Ultrasonic probe

一种超声波、背衬构件的技术,应用在超声波探头领域,能够解决背衬层4变厚、成本增加、厚度困难等问题,达到灵敏度提高、减少反射波、强输出的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

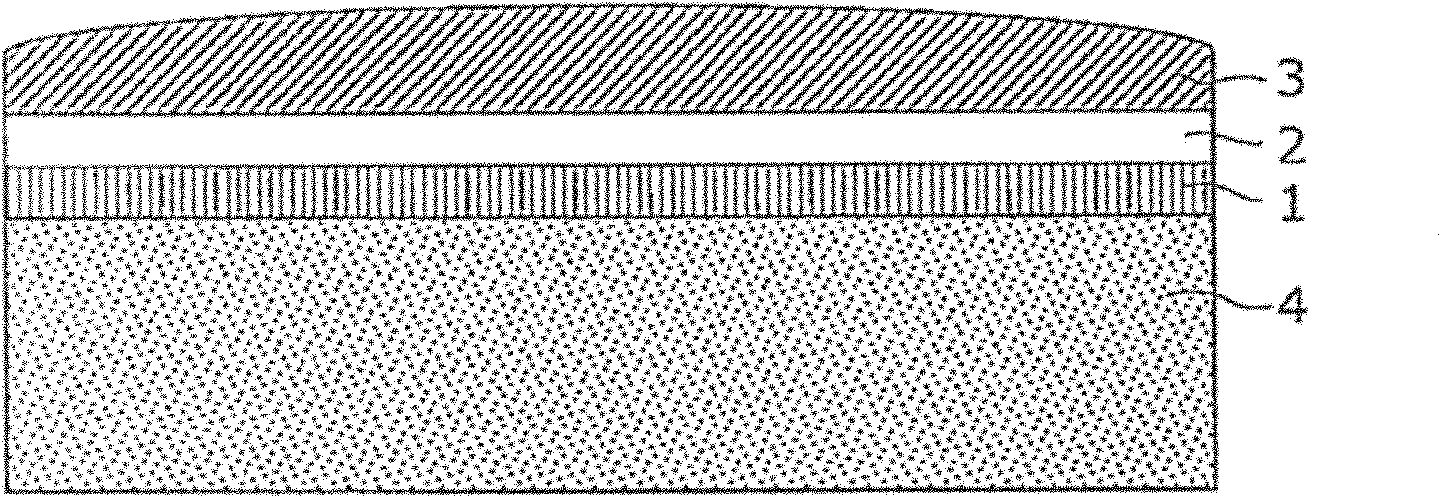

[0042] image 3 It is a cross-sectional view showing the ultrasonic probe in Embodiment 1 of the present invention. like image 3 As shown, the ultrasonic probe according to the first embodiment includes a piezoelectric vibrator 1 , a coupling layer 2 , an acoustic lens 3 , and a backing layer 4 .

[0043] like image 3 As shown, in the ultrasonic probe according to this embodiment, the acoustic tube 5 is arranged inside the backing layer 4 . The acoustic tube 5 has a width sufficiently smaller than the wavelength of the ultrasonic wave radiated from the piezoelectric vibrator 1 and is formed in such a length that the generation of the ultrasonic wave between the direct wave and the reflected wave cancels out.

[0044] For example, when the backing layer 4 is made of epoxy resin, if an ultrasonic wave of f=5 MHz is radiated from the piezoelectric vibrator 1 , the wavelength λ in the backing layer 4 can be obtained using Equation 1.

[0045] [Formula 1]

[0046] ...

Embodiment approach 2

[0050] Figure 4 It is a sectional view of the backing layer 4 in Embodiment 2 of this invention. A plurality of acoustic tubes 5 are disposed inside the backing layer 4 .

[0051] Figure 5It is a cross-sectional view showing an example of the arrangement of the acoustic tubes 5 in Embodiment 2, and in this figure, an example of the backing layer in which the acoustic tubes 5 are arranged based on the square remainder sequence is shown. The length Ln of each acoustic tube is determined by a one-dimensional square remainder sequence shown in Equation 2 below.

[0052] [Formula 2]

[0053] Ln = c · n 2 ( mod N ) 2 Nωr ...(Formula 2)

[0054] Here, c is the speed of sound, N is a prime number, n is an integer varying from 0 to (N-1), and ωr i...

Embodiment approach 3

[0064] In order to realize the backing layer 4 according to the third embodiment, based on the first embodiment, a 250 μm undulation is formed on the substrate by precision printing. Wherein, the length direction of the sound tube corresponds to the thickness direction of the printed ink. Figure 14A It is a flowchart showing the formation procedure of the backing layer by screen printing. Specifically, first, a mask for screen printing adjusted to obtain a dry thickness of 250 μm is formed on a substrate ( S1401 ). Next, a resist film for printing a predetermined pattern is formed (S1402), and a high-resistance material such as a conductive paste using metal is poured in as a paste to perform printing (S1403). Thus, pores are formed on the substrate. In addition, here, the thickness of the printed paste needs to be kept below 250 μm. By satisfying the above-mentioned conditions, the straightness of the sound wave relative to the pores is good, and a good effect can be obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com