Liquid damping time delayer

A technology of liquid damping and delay device, applied in the direction of liquid shock absorber, shock absorber, shock absorber, etc., can solve the problems of large delay time change, easy blockage of tiny holes, large compressed gas, etc. Reliability and safety, reducing its own volume, reducing the effect of delay effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

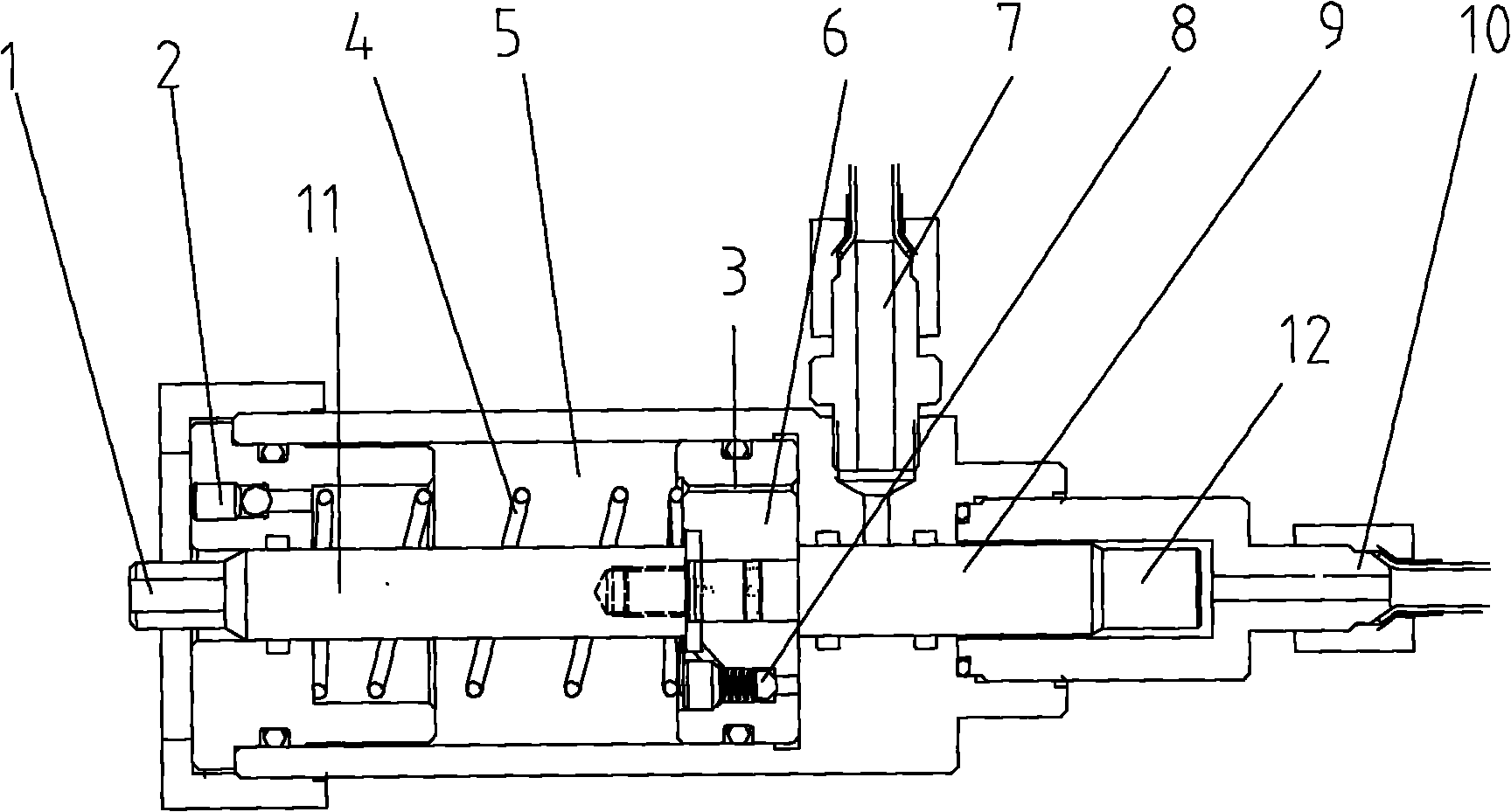

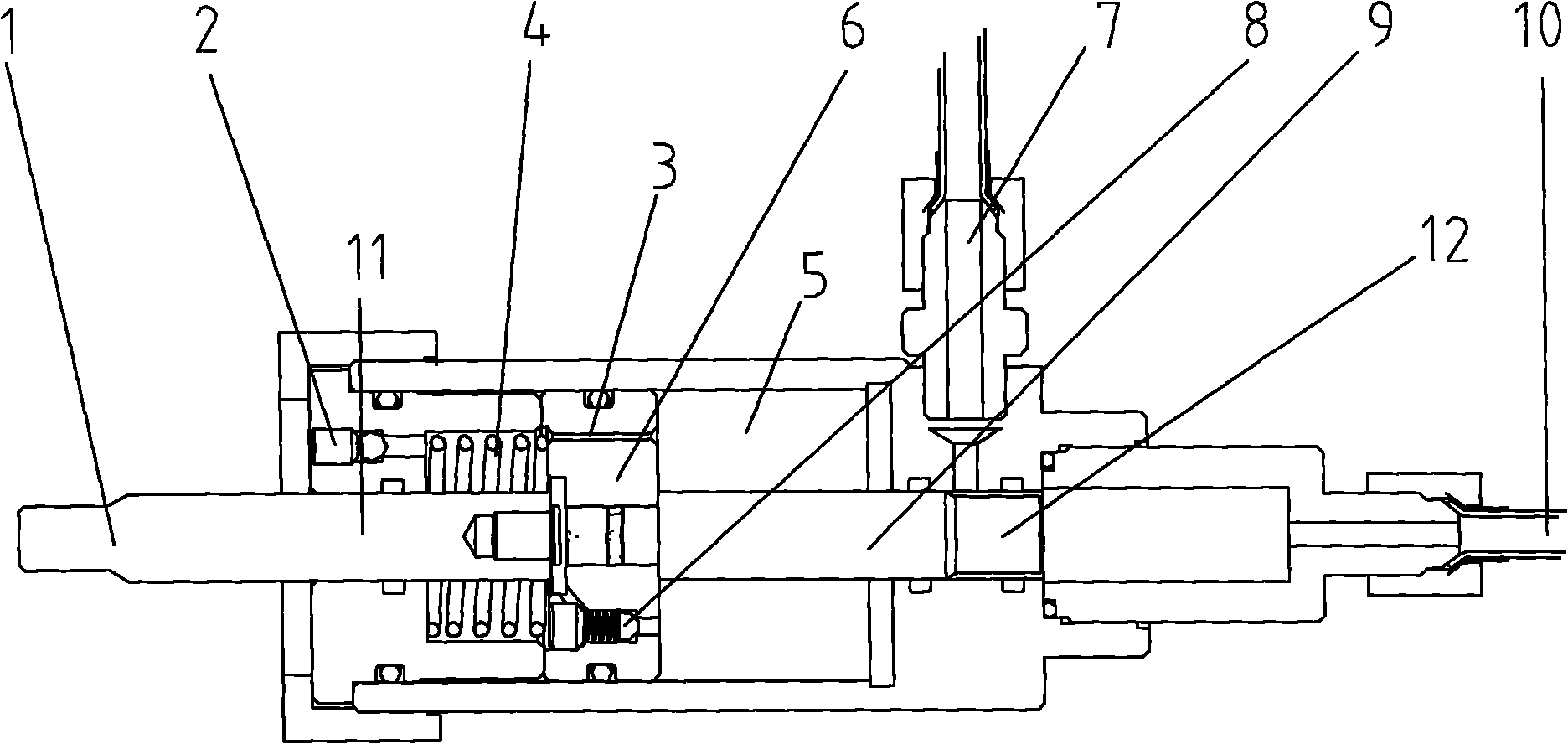

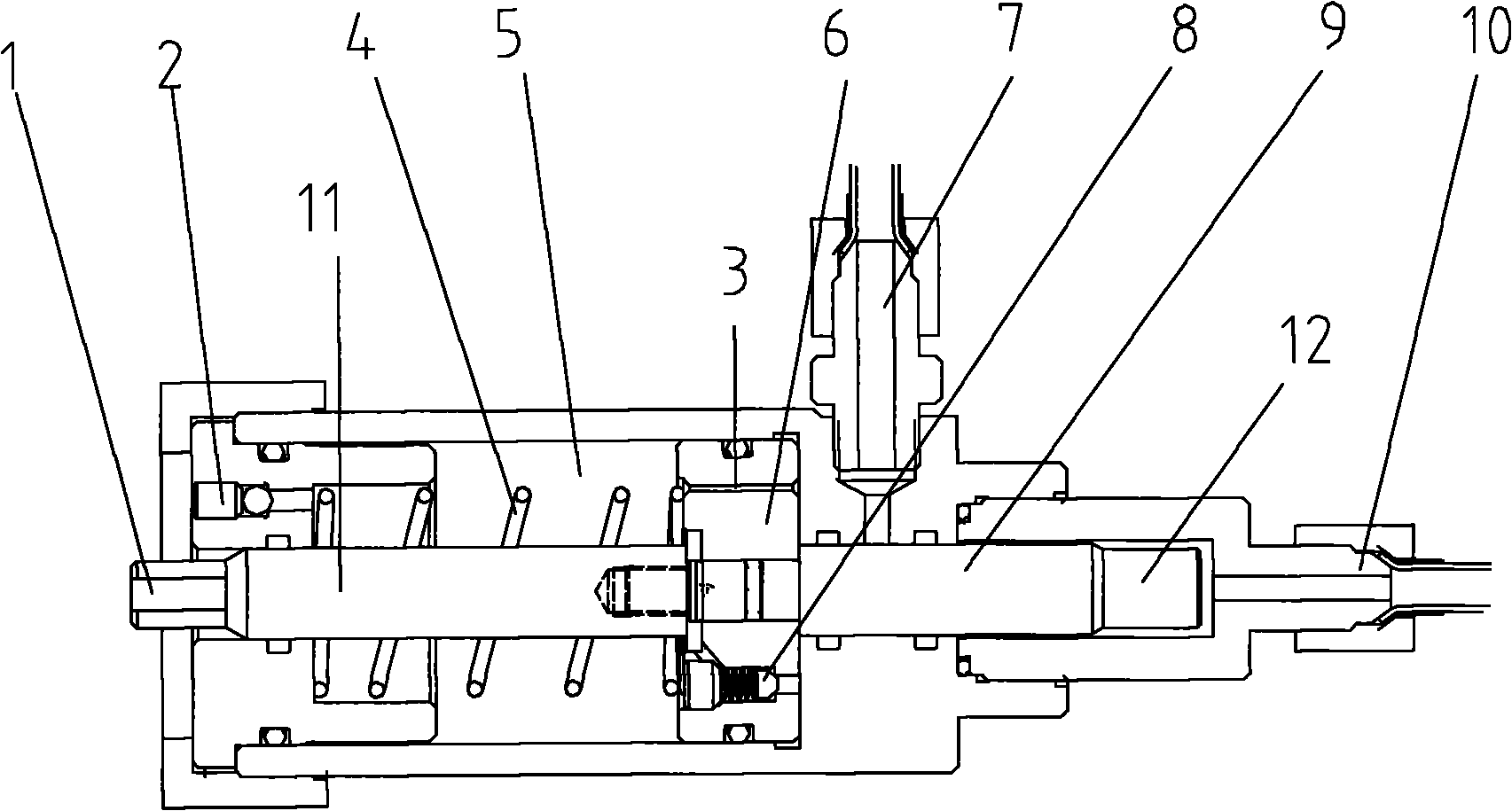

[0023] The present invention will be further described below in combination with preferred implementation methods with reference to the accompanying drawings.

[0024] The invention relates to a liquid damping delayer. including such as figure 1 and figure 2 The gas exchange device and damping device shown. The gas exchange means and the damping means are interconnected.

[0025] The gas exchange device includes an air inlet port 10 , a small piston 9 , a piston reducing end 12 and an air outlet port 7 . The small piston 9 and the piston variable diameter end 12 are located inside the gas exchange device, and the small piston 9 and the piston variable diameter end 12 are connected to each other; the small piston 9 is connected to the inner wall of the gas exchange device Complete fit; the diameter of the reduced diameter end 12 of the piston is smaller than the diameter of the small piston 9; the air inlet port 10 and the air outlet port 7 are orthogonally distributed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com