Multi-stage depressed collector with lining grid and manufacturing method and application thereof

A collector and grid technology, which is applied in the collectors of transit-time electron tubes, the manufacture of non-light-emitting electrodes, and electron tubes with velocity/density modulation electron flow, etc., to achieve the effect of improving efficiency and suppressing emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention proposes an electrode structure in which a metal mesh is lined inside the metal electrode. Because for the same material, the secondary electron emission coefficient of the rough surface is smaller than that of the smooth surface. In the present invention, a layer of flat metal grid is attached to the inner surface of the electrode of the smooth multi-stage step-down collector. roughness, which can effectively reduce the secondary electron emission coefficient.

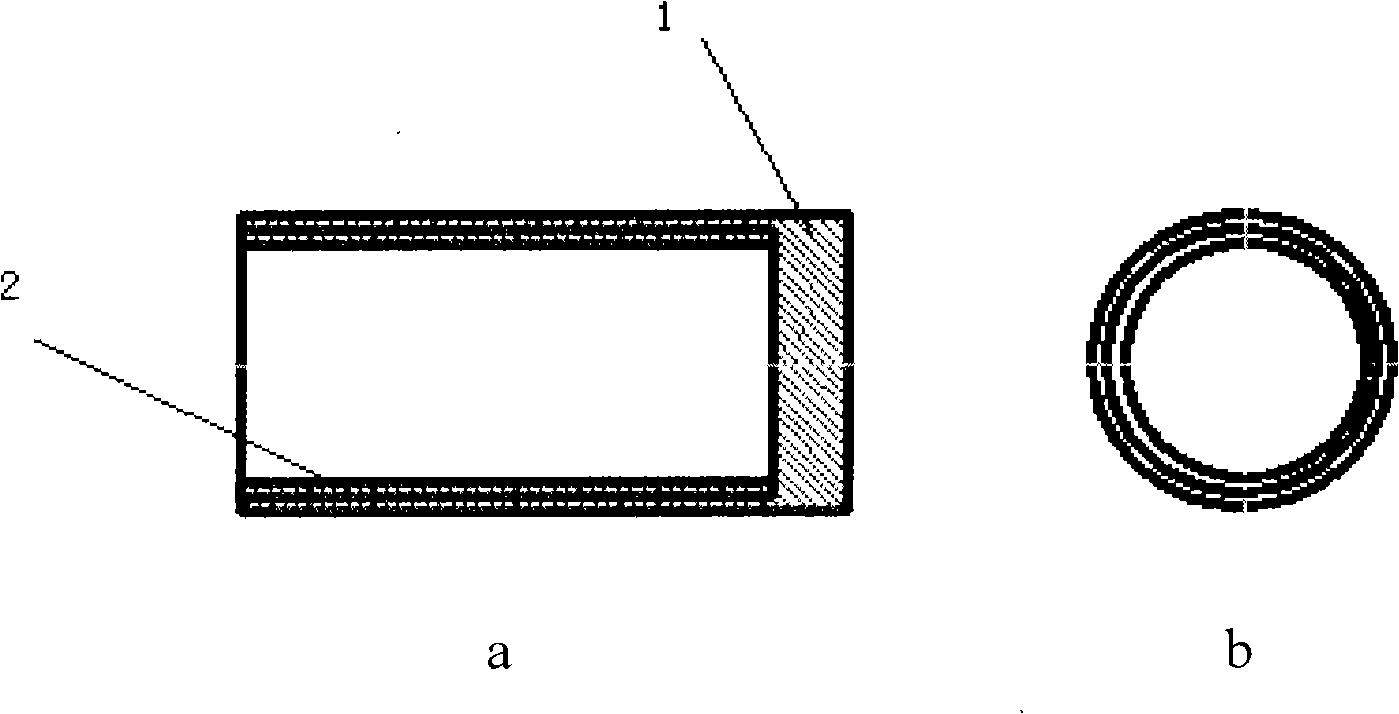

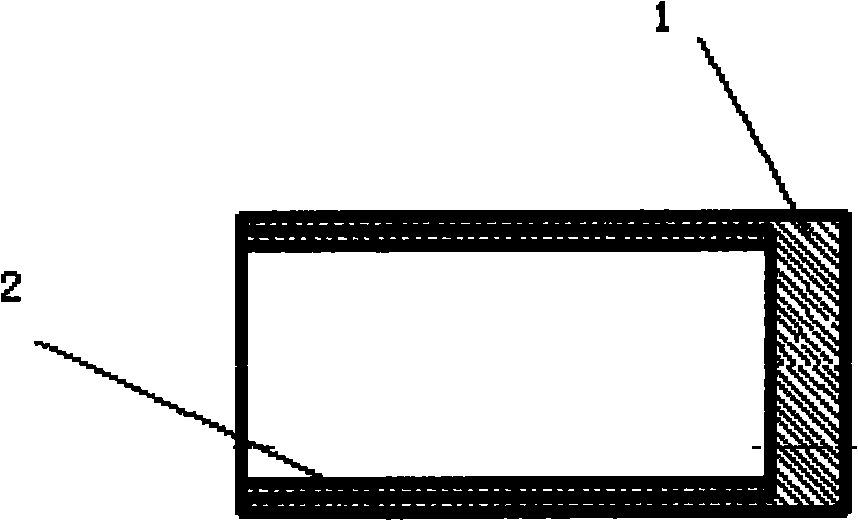

[0034] The main technical solution of the invention is to line the inner surface of the multi-stage pressure-reducing collector with a metal grid to suppress the emission of secondary electrons. Such as figure 1 As shown, the inner surface of the known multi-stage decompression collector 1 is lined with a metal grid 2 .

[0035] The specific method of the present invention lining metal grid on the inner surface of the multi-stage step-down collector is:

[0036] Purchase nickel, molybdenum, tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesh density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com