Method for preparing micro structural zinc oxide by hydrothermal method

A technology of micron structure and zinc oxide, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of harsh experimental conditions, high reaction temperature, poor repeatability, etc., and achieve the effect of simple method, high purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

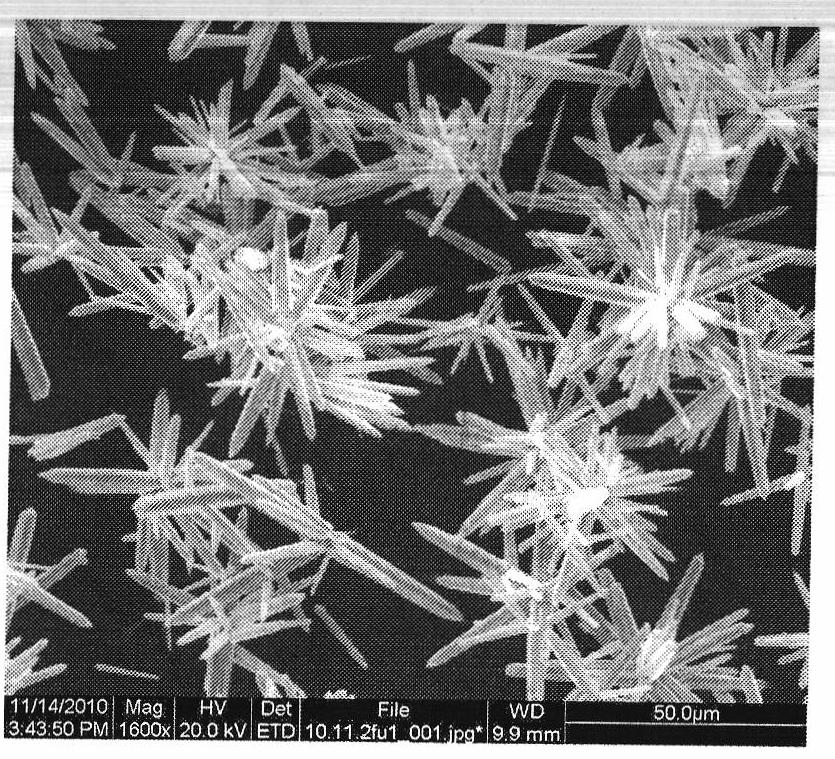

Embodiment 1

[0025] Taking the preparation of micron sea urchin-like zinc oxide material as an example, the specific preparation method is as follows:

[0026] The mass fraction is 30% H 2 O 2 Add 5g to 71g of distilled water, stir at room temperature for 5 minutes, add polyvinylpyrrolidone K-300.12g, stir at room temperature for 10 minutes, add 0.439g zinc acetate dihydrate, stir at room temperature for 20 minutes, add 4mL of substance with a concentration of 5mol / L NaOH aqueous solution, polyvinylpyrrolidone K-30 and zinc acetate dihydrate, 30% H 2 O 2 The mass ratio of distilled water and NaOH is 1:3.658:41.67:591.7:6.667. Stir at room temperature. After the solution becomes white turbid, continue to stir for 5 minutes. Pour the white turbid solution into a hydrothermal reactor lined with polytetrafluoroethylene In the middle, the hydrothermal reaction vessel was sealed, and the hydrothermal reaction vessel was placed in an oven at a temperature of 180°C for 24 hours, centrifuged, and the p...

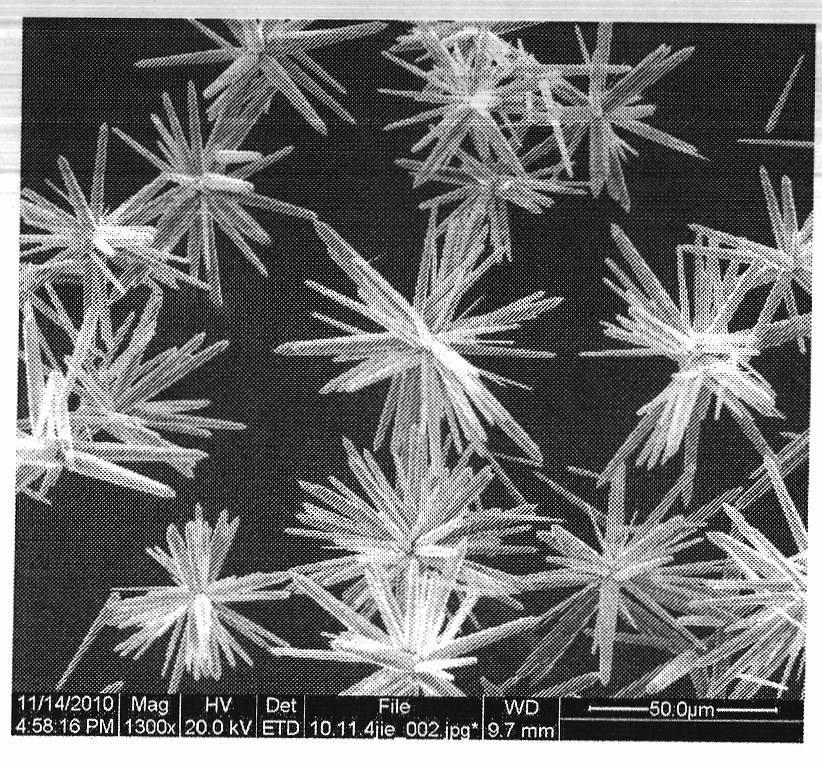

Embodiment 2

[0029] In Example 1, the H with a mass fraction of 30% 2 O 2 Add 1g to 56g distilled water, stir at room temperature for 5 minutes, add polyvinylpyrrolidone K-300.12g, stir at room temperature for 10 minutes, add 0.0439g zinc acetate dihydrate, stir at room temperature for 20 minutes, add 2mL of substance with a concentration of 5mol / L NaOH aqueous solution, polyvinylpyrrolidone K-30 and zinc acetate dihydrate, 30% H 2 O 2 The mass ratio of distilled water and NaOH is 1:0.3658:8.333:466.7:3.333, and the other steps are the same as in the corresponding examples to prepare micro-structured zinc oxide. The resulting product was characterized by Quanta 200 environmental scanning electron microscope, the results are shown in figure 2 .

[0030] by figure 2 It can be seen that the obtained product is micron sea urchin-like zinc oxide, and many zinc oxide micron rods grow from the center of the ball. The diameter of the sea urchin ball is 40-80 μm, the length of the rod is 20-40 μm, an...

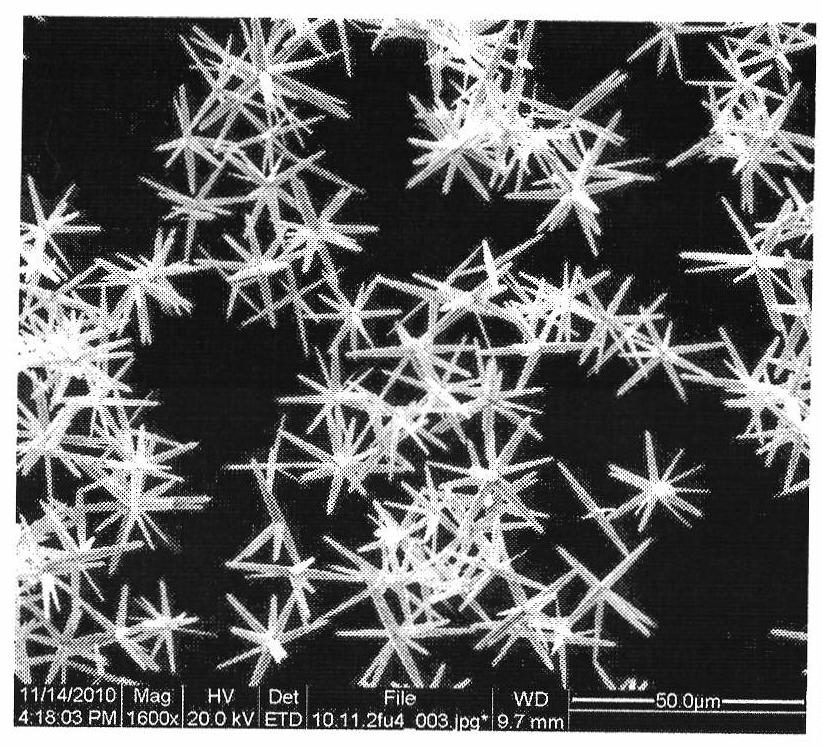

Embodiment 3

[0032] In Example 1, the H with a mass fraction of 30% 2 O 2 Add 16g to 60g distilled water, stir at room temperature for 5 minutes, add polyvinylpyrrolidone K-300.096g, stir at room temperature for 10 minutes, add 1.054g zinc acetate dihydrate, stir at room temperature for 20 minutes, add 12mL of substance with a concentration of 5mol / L NaOH aqueous solution, polyvinylpyrrolidone K-30 and zinc acetate dihydrate, 30% H 2 O 2 The mass ratio of distilled water and NaOH is 1:10.98:166.7:625:25, and the other steps are the same as in the corresponding examples to prepare micro-structured zinc oxide. The resulting product was characterized by Quanta 200 environmental scanning electron microscope, the results are shown in image 3 .

[0033] by image 3 It can be seen that the resulting product is micron sea urchin-like zinc oxide, and many zinc oxide micron rods grow from the center of the ball. The diameter of the sea urchin ball is 30-60 μm, the length of the rod is 15-30 μm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com