Microarc oxidation-based surface modifying method for air-conditioner parts of vehicle

A technology of micro-arc oxidation and automobile air conditioning, applied in the direction of anodic oxidation, etc., can solve the problems of large sewage discharge, sewage discharge, water consumption, etc., achieve high production efficiency, expand exports, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

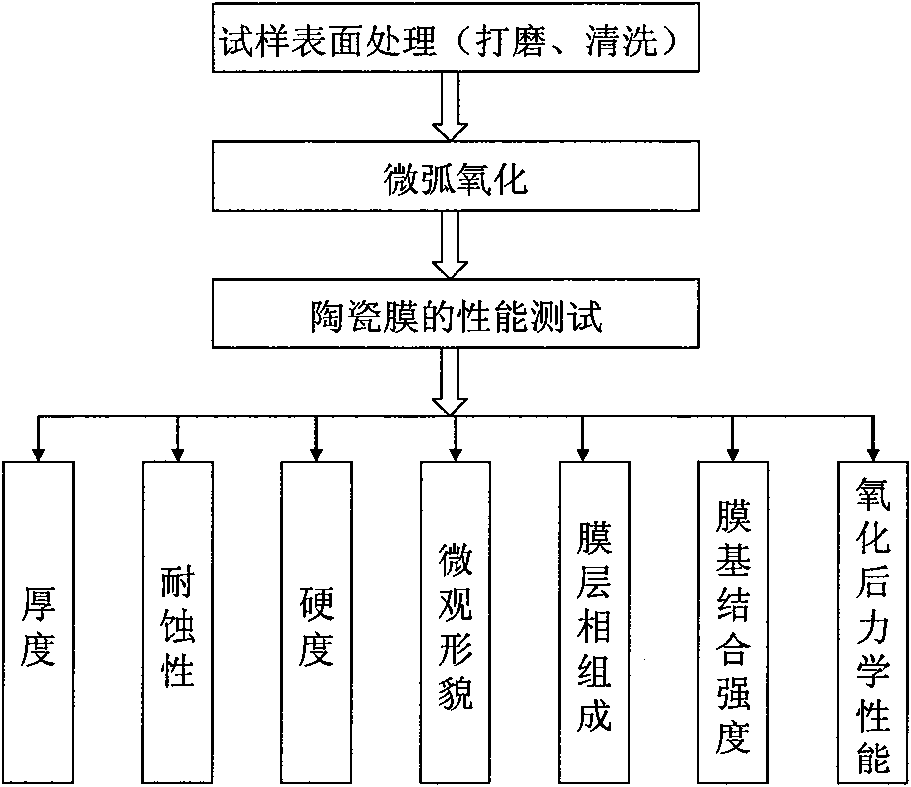

[0020] With reference to accompanying drawing, further illustrate the present invention:

[0021] The surface modification method of the automobile air-conditioning accessories based on micro-arc oxidation, comprises the following steps:

[0022] 1. Remove the surface grease of the parts to be processed, and use a grinder to grind the surface of the parts to remove the burrs on the surface;

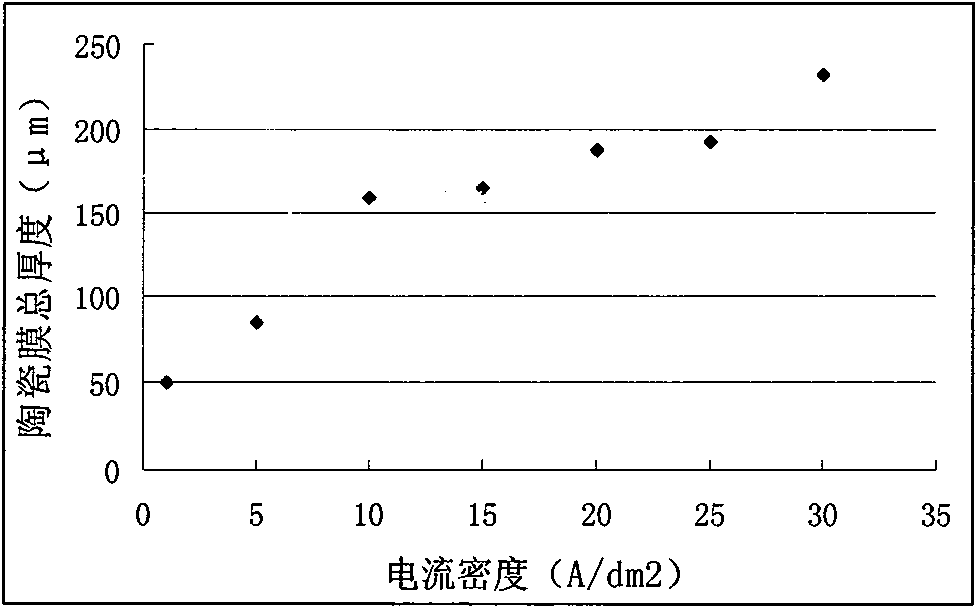

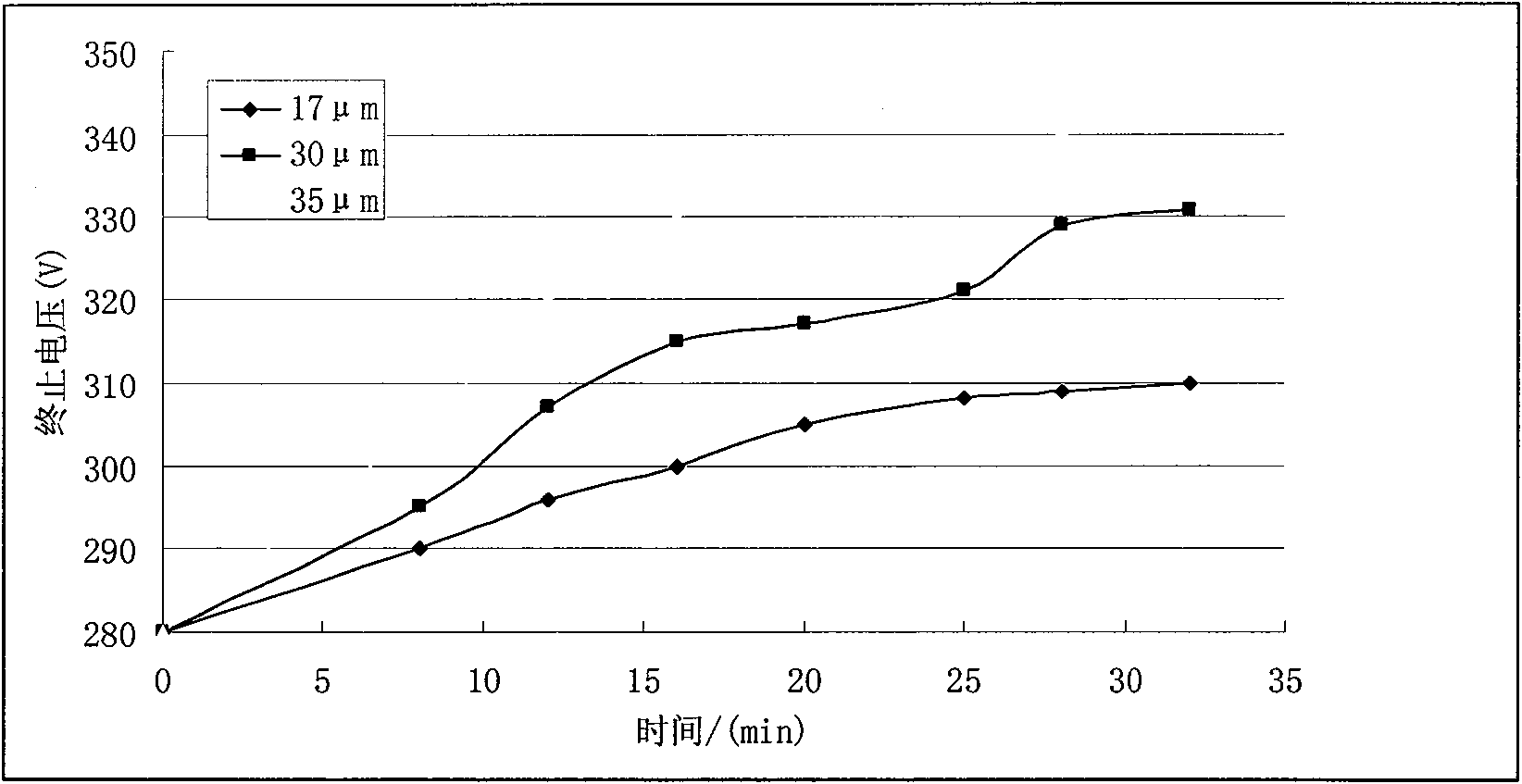

[0023] 2. Put the polished parts into the micro-arc oxidation tank, and form a dense micro-arc oxidation film on the surface of the parts through micro-arc oxidation; during micro-arc oxidation, the pulse frequency of the power supply is 600-800HZ, and the pulse duty The ratio is 20%, the number of positive pulses is 20, the number of negative pulses is 1, and the current density is 5-20dm 2 , the voltage is 0-350V, the electrolyte temperature is 15-45°C, and the micro-arc oxidation time is 5-45min; the electrolyte for micro-arc oxidation includes silicate 7-11g / L, boric acid 1.5-4.5g / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com