Anti-cracking railway digital signal cable

A technology for digital signal cables and railways, applied in the direction of communication cables, insulated cables, cables, etc., can solve problems such as cable sheath cracking, potential safety hazards, affecting cable transmission and service life, and achieve the effect of enhancing service life and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The implementation of the railway digital signal cable of the present invention will be described in detail below in conjunction with the accompanying drawings:

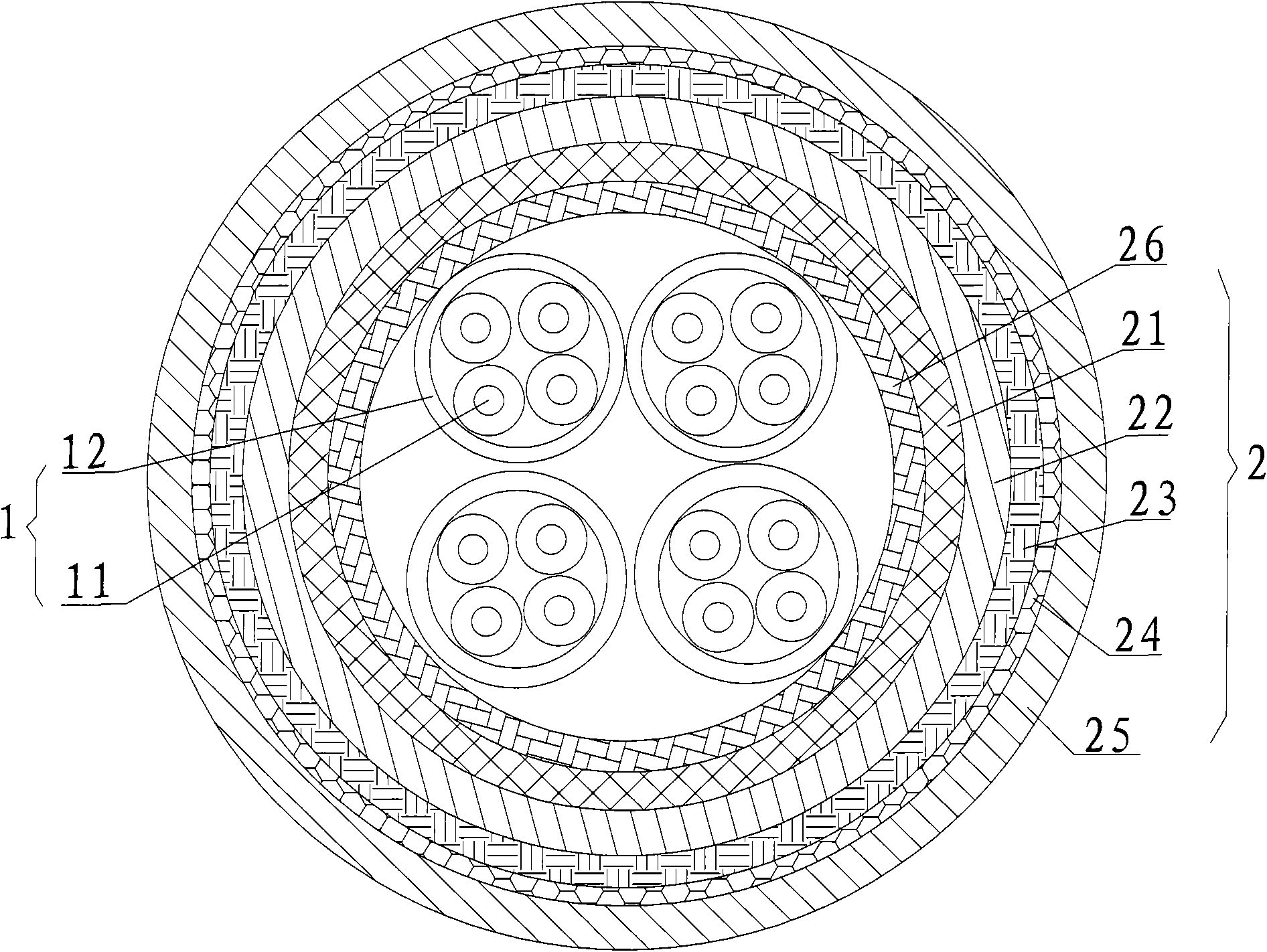

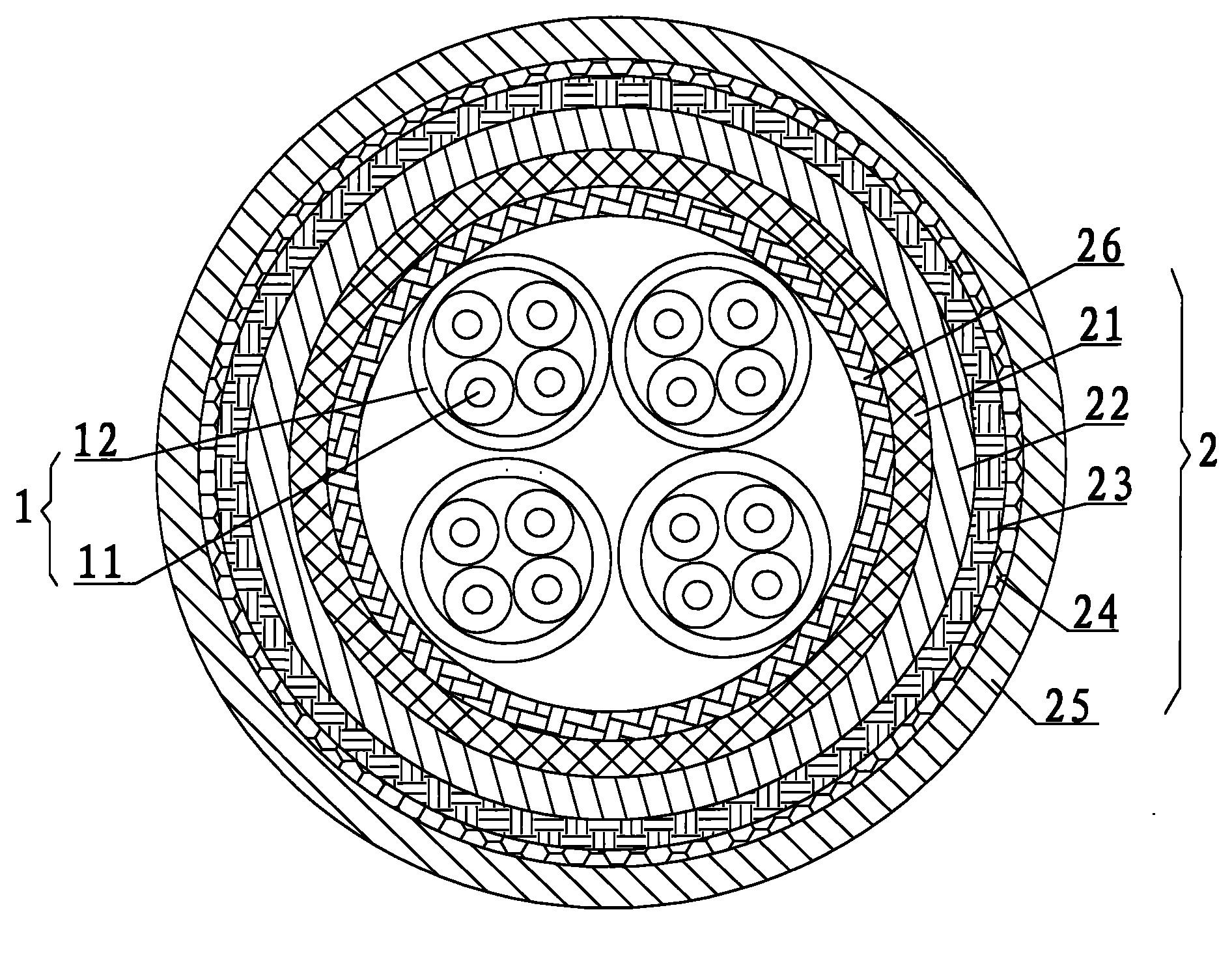

[0011] Such as figure 1 The shown cable, which is mainly used on railway lines, mainly includes a cable core and a sheath 2 covering the outer periphery of the cable core, wherein the cable core includes a plurality of wire group units 1, and each wire group unit 1 is composed of four Single wires 11 are twisted, and polyester yarn 12 is wrapped around them. In this embodiment, there are four wire group units 1 in the cable, and each wire group unit 1 is formed by twisting four single wires 11, and four The four-wire group unit 1 is wrapped by a non-hygroscopic insulating material tape 26, and the sheath 2 is located on the outer periphery of the tape 26. In this embodiment, the sheath 2 includes argon arc welding from the inside to the outside. Alloy aluminum sheath 21, the aluminum sheath 2 is coated with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com