Method for synthesizing mono-dispersed multicomponent compound nanocrystals

A compound and monodisperse technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of high production cost, low production efficiency, and inability to synthesize more than binary compounds, so as to reduce pollution and waste , Reduce production costs, shorten the effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, add 0.25mmol of zinc acetate, 0.25mmol of stannous chloride and 0.5mmol of copper chloride into 30mL of triethylene glycol, and under the protection of argon (or nitrogen, helium, neon), heat the solution to 100- 160°C for 30 minutes to remove water and oxygen therein, and then heated to 220°C to prepare the alcohol phase metal source mixed solution.

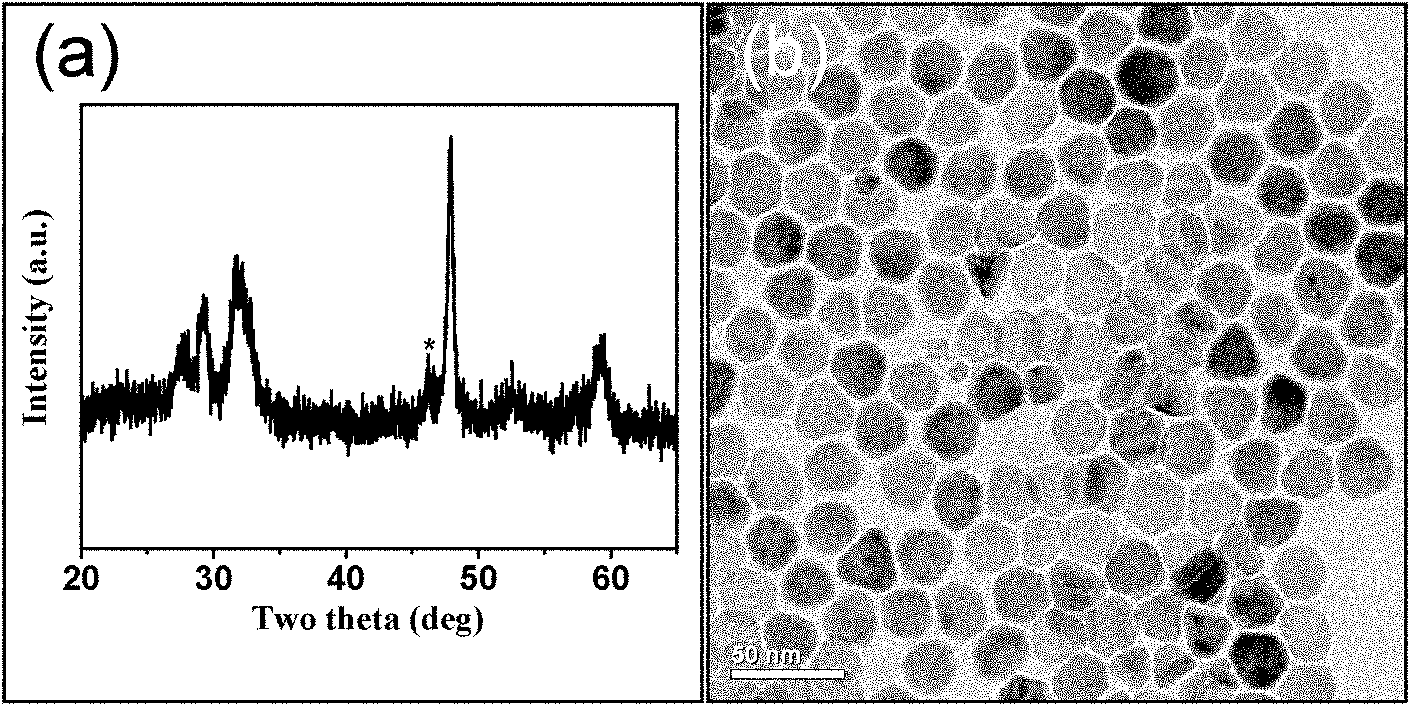

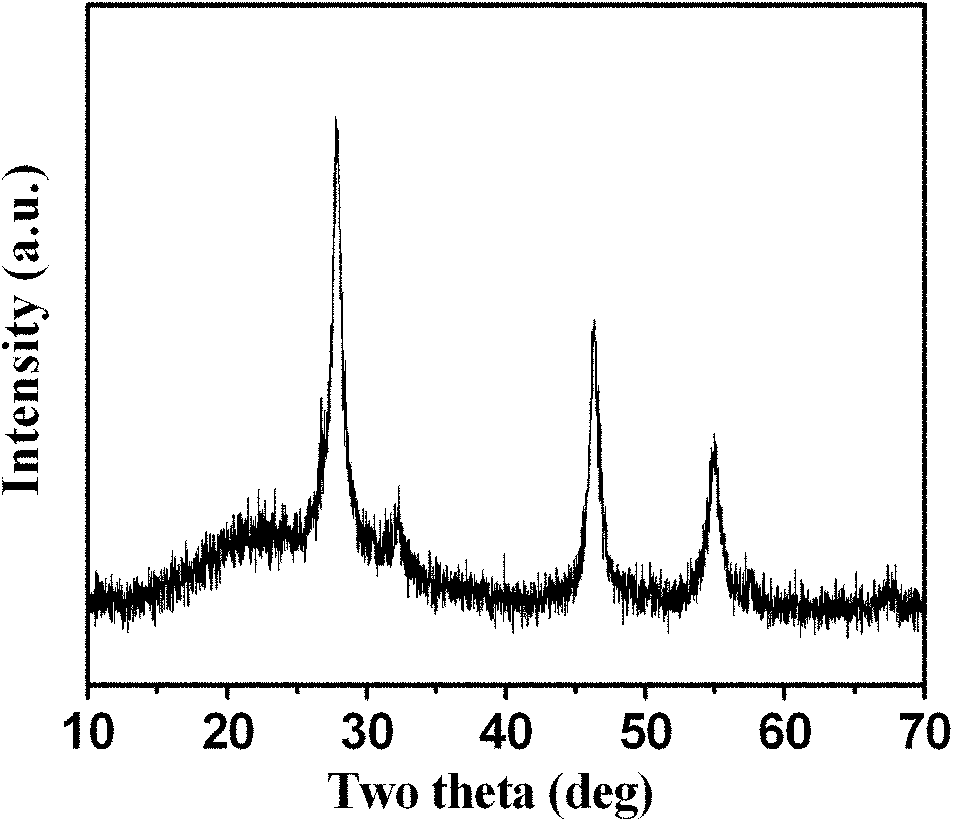

[0030] Dissolve 1mmol of sulfur powder in 2mL of octadecene at 120°C, and then add 0.5g of octadecylamine to this solution to form an oil phase solution; quickly inject this oil phase solution into the above-mentioned alcohol phase metal source mixed solution, The solution turned black immediately, and after keeping the reaction for 1 hour, it was cooled naturally. After the solution is cooled to room temperature, the layers will be separated automatically. The upper layer is drawn out with a needle, and 10 mL of ethanol (ethanol can be replaced by methanol or acetone) is added, and centrifuged to make it precipita...

Embodiment 2

[0032] All the reaction raw materials and operating methods used are the same as in Example 1, except that the sulfur injection temperature is increased to 240°C to obtain monodisperse Cu 2 ZnSnS 4 Nanocrystalline.

Embodiment 3

[0034]All the reaction raw materials and operating methods used are the same as in Example 1, except that the sulfur injection temperature is increased to 280°C to obtain monodisperse Cu 2 ZnSnS 4 Nanocrystalline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com