Surface mounted device (SMD) type light emitting diode (LED) device for outdoor display screen and display module using SMD type LED device

A technology of LED devices and outdoor display screens, applied in the direction of electric solid-state devices, semiconductor devices, instruments, etc., can solve the problems of shortening the life of Top LED, cumbersome process procedures, and low production efficiency, so as to ensure high consistency and overcome uneven brightness , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

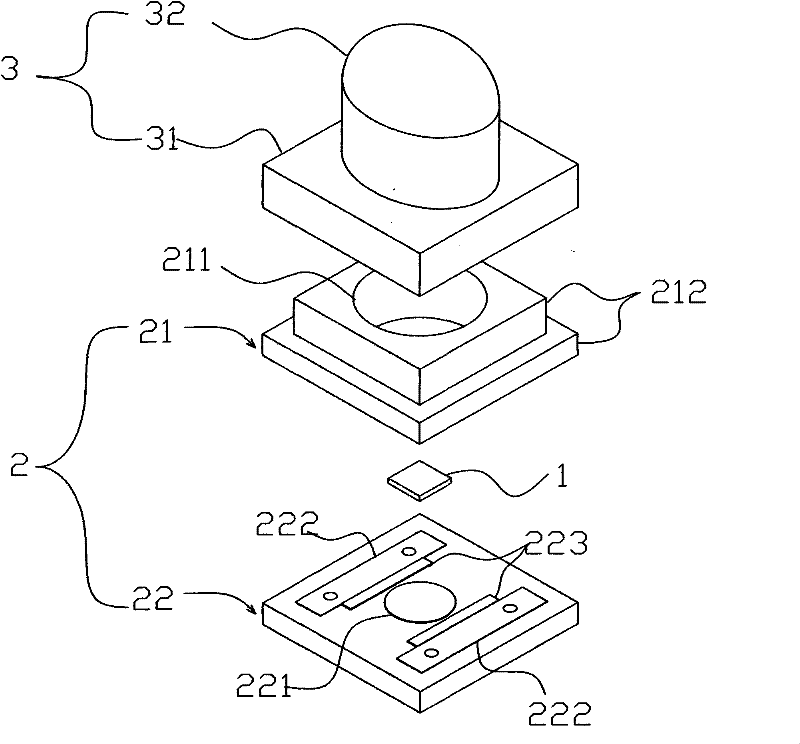

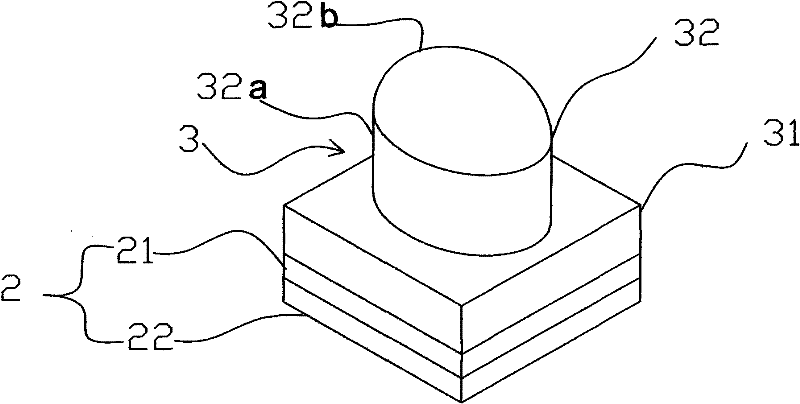

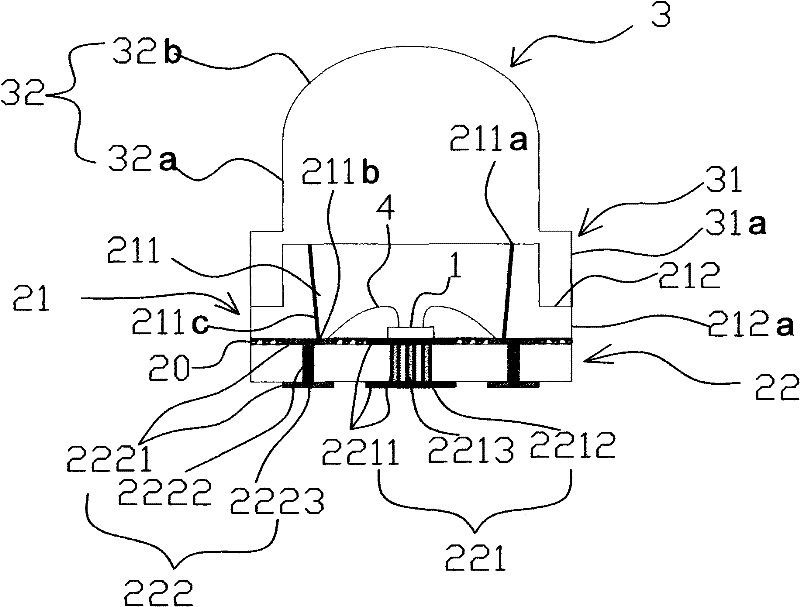

[0028] Figure 1a Shown is a three-dimensional exploded view of the SMD LED device for outdoor display screens according to the first embodiment of the present invention. see also Figure 1b and Figure 1c ,in, Figure 1b It is a perspective view of an SMD type LED device for an outdoor display screen according to the first embodiment of the present invention; Figure 1c for Figure 1b front cutaway view. The SMD type LED device for the outdoor display screen includes an LED chip 1 , a base 2 and an encapsulant 3 . Wherein, the base 2 includes a lower base 22 carrying the LED chip 1 and an upper base 21 combined with the lower base 22 . In an embodiment of the present invention, an adhesive 20 is passed between the upper base 21 and the lower base 22 (see Figure 1c ) combined.

[0029] In the embodiment of the present invention, there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com