Heatproof and anticorrosion rare earth magnesium alloy with high obdurability and preparation method thereof

A rare earth magnesium and heat-resistant technology, which is applied in the field of high-strength, heat-resistant and corrosion-resistant rare earth magnesium alloys, can solve the problems of restricting the use of alloys and reducing the corrosion resistance of alloys, so as to eliminate the reduction of mechanical properties, improve mechanical properties, and improve durability. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

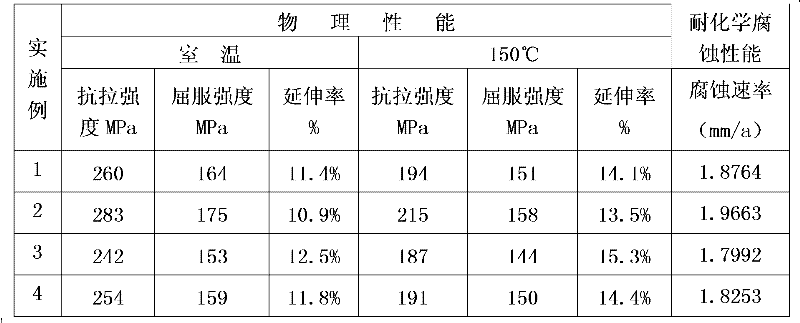

Embodiment 1

[0020] According to the proportion by weight, 5% of aluminum (Al), 0.4% of manganese (Mn), 0.8% of yttrium (Y), 0.3% of antimony (Sb), 0.8% of cadmium (Cd), and the rest are magnesium (Mg) Alloy materials are prepared. After the industrial pure magnesium is completely melted in the crucible under the flux or gas protection melting conditions, at 660 ° C, the industrial pure aluminum, aluminum manganese (Al-Mn) intermediate alloy and magnesium yttrium Add alloying elements in the form of (Mg-Y) master alloy. After the added charge is completely dissolved into alloy melt, the temperature is raised to 710°C, and then industrial pure antimony and industrial pure cadmium are pressed into the alloy melt from the bell jar. , stir and mix evenly and continue to heat up to 710°C, then add refining agent to refine the magnesium alloy liquid and refine for 10 minutes, and pour after standing for 20 minutes to obtain the high-strength, toughness, heat-resistant and heat-resistant alloy wit...

Embodiment 2

[0022]According to the proportion by weight, 5% of aluminum (Al), 0.1% of manganese (Mn), 2.5% of yttrium (Y), 1.0% of antimony (Sb), 0.5% of cadmium (Cd), and the rest are magnesium (Mg) Alloy materials are prepared. After the magnesium is completely melted in the crucible under the flux or gas protection melting conditions, at 650 ° C, industrial pure aluminum, aluminum manganese (Al-Mn) intermediate alloy and magnesium yttrium (Mg -Y) Alloying elements are added in the form of intermediate alloys. After the added charge is completely dissolved into an alloy melt, the temperature is raised to 690°C, and then industrial pure antimony and industrial pure cadmium are pressed into the alloy melt from the bell jar and stirred. Mix well and continue to heat up to 730°C, then add refining agent to refine the magnesium alloy solution for 5 minutes, and pour after standing for 10 minutes to obtain the high-strength, toughness, heat-resistant and corrosion-resistant rare earth with exc...

Embodiment 3

[0024] According to the proportion by weight, 3% of aluminum (Al), 0.4% of manganese (Mn), 0.8% of yttrium (Y), 0.3% of antimony (Sb), 0.3% of cadmium (Cd), and the rest are magnesium (Mg) Alloy materials are prepared. After the industrial pure magnesium is completely melted in the crucible under the flux or gas protection melting conditions, at 670 ° C, the industrial pure aluminum, aluminum manganese (Al-Mn) intermediate alloy and magnesium yttrium Add alloying elements in the form of (Mg-Y) master alloy. After the added charge is completely dissolved into alloy melt, the temperature is raised to 695°C, and then industrial pure antimony and industrial pure cadmium are pressed into the alloy melt from the bell jar. , stir and mix evenly and continue to heat up to 725 ° C, then add refining agent to refine the magnesium alloy solution for 15 minutes, and then pour it after standing for 15 minutes to obtain the high-strength, toughness, heat-resistant and heat-resistant alloy wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com