Method for recovering phosphorus in crystallization way from semiconductor industrial waste water

A technology for producing wastewater and semiconductors, applied in chemical instruments and methods, phosphorus compounds, multi-stage treatment of water/sewage, etc., can solve the problems of difficulty in recycling phosphorus resources, low technical stability, complex operation and operation, and achieve low equipment investment. , Significant environmental benefits, easy operation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

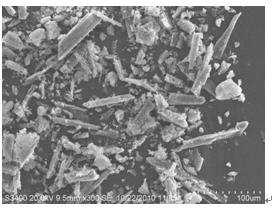

Image

Examples

Embodiment 1

[0031] The semiconductor production wastewater sample A was passed into the reaction vessel, and the contents of the main pollutants were: phosphorus concentration c(PO 4 3- -P)=120mg / L, ammonia nitrogen concentration c(NH 4 + -N)=30mg / L, fluoride ion concentration c(F - )=940mg / L. Add magnesium chloride and ammonium chloride to the wastewater, so that the molar ratio of each component ion in the reaction system is: magnesium salt: ammonia nitrogen: phosphate = 1.2~1.7: 2.0~2.5:1. Add pH adjusting solution to the waste liquid to make the pH value 8.8-9.3. Stir mechanically for 30 minutes with a double-blade single-blade stirring paddle at a stirring speed of 100 rpm. During the initial stage of stirring for 12 minutes, the temperature of the waste liquid is gradually increased from 18°C to 30°C and stabilized. After the stirring is completed, the waste liquid returns to the natural water temperature, gravity sediments for 60 minutes, separates the supernatant liquid fro...

Embodiment 2

[0033] The semiconductor production wastewater sample B was passed into the reaction vessel, and the contents of the main pollutants were: phosphorus concentration c(PO 4 3- -P)=170mg / L, ammonia nitrogen concentration c(NH 4 + -N)=100mg / L, fluoride ion concentration c(F - )=870mg / L. Add magnesium chloride to the waste water, so that the molar ratio of the ions of each component in the reaction system is: magnesium salt: ammonia nitrogen: phosphate = 1.3~1.8: 3.1~3.4:1. Add pH adjusting solution to the waste liquid so that the pH value is 8.9-9.4, and use a double-bladed single-blade stirring paddle to mechanically stir for 35 minutes at a stirring speed of 100 rpm. Within 10 minutes of the initial stage of stirring, gradually increase the temperature of the waste liquid from 20°C to 35°C and stable. After the stirring is completed, the waste liquid returns to the natural water temperature, gravity sediments for 60 minutes, separates the supernatant liquid from the crystal...

Embodiment 3

[0035] The semiconductor production wastewater sample C was passed into the reaction vessel, and the contents of the main pollutants were: phosphorus concentration c(PO 4 3- -P)=250mg / L, ammonia nitrogen concentration c(NH 4 + -N)=210mg / L, fluoride ion concentration c(F - )=1330mg / L. Add magnesium chloride to the wastewater, so that the molar ratio of the ions of each component in the reaction system is: magnesium salt: ammonia nitrogen: phosphate = 1.2~1.6: 4.2~4.5:1. Add pH adjusting solution to the waste liquid so that the pH value is 8.5-9.1, mechanically stir with double blades and double paddles for 40 minutes, the stirring speed is 80rpm, within 9 minutes of the initial stage of stirring, gradually increase the temperature of the waste liquid from 20°C to 33°C and stable. After the stirring is completed, the waste liquid returns to the natural water temperature, and the gravity sedimentation is carried out for 70 minutes. The supernatant liquid is separated from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com