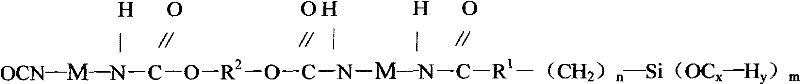

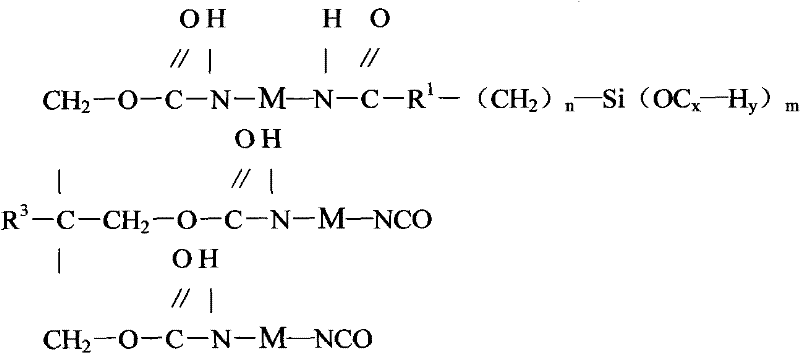

Diisocyanate prepolymer as curing agent and preparation method thereof

A technology of diisocyanate and isocyanate group is applied in the field of silane coupling agent modified diisocyanate prepolymer curing agent and its preparation, which can solve the problems of easy yellowing, aging, dependence on imports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 (by method 1)

[0051] a. Add 200 grams of molten 4,4'-MDI and 60 grams of ethyl acetate into the reaction kettle, heat up to 65°C to dissolve and stir well, cool down to 35°C, add 42 grams of γ-mercaptopropyltrimethoxy Silane, react at 35-50°C for 2 hours, 50-70°C for 1 hour, and 70-80°C for 1 hour; b. Cool down to 45°C, add 9.5 grams of dehydrated 3-methyl-1,5-pentane Diol, react at 50-60°C for 2 hours, and react at 70-80°C for 2 hours; c. Cool down to 50°C, add dropwise a mixture of 18.9 grams of trimethylolpropane and 20 grams of ethyl acetate, drop for 1.5 hours Complete, react at 50-60°C for 2 hours, react at 70-80°C for 1 hour, react at 80-90°C for 1 hour, and cool down to 60°C; d, add 11 grams of butyl acetate and stir well to obtain 361 grams of solid content of 75% functional MDI curing agent with a viscosity of 4200mpa.s (25°C). The NCO content of the curing agent was detected to be 9% (12% based on total solids).

[0052] Note: 1. The detecti...

Embodiment 2

[0055] Embodiment 2 (by method 1)

[0056] a, add 200 grams of MDI-50 (that is, 4,2'-MDI weight is 50%, 4,4'-MDI weight is 50% mixture) and 40 grams of ethyl acetate in the reaction kettle, heat up to 60 ℃ Melt and stir evenly, cool down to 40°C, add 33 grams of γ-mercaptopropyltriethoxysilane, react at 40-50°C for 1 hour, 50-60°C for 2.5 hours, and 70-80°C for 1 hour; b , cool down to 45°C, add a mixed solution composed of 4 grams of neopentyl glycol and 5 grams of dipropylene glycol through dehydration, react at 50-60°C for 2 hours, and react at 70-80°C for 2 hours; c, cool down to 50°C , add a mixture of 22 grams of trimethylolpropane and 22 grams of ethyl acetate three times, react at 50-60°C for 2 hours, 70-80°C for 3 hours, 80-90°C for 1 hour, and cool down to 60 ℃; d, add 10 grams of butyl acetate and 16 grams of toluene, and stir evenly to obtain 352 grams of functional MDI curing agent with a solid content of 75% and a viscosity of 3500mpa.s (25°C).

Embodiment 3

[0057] Embodiment 3 (by method 1)

[0058] a. Add 200 grams of IPDI liquid and 40 grams of ethyl acetate into the reaction kettle, heat up to 60°C and stir evenly, cool down to 40°C, add 8 grams of γ-mercaptopropyltrimethoxysilane, and then add 0.1 grams of dilauric acid Dibutyltin, react at 40-50°C for 2 hours, 60-70°C for 1 hour, and 70-80°C for 1 hour; b, cool down to 50°C, add 13 grams of dehydrated ethyl hexanediol in two times, React at 50-60°C for 2 hours, 70-80°C for 1 hour, and 80-90°C for 1 hour; c. Cool down to 50°C, and add 26 grams of trimethylolethane and 30 grams of ethyl acetate three times to form The mixed solution was reacted at 50-60°C for 2 hours, at 70-80°C for 2.5 hours, at 80-90°C for 0.5 hours, and cooled to 60°C; d, adding 12 grams of propylene glycol monomethyl ether acetate, stirring evenly to obtain 329 grams of solid content is 75% and the viscosity is 3900mpa.s (25 ℃) functional type IPDI curing agent. The NCO content of the curing agent was de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com