Method for processing fermented type nutritional fruit and vegetable powder rich in vitamin

A processing method and a fermentation-type technology are applied in the processing field of fermented nutritious fruit and vegetable powder, which can solve the problems of being difficult to meet new requirements of consumers, and achieve the effects of increasing comprehensive economic benefits, reducing waste of resources and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

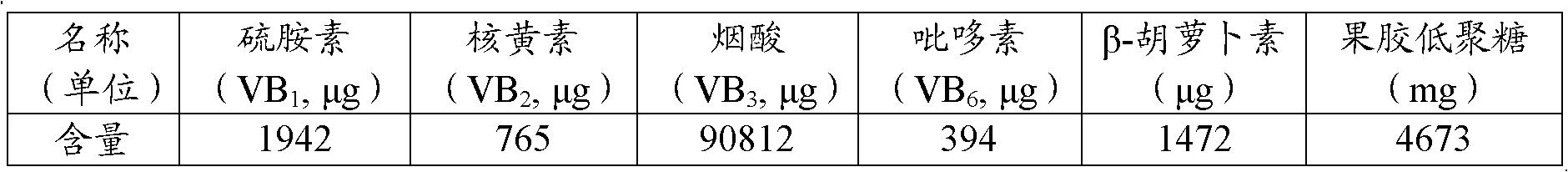

Embodiment 1

[0025] Preservation and expansion of yeast strains:

[0026] Slant preservation medium: 1 g of peptone, 1 g of yeast extract, 0.4 g of NaCl, 1 g of glucose, 2 g of agar, 100 mL of water, pH 6.5, sterilized at high temperature, and cooled to make a slant. Bacteria were inserted, cultured at a constant temperature of 30°C for 2 to 3 days, and the storage temperature was 4°C.

[0027] Primary seed medium: glucose 10g, peptone 1g, yeast extract 1g, MgSO 4 ·7H 2 O0.02g, KH 2 PO 4 0.02 g, water 100 mL, pH 5.0. Inoculate a ring of slanted strains, the culture temperature is 30°C, the shaker speed is 200r / min, and the culture time is 18h to obtain a first-class seed solution.

[0028] Secondary seed tank medium: glucose 10g, peptone 1g, yeast extract 1g, MgSO 4 ·H 2 O 0.02g, KH 2 PO 4 0.02 g, water 100 mL, pH 5.0. The first-grade seed solution was inserted at a volume ratio of 5%, the culture temperature was 30°C, the stirring speed was 200r / min, and the culture time was 24h...

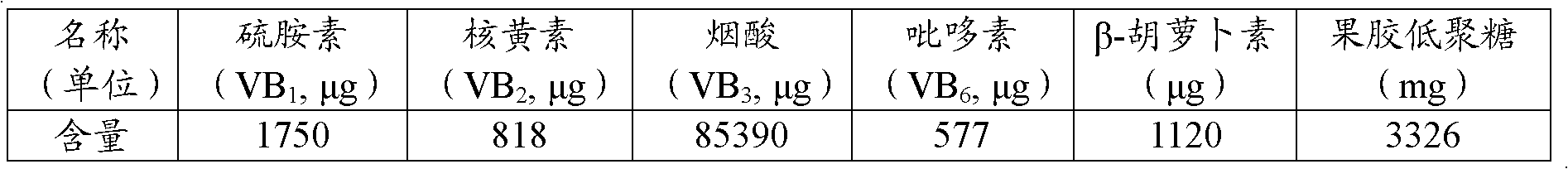

Embodiment 2

[0034] 1. Preparation of raw materials: Take ponkan picked in November in Quzhou area as raw material, weigh 150kg of raw materials after selection and classification, peel and directly beat the whole pulp to get 118.5kg of crude citrus pulp, take out 50kg for use.

[0035] 2. The first-stage enzyme treatment process: 50 kg of crude citrus pulp was continuously stirred, the pH was adjusted to 4.2 with sodium hydroxide, and the temperature was raised to 42°C. Food-grade acid pectinase and cellulase with strong specificity, good stability and enzymatic hydrolysis effect are mixed to prepare a compound enzyme preparation, and the mass ratio of cellulase and pectinase is 3:1. A total of 60 g of compound enzyme preparation was added to the crude citrus pulp, and the enzyme treatment time was 90 min. Acid pectinase: enzyme activity 30000u / g, purchased from Wuxi Xuemei Preparation Technology Co., Ltd.; cellulase: enzyme activity 40000u / g, purchased from Shandong Longda Bioengineering...

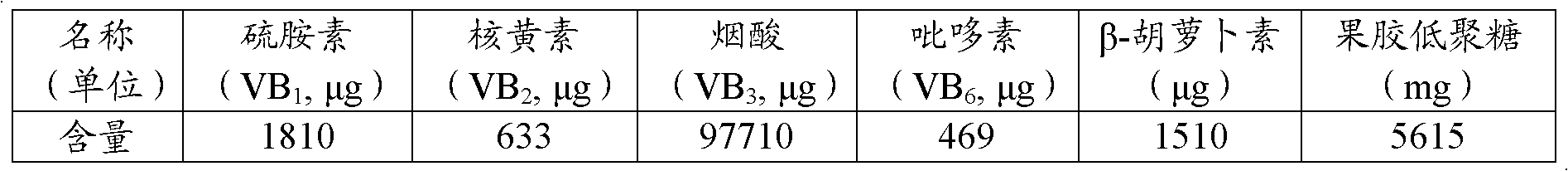

Embodiment 3

[0051] 1. Raw material preparation: The ponkan in Quzhou region of Example 2 was used as the raw material, 150 kg was selected, and the whole pulp was beaten after peeling to obtain 116.0 kg of crude citrus pulp, and 50 kg was taken out for use.

[0052] 2. The first-stage enzyme treatment process: 50 kg of crude citrus pulp was adjusted according to the steps of Example 2 to adjust the enzyme reaction conditions, and the compound enzyme preparation was added, and the ratio of cellulase to pectinase was 2:1. 70 g of compound enzyme preparation was added to the crude citrus pulp, and the enzyme treatment time was 90 min. Acid pectinase: enzyme activity 30000u / g, purchased from Wuxi Xuemei Preparation Technology Co., Ltd.; cellulase: enzyme activity 40000u / g, purchased from Shandong Longda Bioengineering Co., Ltd.

[0053] 3. According to the filtering process of Example 2, 42.1 kg of orange juice was obtained, and the juice yield was 84.2%. Comparative test: another 50kg of cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com