Teaching experimental device for measuring convective heat-transfer coefficient of micro-pipe

A convective heat transfer coefficient and experimental device technology, which is applied in the field of teaching experimental devices for measuring the microtube convective heat transfer coefficient, can solve the problems of large investment, complicated operation, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

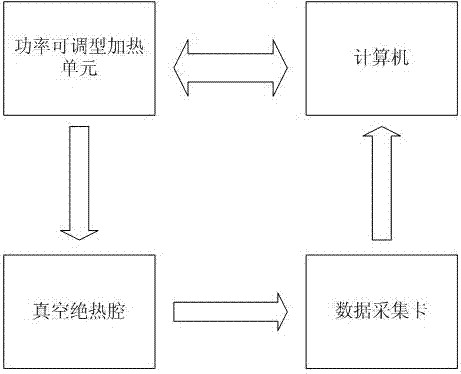

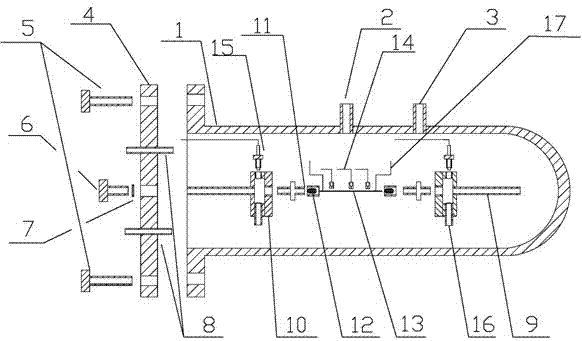

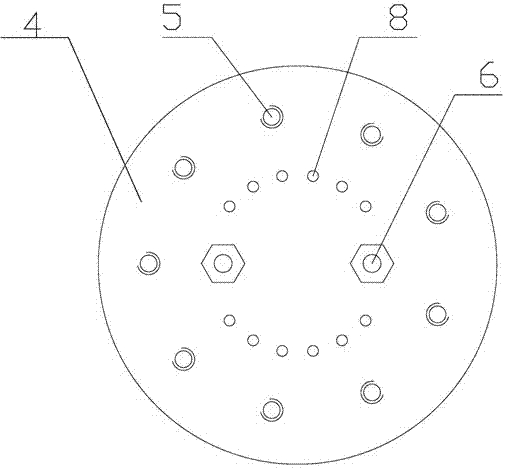

[0012] As shown in the figure, the teaching experimental device for measuring the microtube convective heat transfer coefficient includes a connected vacuum insulation chamber, a power adjustable heating unit, a data acquisition card and a computer, wherein the vacuum insulation chamber includes a stainless steel outer chamber 1, chamber pressure Detection port 2, air exhaust port 3, insulating sealing wiring panel 4, bolt 5, fastener 6, O-ring 7, terminal block 8, inlet and outlet pipe 9, mixing chamber 10, metal two-way joint 11, fluororubber gasket 12 , micron metal tube 13, 50μm thermocouple 14, Pt100 temperature probe 15, pressure sensor 16, heating wire 17; stainless steel outer cavity 1 is provided with cavity pressure detection port 2 and air extraction port 3, and the insulating and sealing wiring panel 4 passes through The bolt 5 is connected with the stainless steel outer cavity 1, the terminal 8 is fixed on the insulating and sealed wiring panel 4, the side of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com