Method for rapidly manufacturing industrial salt by utilizing sylvine mine and device

A technology of potassium salt ore and industrial salt, which is applied in the field of rapid production of industrial salt from potash ore, can solve the problems of high impurity content, large water consumption, shortage of resources and raw materials, etc., and achieve broad application prospects, advantages of energy saving and consumption reduction, The effect of fast evaporation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

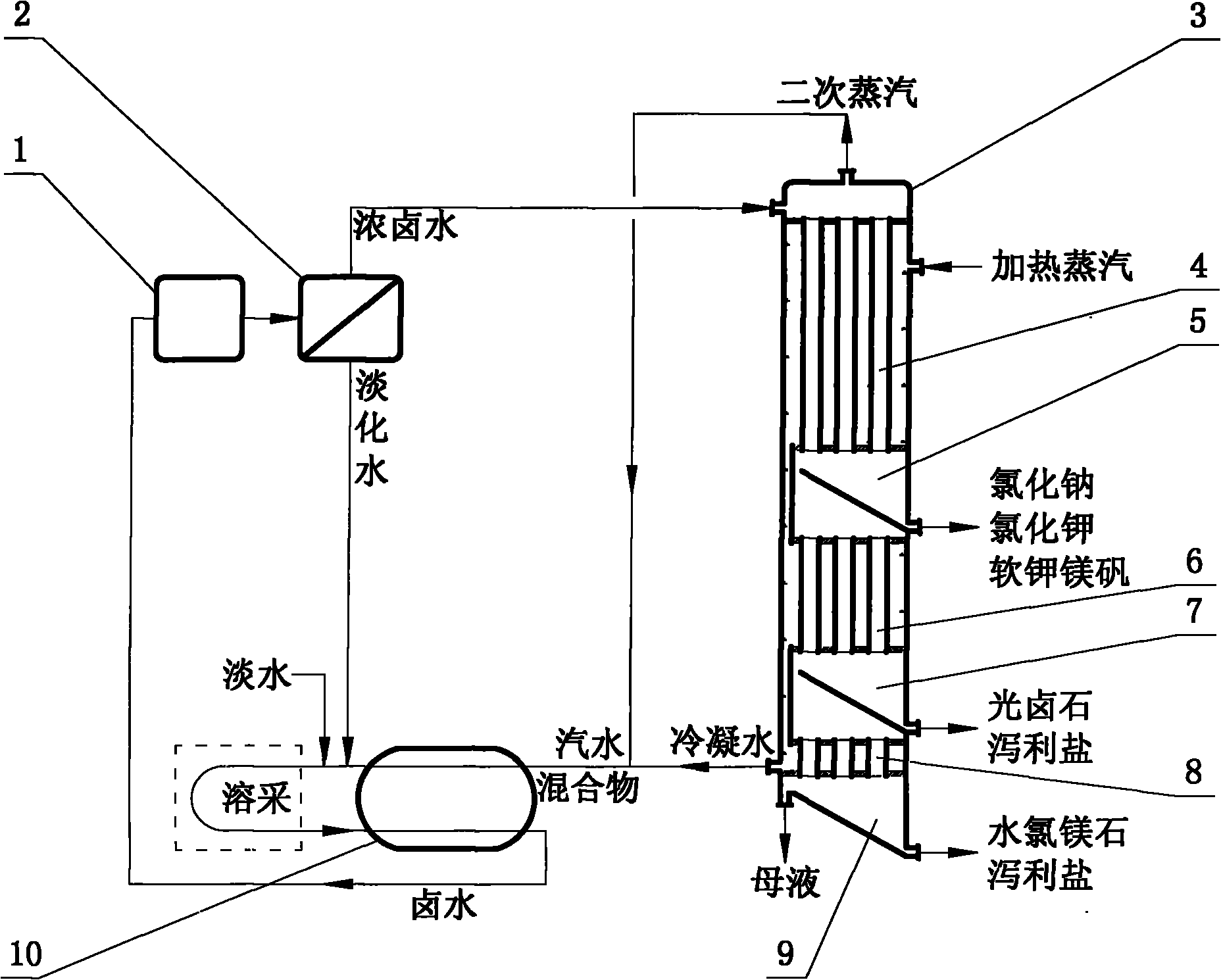

Embodiment 1

[0018] The raw materials used are taken from potash mines in the salt lake area of the Qaidam Basin in Qinghai. The brine obtained after solution mining of potash mines contains 12.53% NaCl, 1.25% KCl, and 12.77% MgCl 2 , 4.01% Na 2 SO 4 . The device for producing industrial salt adopts figure 1 In the shown device, the heat source of the heater 1 is solar energy, and the desalinator 2 is a membrane still.

[0019] The operation flow of the rapid production of industrial salt from potash mine: the brine is heated to 95°C in the heater 1, enters the desalinator 2 and is separated into desalinated water and nearly saturated concentrated brine, and the concentrated brine enters the evaporator 3; the evaporator 3, the heat exchange area ratio of the first heating chamber 4, the second heating chamber 6, and the third heating chamber 8 is 5:2:1 in turn, and the heating steam flows in the first heating chamber 4, the second heating chamber 6, and the third heating chamber in tu...

Embodiment 2

[0022] The raw materials used are taken from potash mines in the salt lake area of the Qaidam Basin in Qinghai. The brine obtained after solution mining of potash mines contains 6.01% NaCl, 7.10% KCl, and 10.22% MgCl 2 , 6.12% Na 2 SO 4 . The device for producing industrial salt adopts figure 1 In the shown device, the heat source of the heater 1 is factory waste heat, and the desalinator 2 is a humidifier-dehumidifier.

[0023] The operation process of the potash salt ore rapid production industrial salt device is the same as that of Example 1, except that the brine is heated to 90°C in the heater 1, and the first heating chamber 4, the second heating chamber 6, and the third heating chamber in the evaporator 3 The heat exchange area ratio of the heating chamber 8 is 10:2.2:1, and the concentrated liquid phase volumes in the first evaporating chamber 5, the second evaporating chamber 7 and the third evaporating chamber 9 are respectively controlled to 31% of the original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com