Fuel feeding method of direct liquid fuel cell system

A liquid fuel cell and feeding method technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve the problems of increasing system energy consumption, fuel utilization rate and system energy density, less public patents, and reducing system energy Density and system reliability and other issues, to achieve the effect of reducing volatile loss, convenient and flexible manufacturing and use, and improving fuel utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

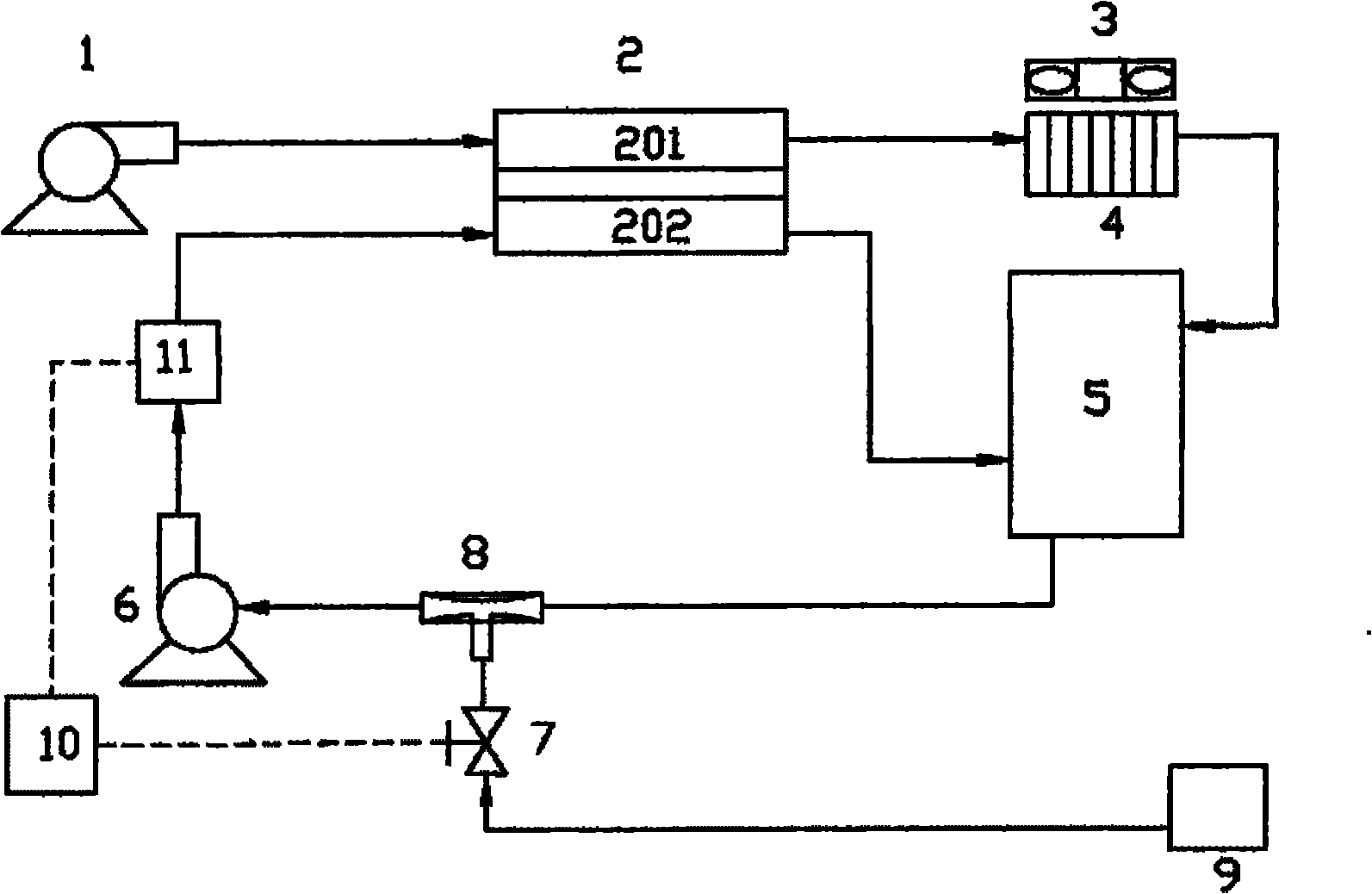

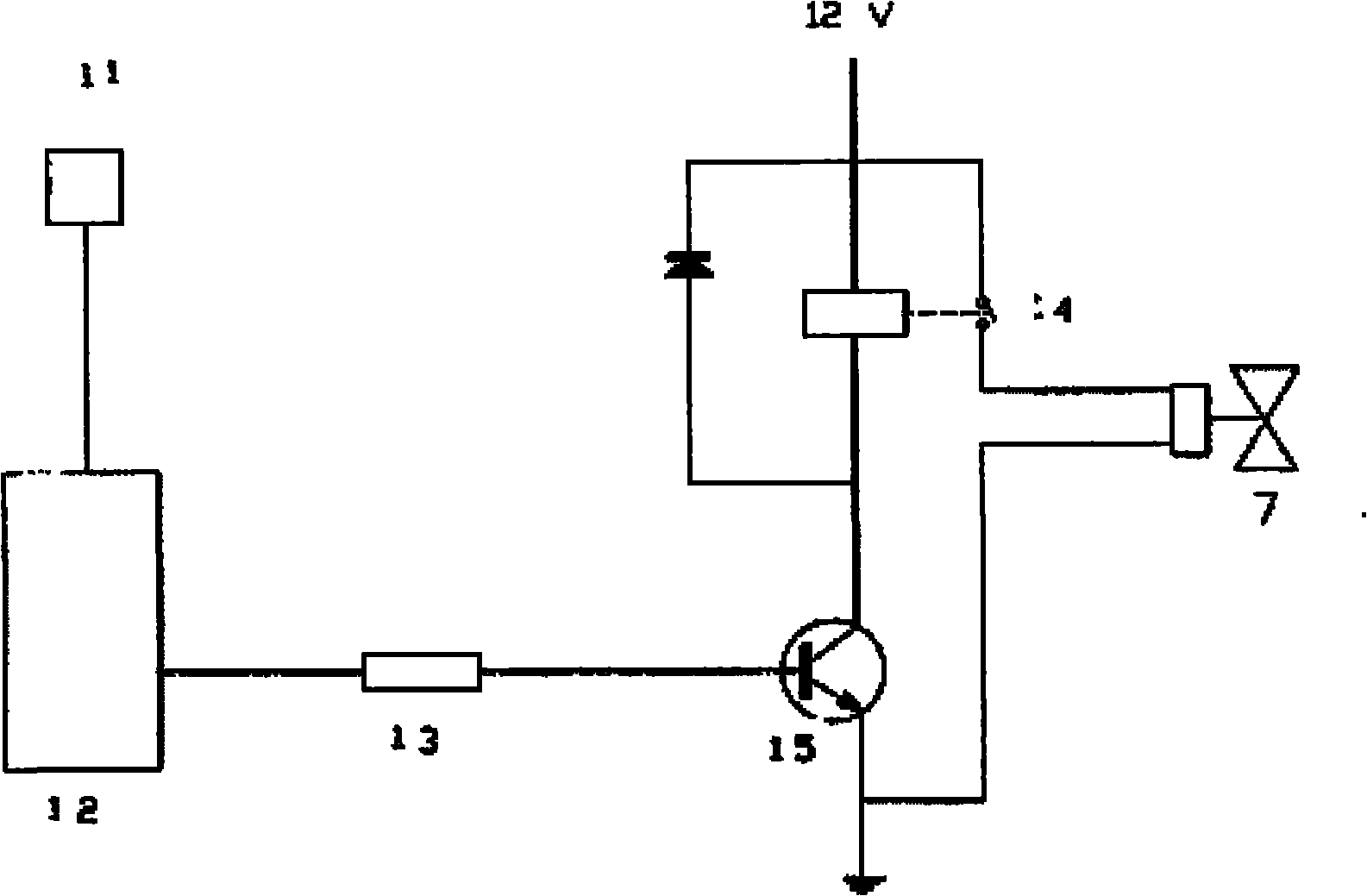

[0023] figure 1 It is a schematic flow chart of the method for feeding pure methanol to the DMFC system of the present invention. The DMFC system shown includes direct methanol fuel cell stack 2, air pump 1, fan 3, heat exchanger 4, gas-liquid separator 5, liquid pump 6, pure methanol tank 9, throttle valve 8, solenoid valve 7, control Device 10 and methanol concentration sensor 11.

[0024] During the working process of the above-mentioned DMFC system, its ambient temperature is room temperature (25°C), and its external output power is constant at 50W. During operation, the air pump 1 transports the outside air to the cathode 201 of the direct methanol fuel cell stack 2, and the outlet of the cathode 201 The gas-liquid mixture enters the gas-liquid separator 5 after being condensed by the heat exchanger 4. In order to improve the heat exchange efficiency of the system, a fan 3 is arranged above the heat exchanger 4; the gas-liquid mixture at the outlet of the anode 202 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com