Pipeline machine

A pipeline machine and breathing tube technology, applied in the field of pipeline machines, can solve problems such as wasting drinking water, temperature rise, and wasting energy, and achieve the effects of easy guarantee of sealing, reduction of manufacturing costs, and improvement of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

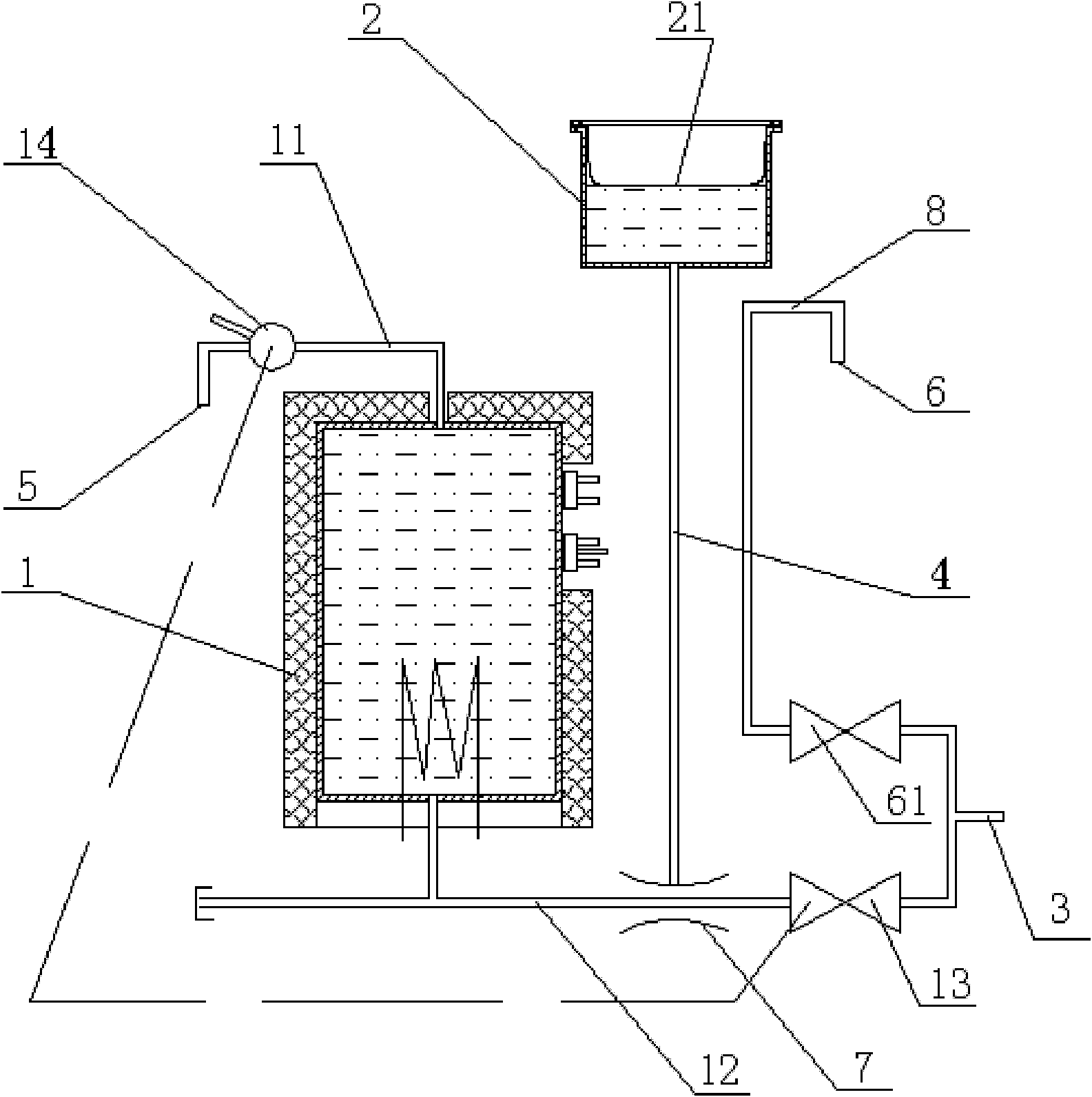

[0039] See figure 1 , This embodiment includes a hot tank 1, a regulated water reservoir 2, a pressure water source pipe 3, a breathing pipe 4, a hot water outlet 5, a normal temperature water outlet 6 and a throttling device 7.

[0040] The regulating water reservoir 2 is a water storage tank, and the water storage tank is provided with a diaphragm 21 for isolating the atmosphere, and the diaphragm 21 is fixed on the water storage tank by a fixing ring. The position of the regulating water storage 2 is higher than that of the hot tank 1 , and the top of the hot tank 1 is provided with a water outlet pipe 11 communicating with the hot water outlet 5 . The water inlet at the bottom of the hot tank 1 is communicated with a hot tank water inlet valve 13 through a hot tank water inlet pipe 12 . A hot water outlet valve 14 is connected between the water outlet pipe 11 of the hot tank 1 and the hot water outlet 5; the hot water outlet valve 14 is linked with the hot water inlet val...

Embodiment 2

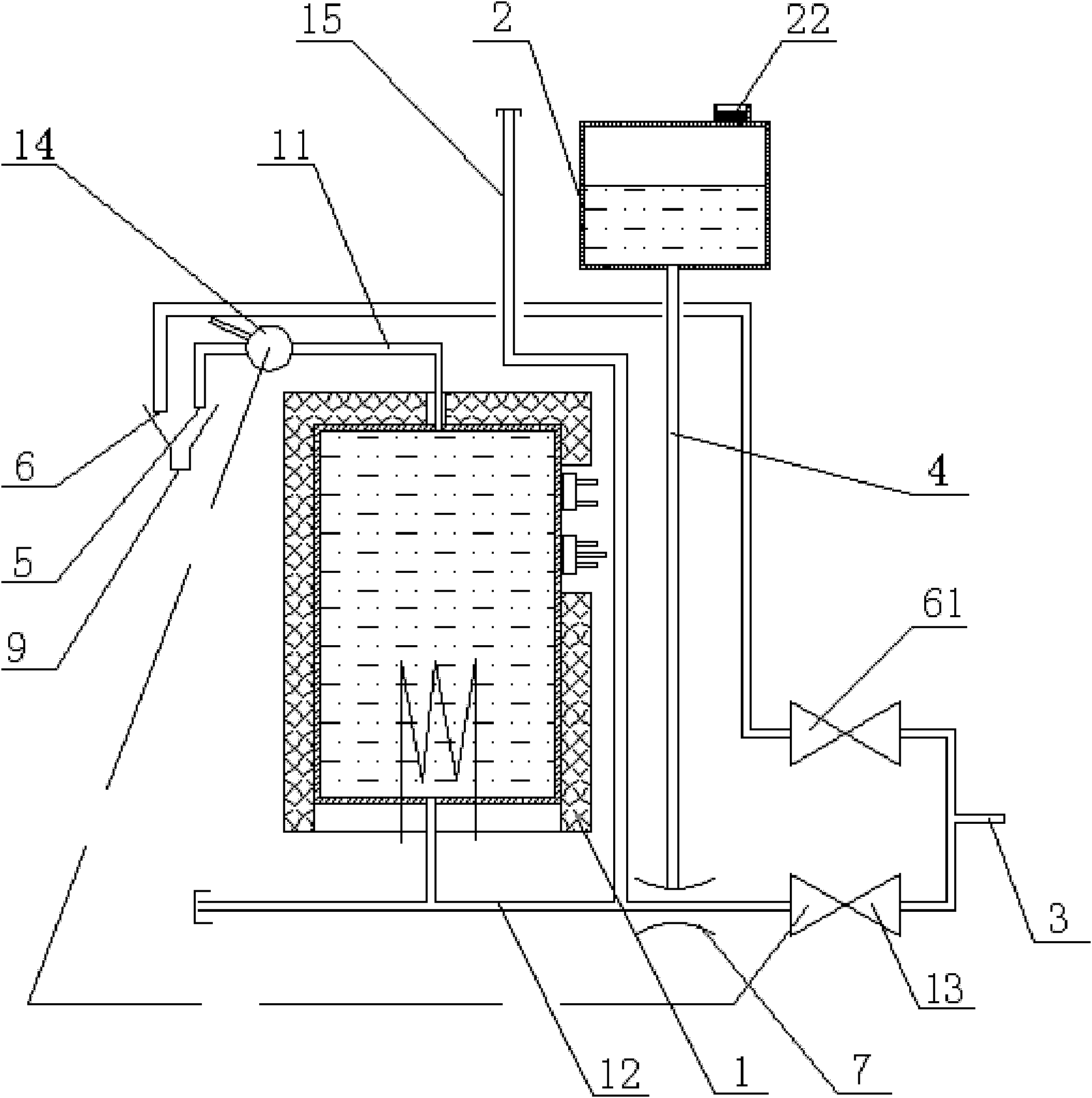

[0047] See image 3 , This embodiment is basically the same as Embodiment 1, except that it also includes a main water outlet 9, and the hot water outlet 5 and the normal temperature water outlet 6 are connected to the main water outlet 9. In addition, the water storage tank is provided with a breathing hole 22 capable of preventing dust from entering the regulating water tank, and the water inlet pipe 12 of the hot tank is connected with a liquid feeding pipe 15 .

Embodiment 3

[0049] See Figure 4 , This embodiment is basically the same as Embodiment 2, the difference is that the water storage bag 2 is a water storage bag, and a pressure device 8 capable of applying pressure to the water bag is arranged above the water storage bag. The pressing device 8 includes a pressing block 81 arranged above the water storage bag and a spring 82 arranged above the pressing block 81 .

[0050] When the user takes hot water, under the spring pressure, the water in the regulating water storage 2 is forcibly pressed into the hot tank 1, so that the regulating water storage 2 has sufficient capacity in the subsequent heating process of the hot tank 1 To accommodate the amount of water produced by the expansion of water in the hot tank 1. When the water source pressure is very low and the hot water outlet of the pipeline machine is higher than the regulating water storage 2, the effect of the pressure applying device 8 is particularly important.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com