Precision forging process production line for steel rail turnout

A production line and track technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of long rail processing cycle, inaccurate rail positioning, time-consuming and labor-intensive problems, and achieve simple structure and good real-time performance , delivering precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

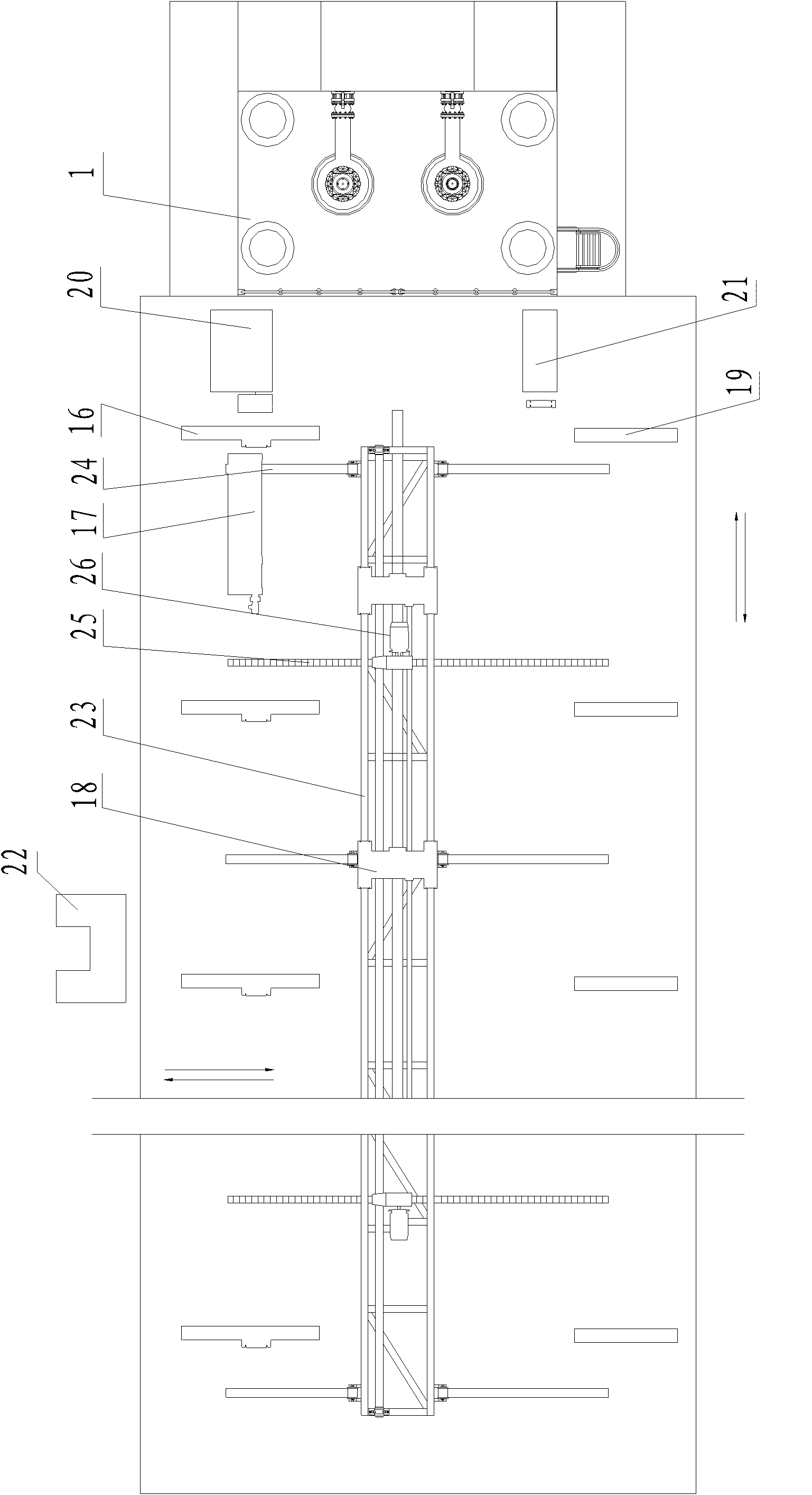

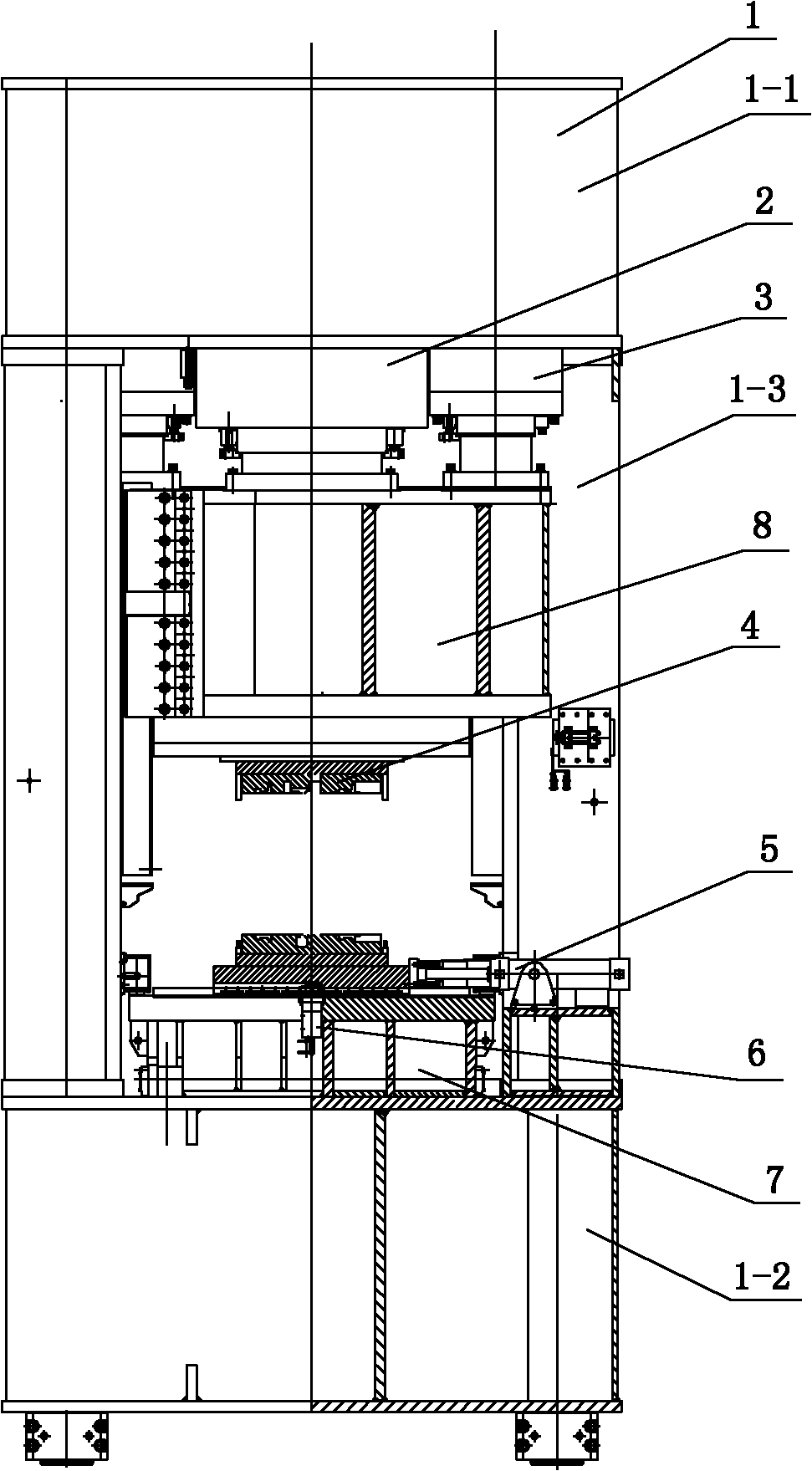

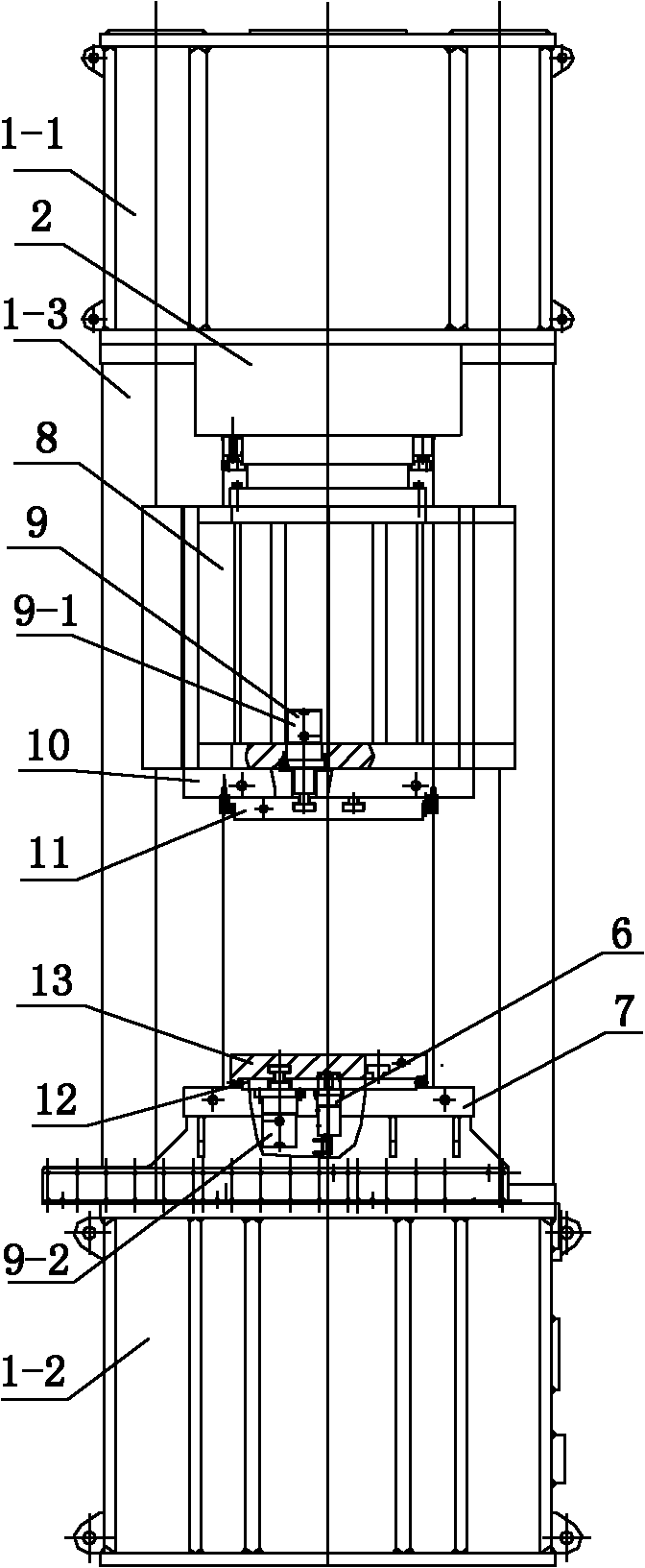

[0044] see figure 1 , steel rail fork precision forging production line, including steel track fork precision forging press 1, an intermediate frequency heating furnace 20 and a normalizing furnace 21 arranged in front of the precision forging press, and a rail forwarding device adjacent to the intermediate frequency heating furnace 20 for clamping the rail 17. A plurality of rail automatic feeding mechanisms arranged side by side on the same side as the heating furnace are used to push the rails into the heating furnace for heating. 16. An automatic rail unloading mechanism 19 on the same side as the normalizing furnace. 16 and the rail automatic unloading mechanism 19 are provided with a rail horizontal conveying trolley 23, and a lateral m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com