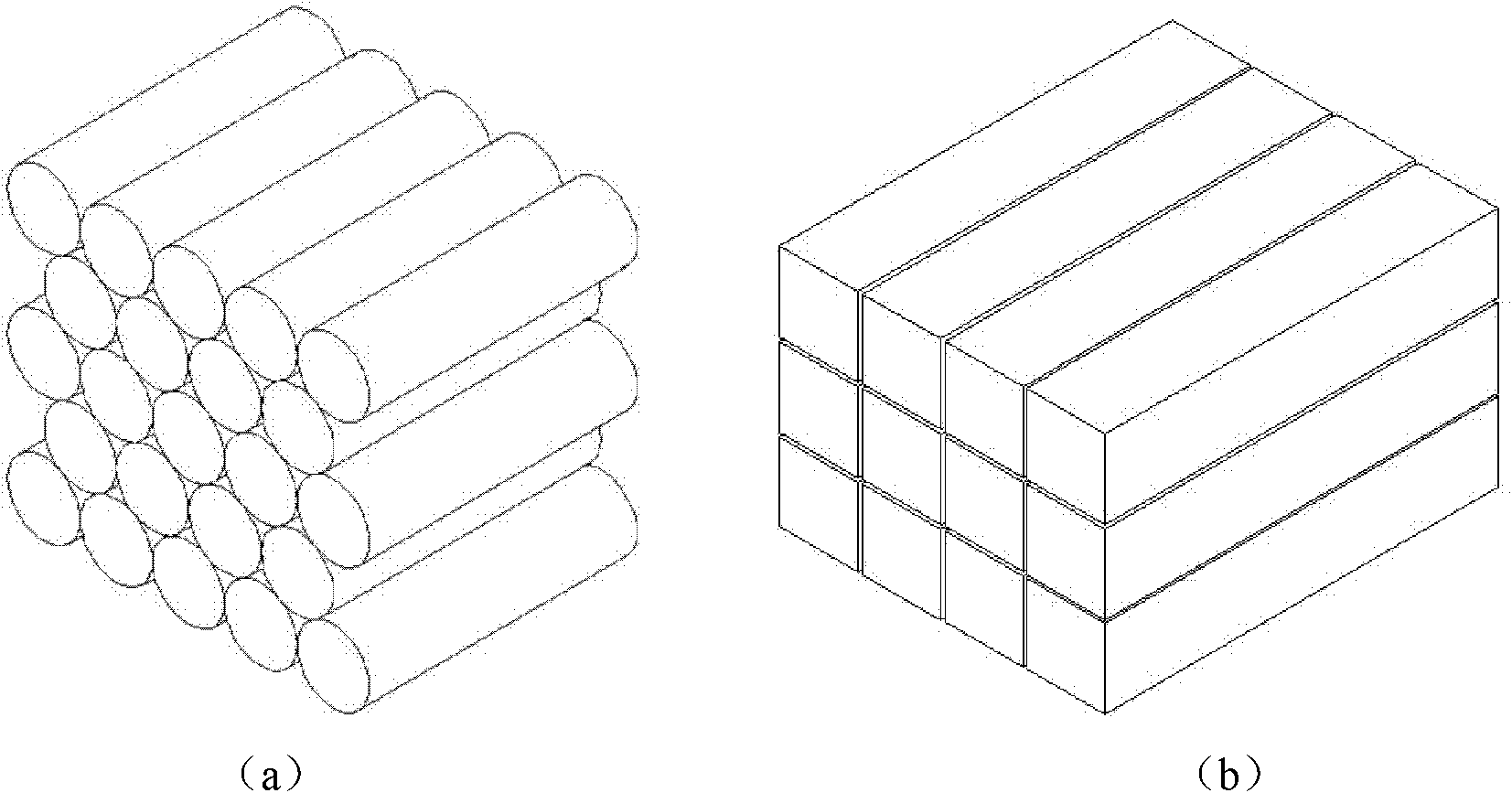

[0033] The beam coupler is used to realize the optical connection between the laser light source and the collimating lens array. The connection method between the monochromatic...

no. 2 approach

[0046] The second embodiment of the present invention is applicable to the optical engine of a monolithic DMD or LCoS optical modulator. The second embodiment is improved on the basis of the first embodiment. The improvement is that the X prism is used instead of the Wollaston prism to combine light. Such as Figure 7 As shown, the X prism 81 is formed by splicing the right angles of four right-angle prisms. R light: full transmission of ab surface and cd surface; G light: total reflection of ab surface, full transmission of cd surface; B light: total reflection of cd surface, full transmission of ab surface. The synthesized light is emitted through the bd surface and projected to the light modulator. Its characteristic is that there is no need to consider the polarization of the laser, and the device for obtaining the polarization and the device for shaping the combined light output end are removed, and the structure is further simplified.

no. 3 approach

[0048] The third embodiment of the present invention is applicable to the optical engine of a monolithic DMD or LCoS optical modulator. The third embodiment is improved on the basis of the first embodiment and the second embodiment. The improvement is that the light-combining prism adopts three-component color mirrors. Such as Figure 8 As shown, 91 mirrors fully reflect B light; 92 mirrors fully transmit B light, fully reflect G light; 93 mirrors fully transmit B and G light, and fully reflect R light. The light is combined by 93 mirrors and projected to the modulator. Compared with the X prism, the reflector has a simpler structure, less optical path loss, higher utilization rate of light energy, and lower manufacturing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com