Low temperature pyrolysis method of solid fuel in counter flow downer pyrolysis reactor

A technology of pyrolysis reactor and solid fuel, which is applied in the direction of biofuel, direct heating dry distillation, special form dry distillation, etc. It can solve the problems of increasing the complexity of the overall process, difficulty in obtaining semi-coke products, and difficult separation, so as to reduce operation Complexity, extended residence time, effects of fully heated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

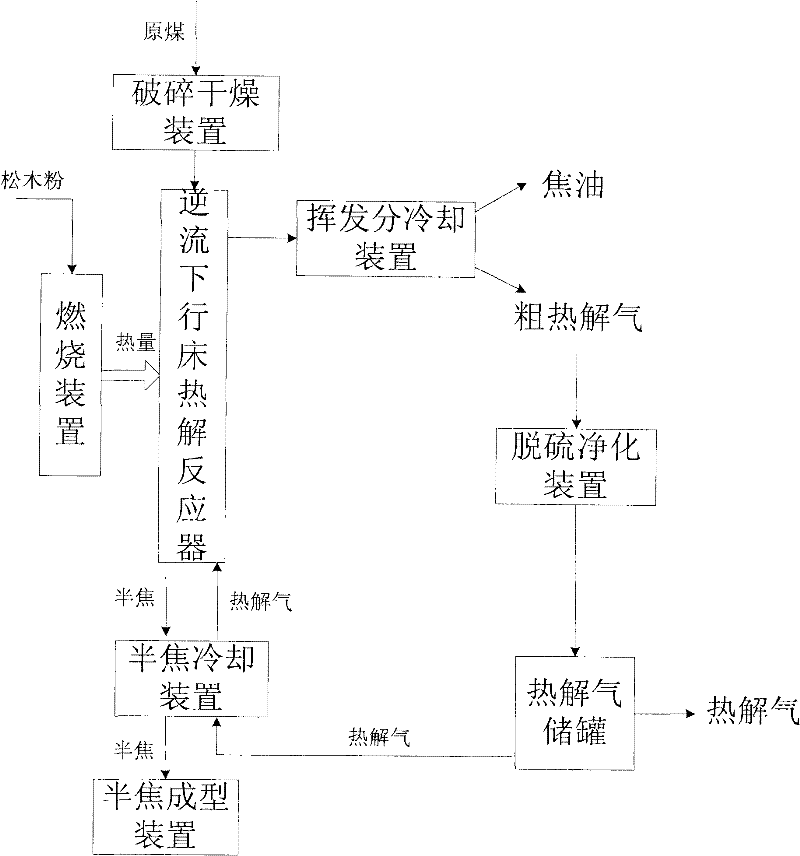

[0032] figure 2 Is the schematic diagram of the process flow of the present embodiment, by figure 2 It can be seen that the method for preparing clean semi-coke, tar, and high calorific value pyrolysis gas by low-temperature pyrolysis of coal in the countercurrent down-flow bed pyrolysis reactor of this embodiment is as follows:

[0033] Put the Huolinhe coal into the coal crushing and drying device, crush and dry it into coal with a diameter of less than 2mm, and after heating up to 120°C, send the coal from the top into the countercurrent descending bed pyrolysis reactor, and use pine wood powder as fuel in the combustion device The heat generated by combustion supplies the heat required for the coal pyrolysis reaction in the countercurrent down-flow bed pyrolysis reactor;

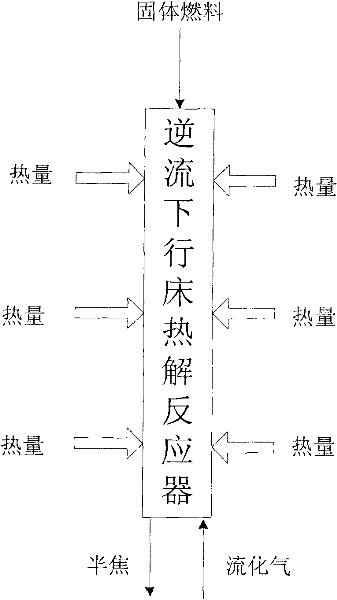

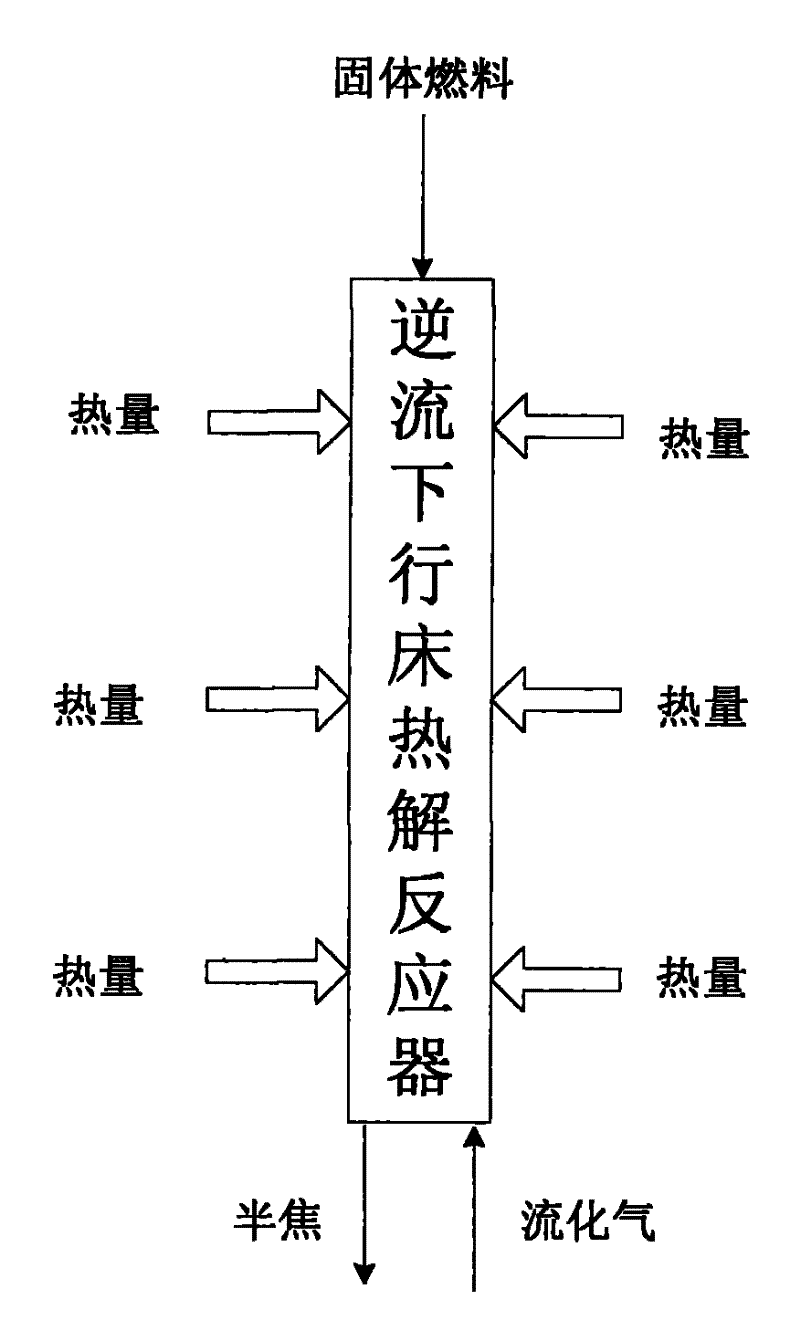

[0034]Coal is fed from the top of the counter-current down-bed pyrolysis reactor, passes through the counter-current down-bed pyrolysis reactor from top to bottom, and is in countercurrent contact wit...

Embodiment 2

[0037] In this embodiment, the same experimental pyrolysis coal solid fuel and experimental method as in Example 1 are adopted, the difference is that the fuel burned in the combustion device is coal, and the pyrolysis temperature is different;

[0038] In this example, the flue gas temperature in the combustion device is controlled at 900°C, the temperature of the semi-coke at the bottom of the countercurrent descending bed pyrolysis reactor is 690°C, and the temperature of the volatile matter outlet at the top of the countercurrent descending bed pyrolysis reactor is 590°C. The semi-coke is obtained in this example The yield is 64wt% of the weight of the coal raw material, the yield of tar is 14wt% of the weight of the coal raw material, and the yield of pyrolysis gas is 10wt% of the weight of the coal raw material.

Embodiment 3

[0040] In this embodiment, the same experimental pyrolysis coal solid fuel and experimental method as in Example 1 are adopted, the difference is that the fuel burned in the combustion device is gas, and the pyrolysis temperature is different;

[0041] In this example, the flue gas temperature in the combustion device is controlled to be 1000°C, the temperature of the semi-coke at the bottom of the countercurrent descending bed pyrolysis reactor is 780°C, and the temperature of the volatile matter outlet at the top of the countercurrent descending bed pyrolysis reactor is 680°C. The yield is 62wt% of the weight of the coal raw material, the yield of tar is 11wt% of the weight of the coal raw material, and the yield of pyrolysis gas is 15wt% of the weight of the coal raw material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com