Gas diffusion layer and preparation method and application thereof

A gas diffusion layer and dispersant technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as difficult water discharge, catalyst penetration, and increased diffusion resistance of reaction gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

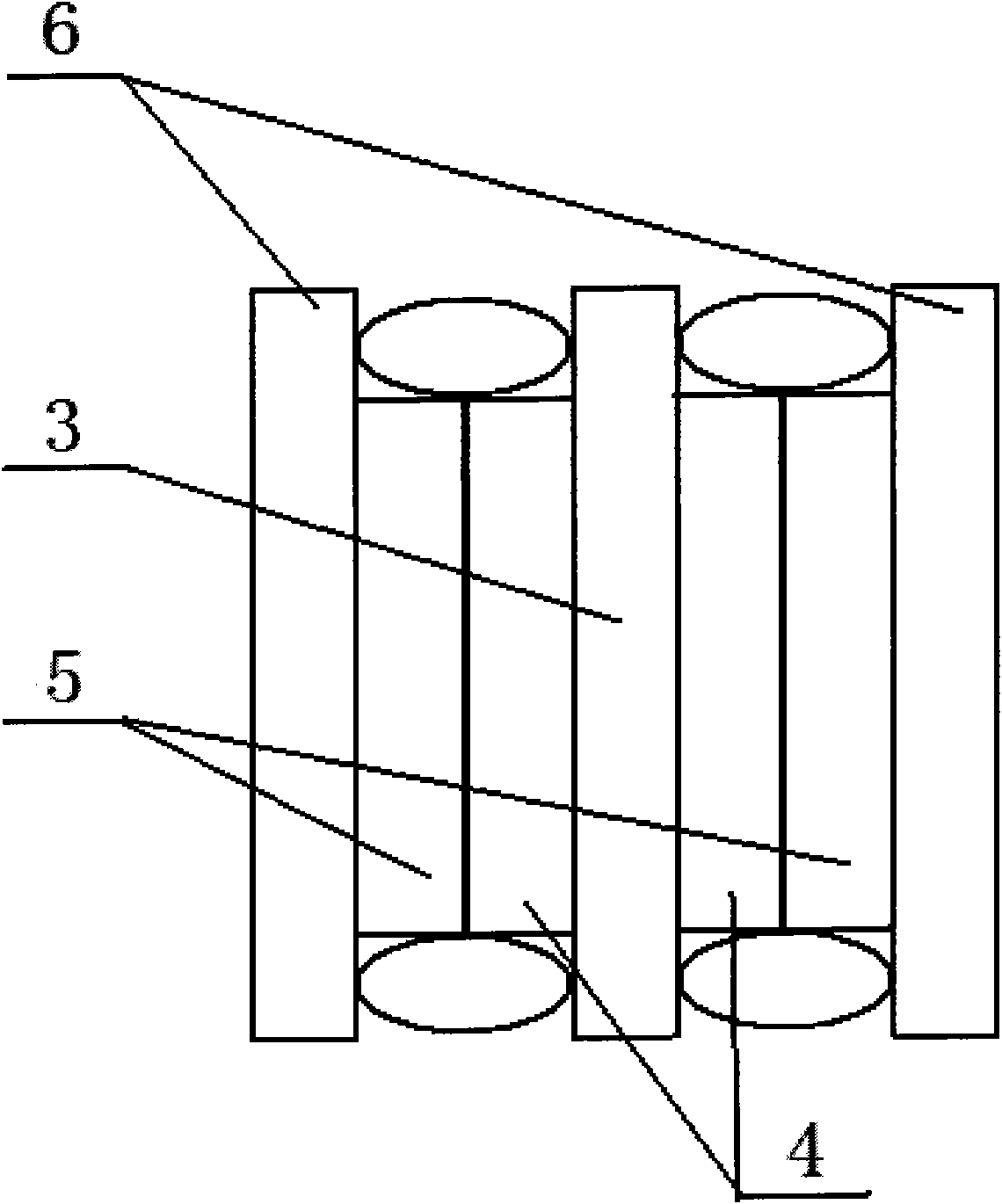

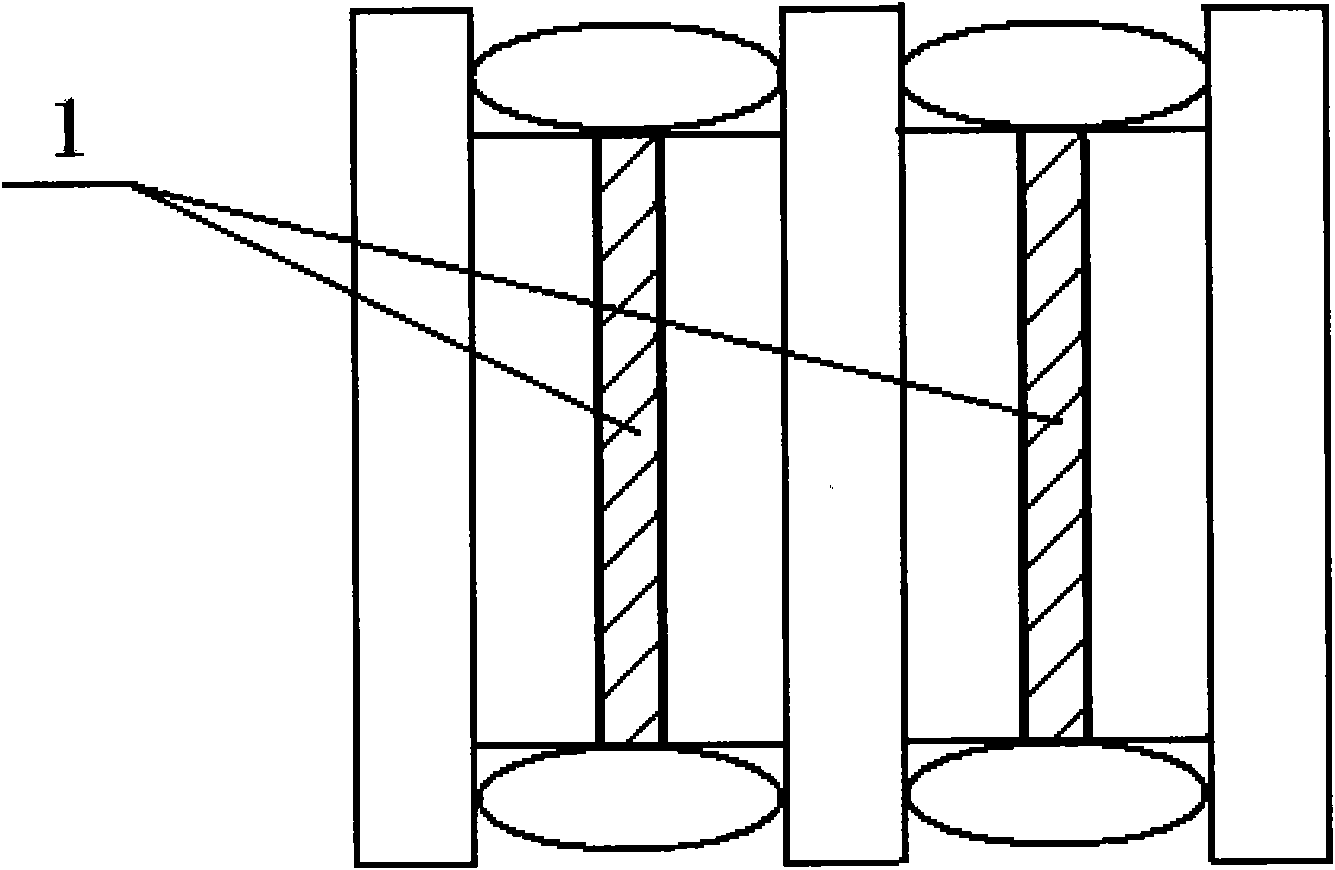

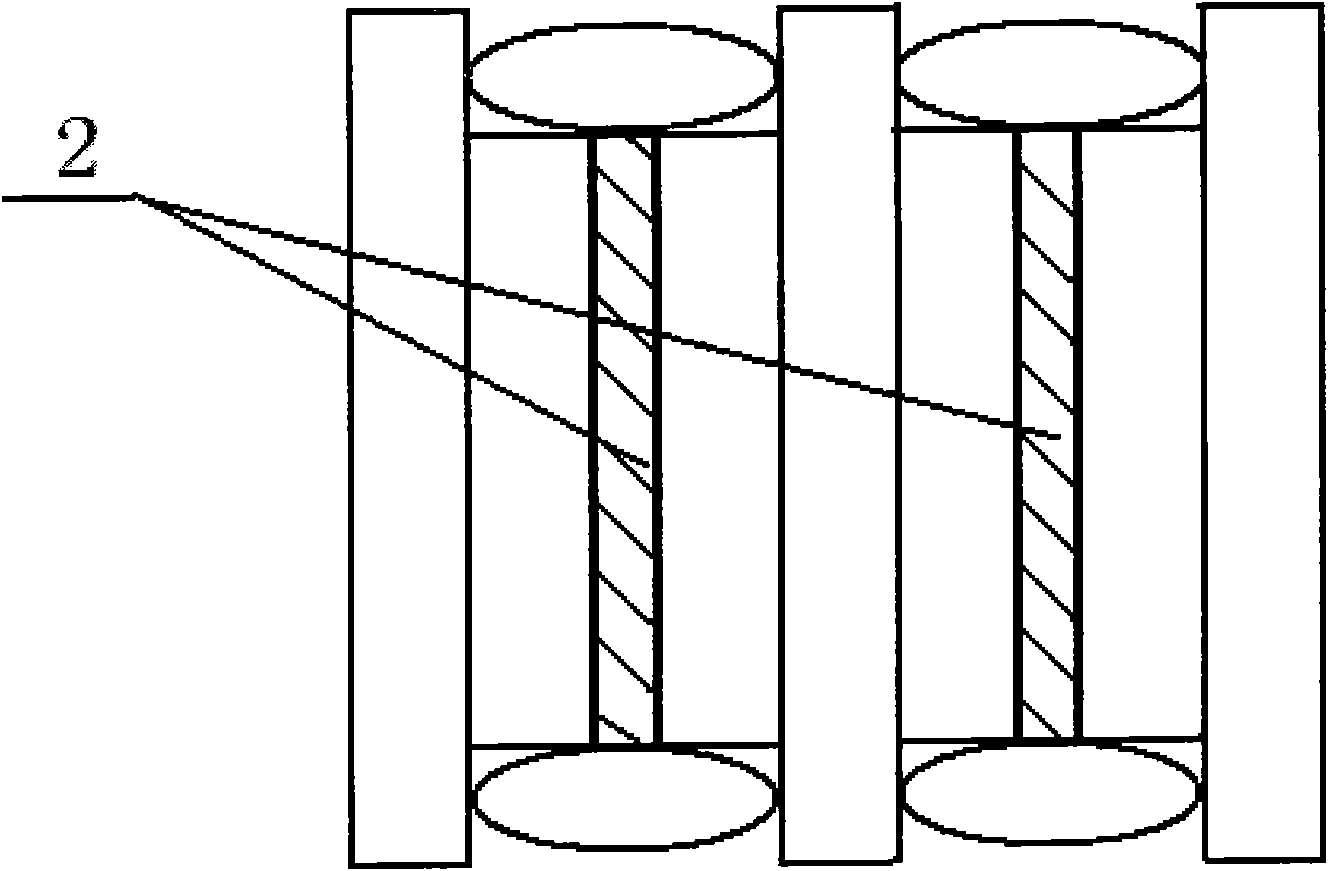

Image

Examples

preparation example Construction

[0046] Simultaneously, another technical scheme adopted by the present invention is: a kind of preparation method of gas diffusion layer, and its preparation steps are as follows:

[0047] 1) The carbon fiber material, dispersant and deionized water are configured into a uniform slurry, wherein the consumption of each component is: the carbon fiber material is 5-30wt% of the slurry, and the dispersant is 5-30wt% of the carbon fiber material; Add PTFE emulsion to the material and stir for 0.5-2 hours, wherein the amount of PTFE emulsion is 1050wt% of the carbon fiber material; then add a viscosity modifier to adjust the viscosity of the slurry to 1000-30000cps to obtain the carbon fiber slurry;

[0048] 2) The carbon black powder or the mixture of carbon black powder and carbon fiber, deionized water, and dispersant are configured into a uniform slurry, wherein the amount of each component is: carbon black powder or the mixture of carbon black powder and carbon fiber is the slur...

Embodiment 1

[0053] Weigh 60.0080g of 60% PTFE emulsion into a 250mL beaker, add 60-180g of deionized water, and stir with a magnetic stirring bar for about 15min to make it evenly dispersed. Pour 10-30% PTFE solution into a clean petri dish, immerse the cut carbon paper or carbon cloth (cleaning, drying, weighing) into the solution horizontally, then put it into a vacuum oven, and adjust the vacuum to 200Pa, after soaking for 1min, take out the carbon paper, blot the solution on the edge of the carbon paper or carbon cloth with filter paper, and then dry it horizontally (about 6min). Then put the carbon paper or carbon cloth into a high-temperature oven, set the temperature at 70°C, and take it out after drying for about 6 minutes. Then put the carbon or carbon cloth paper in an oven and sinter at 350°C for 30 minutes, so that the loading capacity of PTFE is 1-10mg.cm -2 .

[0054] Weigh 3.0 g of carbon fiber powder with a 50 ml beaker. Add 9ml of deionized water into a 100ml beaker, a...

Embodiment 2

[0057] Weigh 60.0080g of 60% PTFE emulsion into a 250mL beaker, add 60-180g of deionized water, and stir with a magnetic stirring bar for about 15min to make it evenly dispersed. Pour 10-30% PTFE solution into a clean petri dish, immerse the cut carbon paper or carbon cloth (cleaning, drying, weighing) into the solution horizontally, then put it into a vacuum oven, and adjust the vacuum to 200Pa, after soaking for 1min, take out the carbon paper, blot the solution on the edge of the carbon paper or carbon cloth with filter paper, and then dry it horizontally (about 6min). Then put the carbon paper or carbon cloth into a high-temperature oven, set the temperature at 70°C, and take it out after drying for about 6 minutes. Then put the carbon or carbon cloth paper in an oven and sinter at 350°C for 30 minutes, so that the loading capacity of PTFE is 1-10mg.cm -2 .

[0058] Weigh 3-20g of acetylene black powder or other carbon black in a 200ml beaker, add a certain concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com