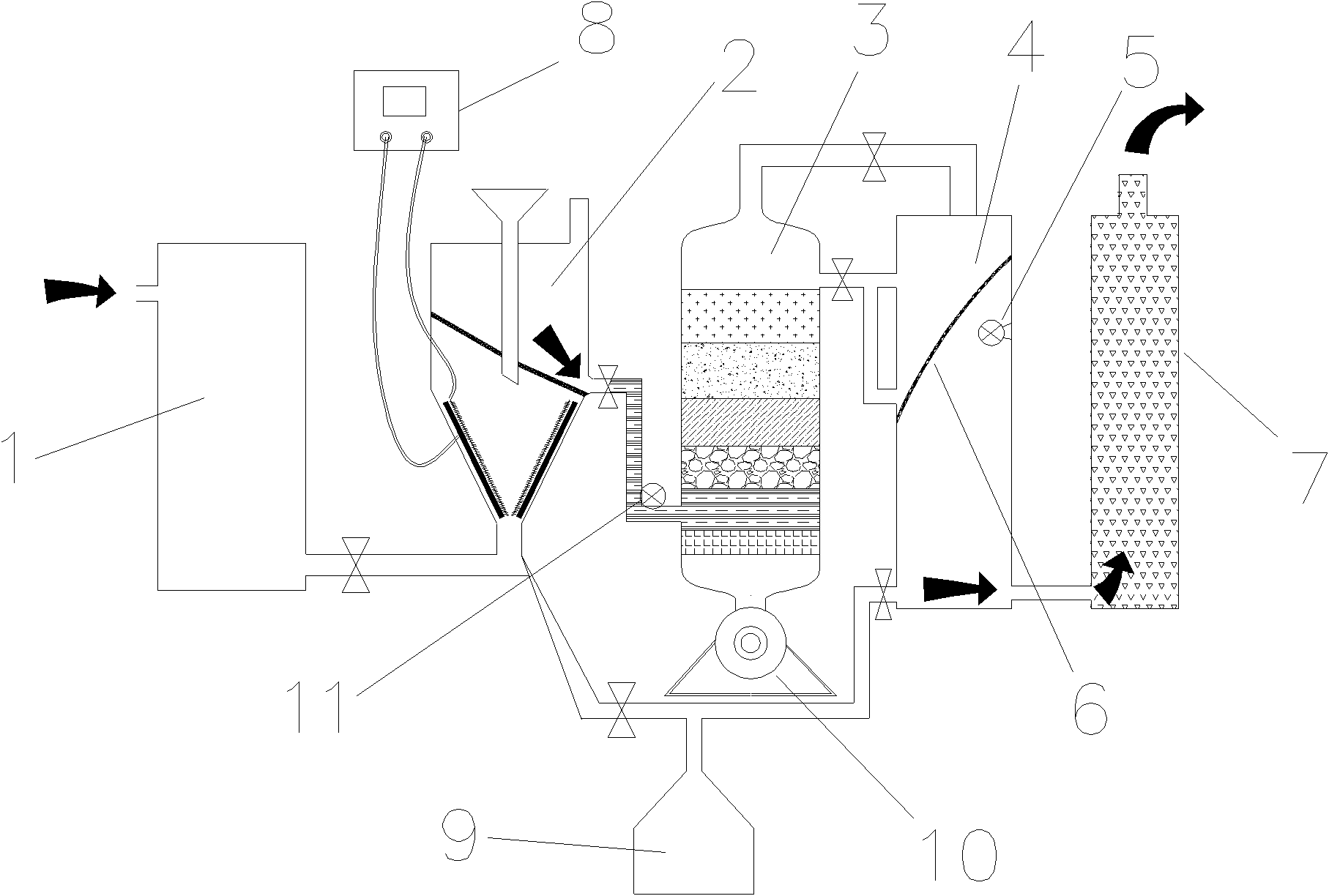

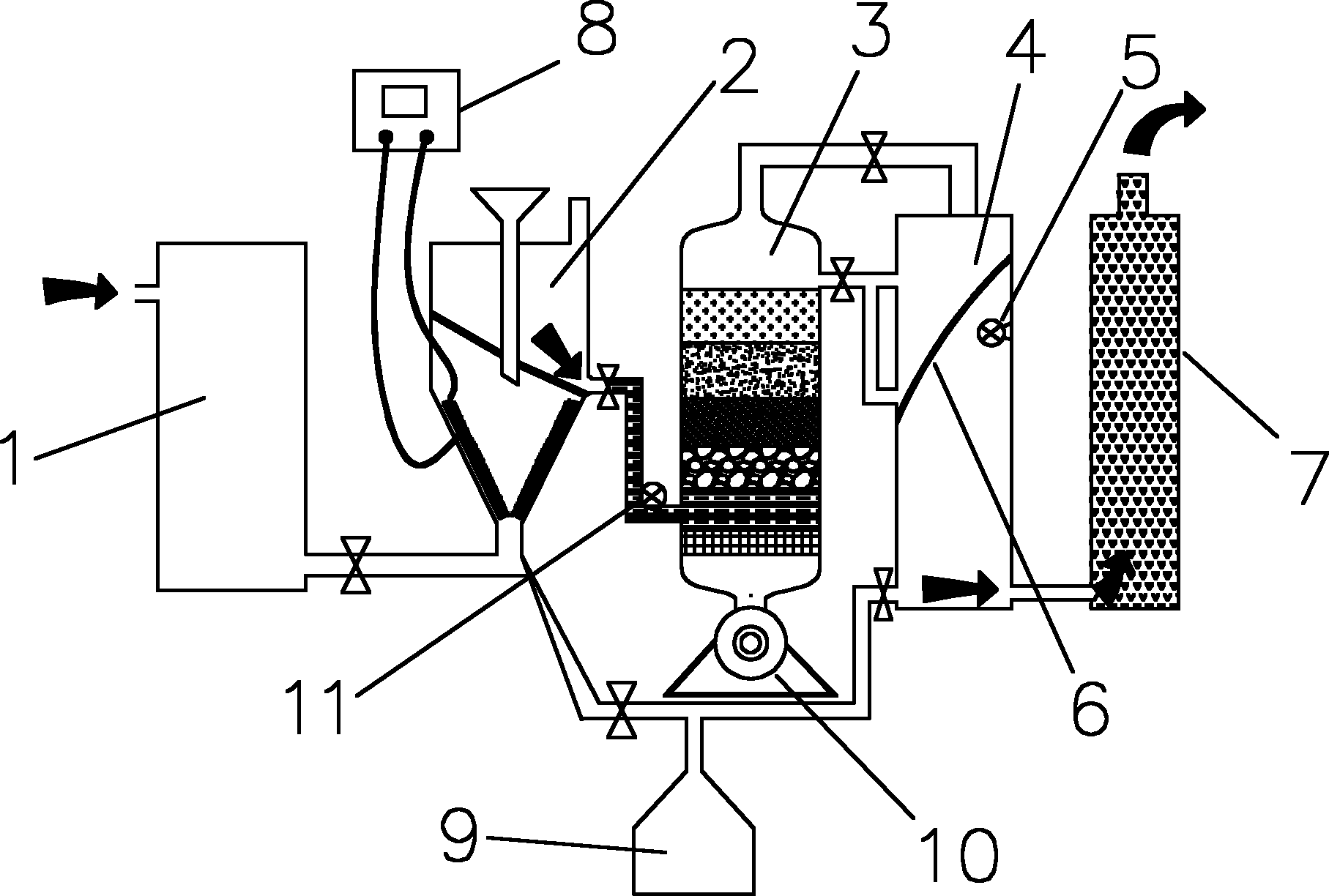

Device and method for processing restaurant wastewater

A technology for catering wastewater and wastewater, applied in the field of water treatment, can solve the problems of large floor space, large one-time investment, and increase the uncertainty factors of electroflocculation reaction, so as to prevent the blocking of membrane pores, improve the service life, and improve the quality of the effluent. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] Example 1: The source of wastewater is catering wastewater from a restaurant, and the water quality condition is: COD cr The content is 3500~5000mg / L, BOD 5 The content is 1500~2000mg / L, the SS content is 1000mg / L, and the ammonia nitrogen content is 900mg / L. Set the DC pulse current intensity to 6A, the DC pulse period to 0.2Hz, the duty cycle to 0.6, the UV lamp power to 5W, and the sand filter layer height of the microporous sand filter tank to 100cm, the final effluent quality is: COD cr Content less than 100mg / L, BOD 5 The content of ammonia nitrogen is less than 60mg / L, the content of SS is less than 5mg / L, the concentration of ammonia nitrogen is less than 20mg / L, the removal rate of pollutants is over 90%, and the effluent can be reused as miscellaneous water.

example 2

[0048] Example 2: The source of wastewater is catering wastewater from a hotel, and the water quality condition is: COD cr The content is 3000~4500mg / L, BOD 5 The content is 1400~1800mg / L, the SS content is 980mg / L, and the ammonia nitrogen content is 850mg / L. Set the DC pulse current intensity to 6A, the DC pulse period to 0.2Hz, the duty cycle to 0.6, the UV lamp power to 5W, and the sand filter layer height of the microporous sand filter tank to 100cm, the final effluent quality is: COD cr Content less than 90mg / L, BOD 5 The content of ammonia nitrogen is less than 60mg / L, the content of SS is less than 5mg / L, the concentration of ammonia nitrogen is less than 20mg / L, the removal rate of pollutants is over 90%, and the effluent can be reused as miscellaneous water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com