Method for preparing composition containing indium alcoholate and tin alcoholate and composition containing indium alcoholate and tin alcoholate prepared thereby

A manufacturing method and composition technology are applied in the field of compositions containing indium alkoxide and tin alkoxide, which can solve the problems of inconvenience, general methods and products do not have suitable methods and structures, and achieve the effect of low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

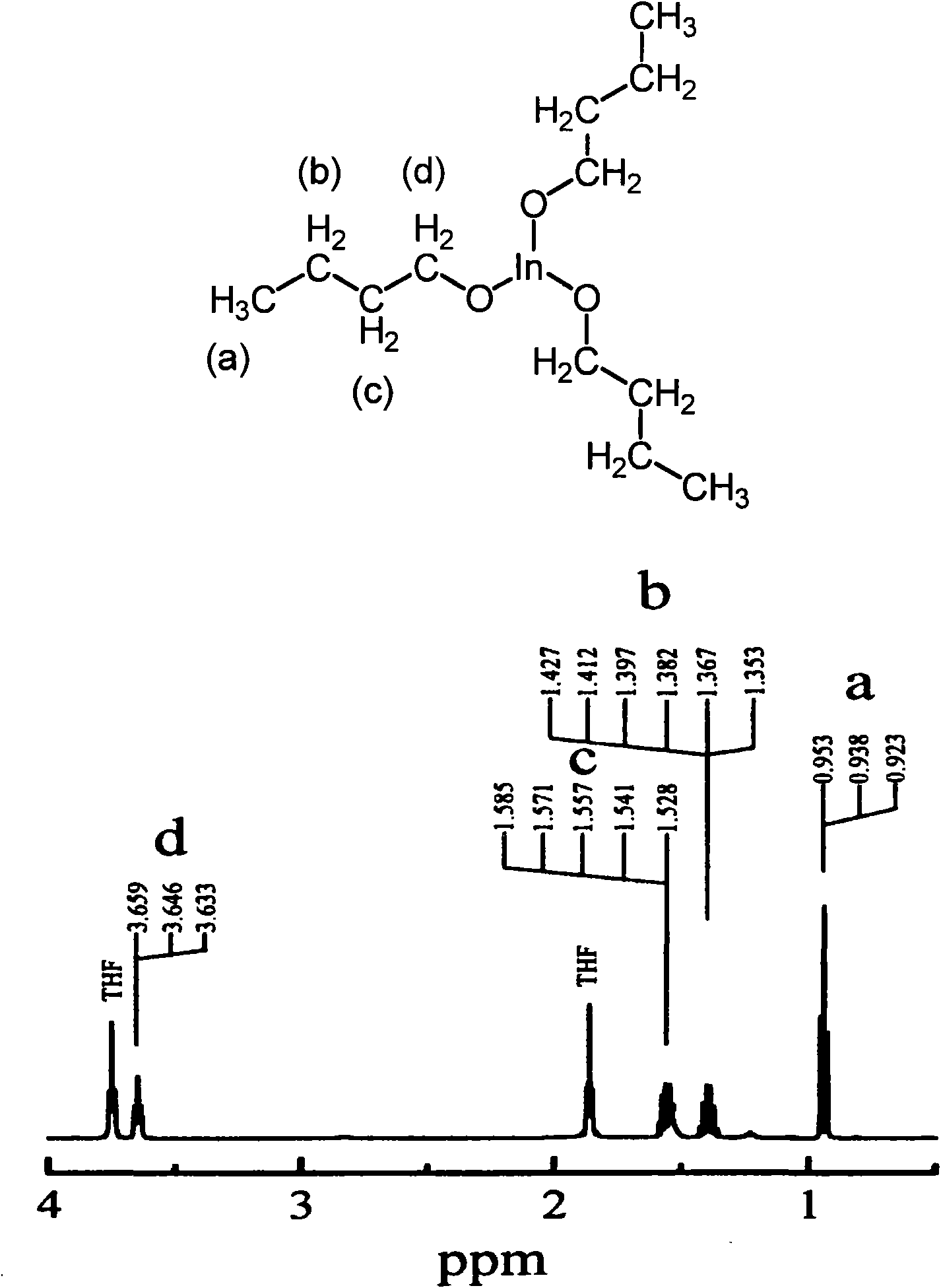

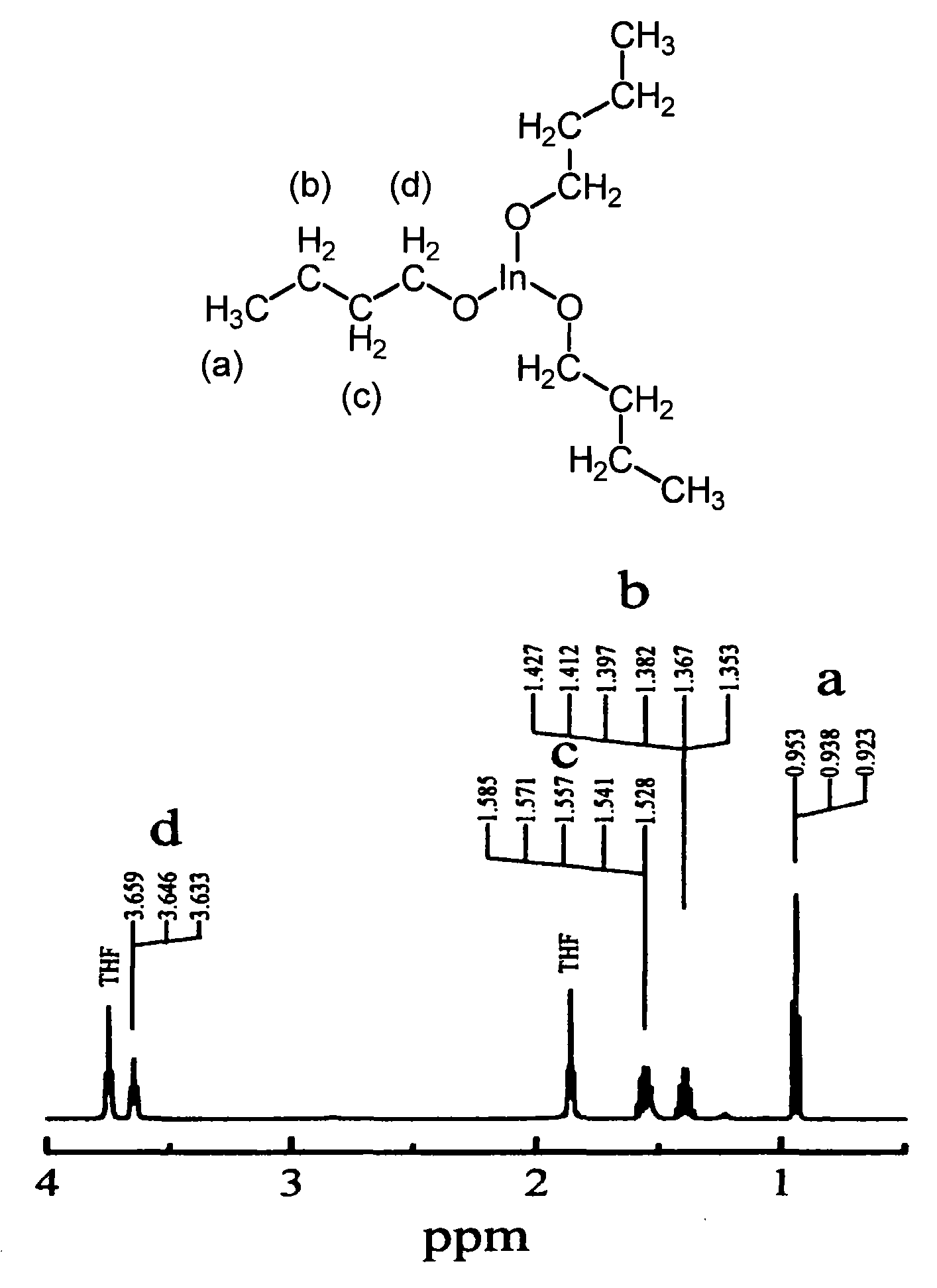

[0061] (1) Preparation of compositions containing indium alkoxide and tin alkoxide

[0062] (1), take anhydrous grade InCl 3 (0.885g, 0.004mole) was dissolved in 1.18g (0.016mole) 1-butanol (1-butanol) and 20ml (17.76g) THF mixed solvent and obtained colorless solution A after uniform stirring at room temperature; Water grade SnCl 4 (0.16g, 0.00044mole) was dissolved in 1-butanol (0.13g, 0.0017mole) and stirred uniformly at room temperature to obtain a colorless solution B; solution B was dropped into solution A dropwise, and at room temperature After being stirred under low pressure, it becomes transparent and colorless, and then the reaction temperature is set at 5° C. and reacted for 0.5 hours to obtain a first solution containing an indium alkoxide precursor and a tin alkoxide precursor.

[0063] (2), use the drop-by-drop method to dilute the diluted triethylamine solution [containing 0.5ml (0.405g, 0.00547mole) 1-butanol, 4.5ml (4g) THF and 1.4g (0.0139mole) Triethylam...

Embodiment 2

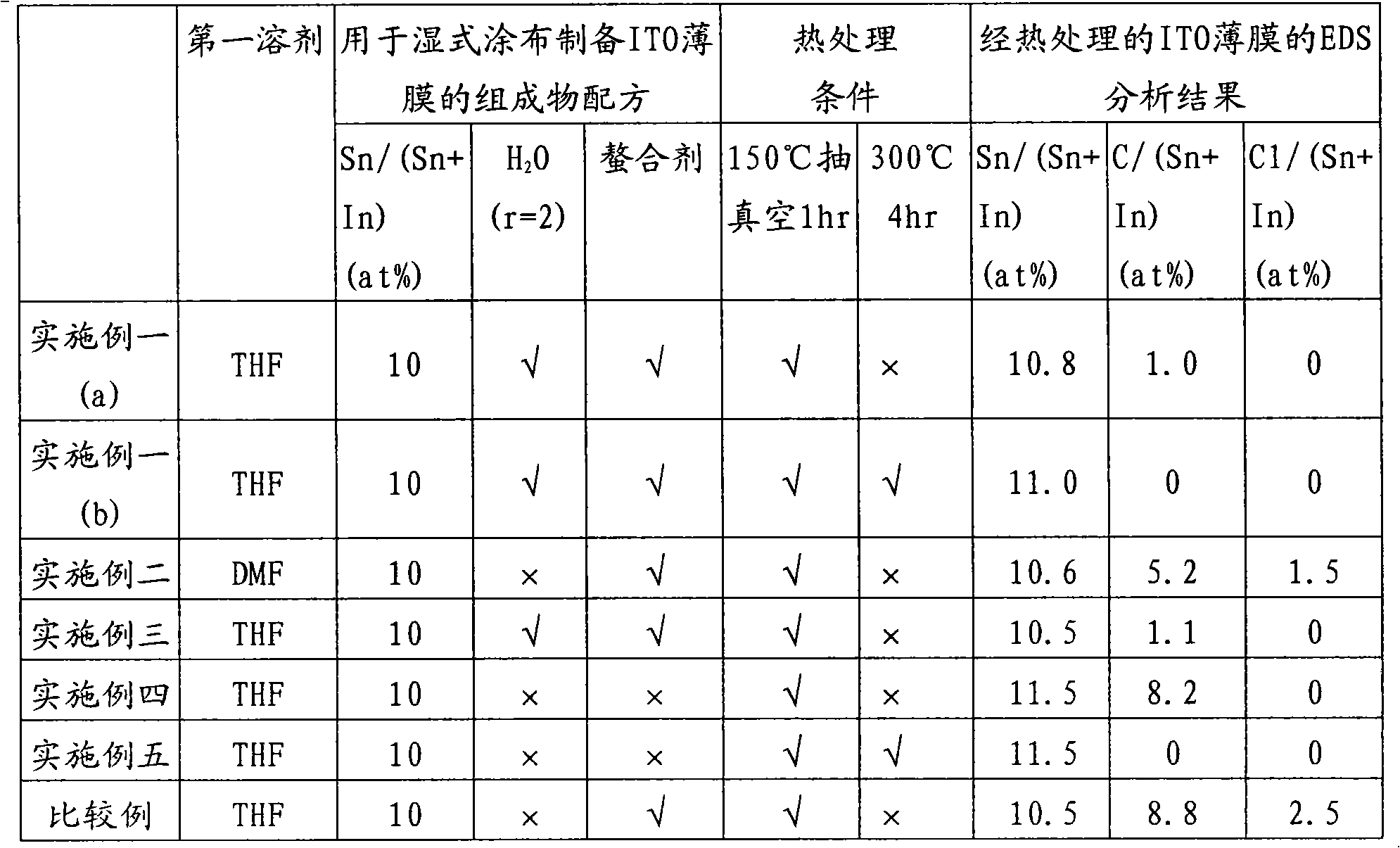

[0096] The formulation and composition preparation process of this example are the same as in Example 1, and the preparation of the ITO thin film is the same as that of the ITO-glass substrate sample in Example 1, except that THF as the first solvent is changed to DMF, and In the preparation of ITO films, no water was added before wet coating. The heat-treated ITO film prepared in this example is analyzed by EDS, and the result is: the ITO film produced in this example still contains a small amount of chlorine-containing substances, that is, InCl 3 and SnCl 4 Reaction may be incomplete, or HCl.NR 3 Salts or resulting complexes cannot be completely precipitated from DMF (Cl / (In+Sn)=1.5at%); and a small amount of carbon-containing organic substances (C / (In+Sn)=5.2at%); Sn / (Sn+In)=10.6at%.

Embodiment 3

[0098] The formulation and composition preparation process of this embodiment are the same as in Example 1, and the preparation of ITO thin film is the same as that of the ITO-glass substrate sample in Example 1, except that the amount of solvent THF in step (1) is changed from 20ml ( 17.76g) into 11ml (8.8g), and in step (3) only add the chelating agent of 0.4g (0.004mole) and do not add 1-butanol. The heat-treated ITO thin film that the present embodiment makes is analyzed by EDS, and the result is: do not contain the substance of chlorine, but contain very small amount of organic substance (C / (In+Sn)=1.1at%); Sn / (Sn+ In) = 10.5 at%. The surface resistivity of the sample obtained by further annealing the heat-treated ITO film varies depending on the temperature treatment conditions, and the results are similar to those in Example 1. In each step in this embodiment, the proportioning of various substances is different from that of Embodiment 1:

[0099] step 1):

[0100] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com