Method for producing flame-retardant polyester staple fibers by utilizing recovered polyester bottle chips

A technology of flame retardant polyester and polyester bottle flakes, applied in fiber processing, fire-retardant flame retardant filament manufacturing, single-component polyester rayon, etc. It can solve the problem that the recycled polyester bottle flakes have many impurities and cannot produce high-end chemical fibers. products and other issues, to achieve the effect of being conducive to environmental protection, improving cost performance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

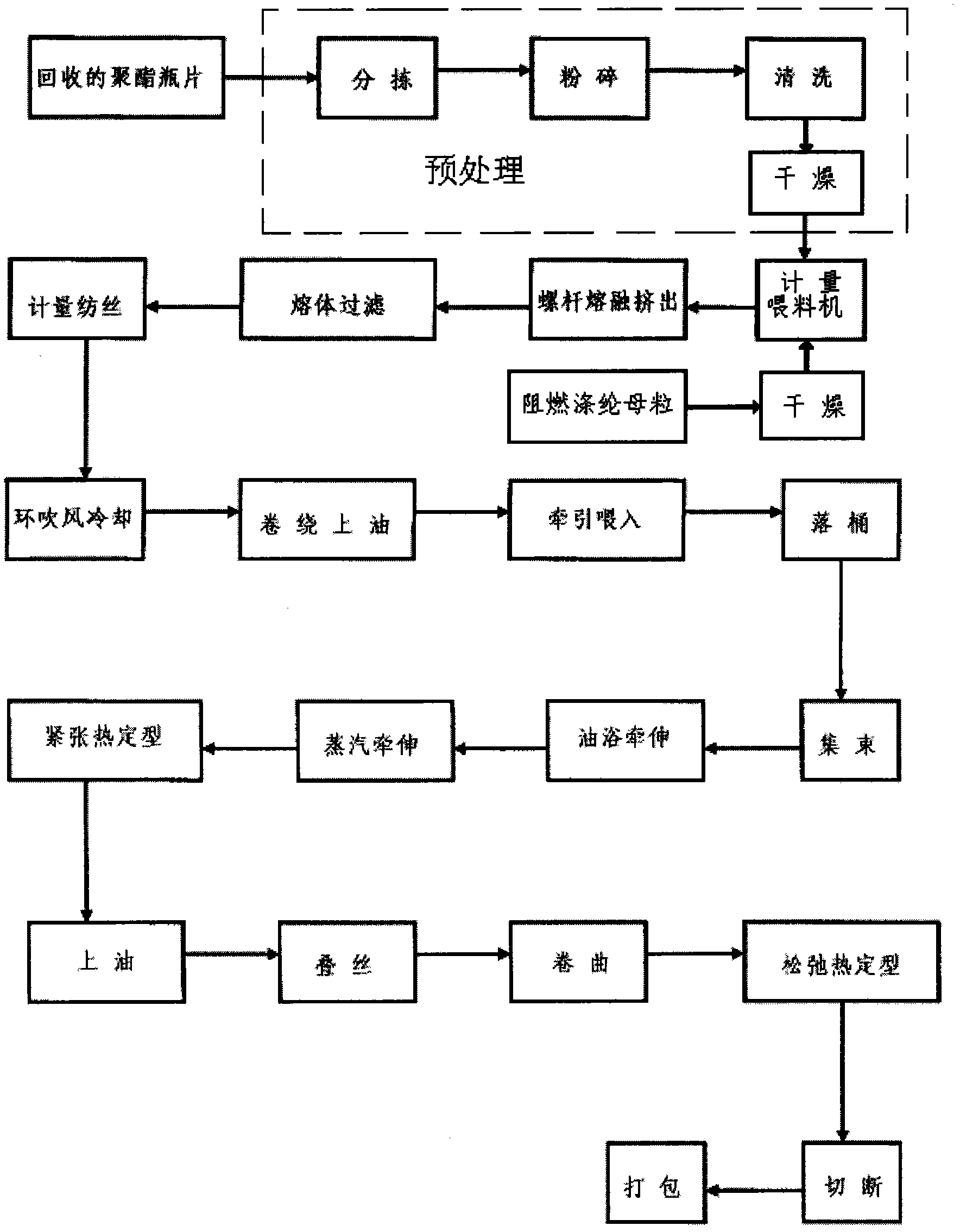

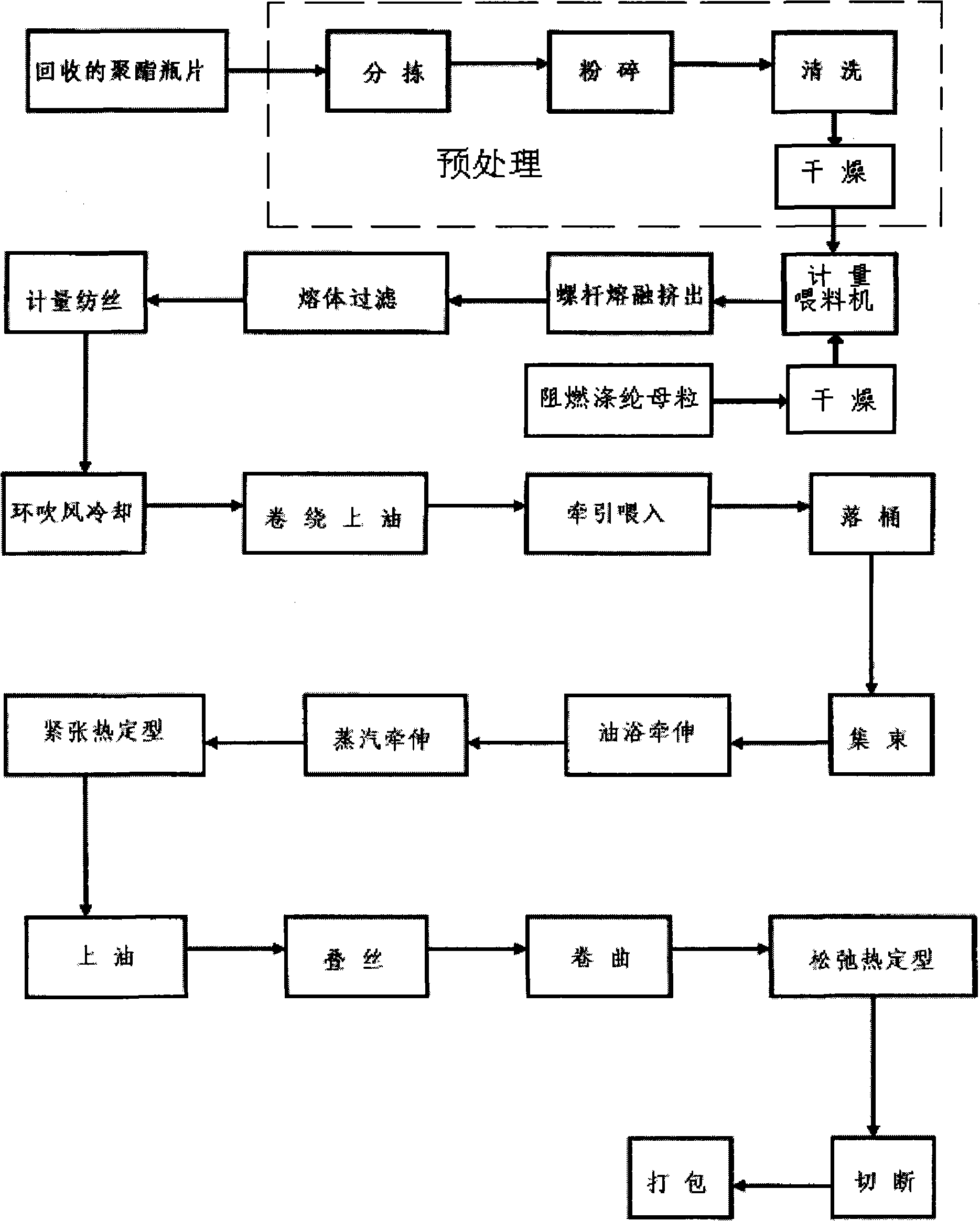

[0016] A method for producing flame-retardant polyester staple fibers using recycled polyester bottle flakes according to the present invention, see figure 1 , first pretreatment and drying of recycled waste PET bottle flakes. Pretreatment includes a series of raw material preparations such as sorting, crushing, and cleaning the recovered polyester bottle flakes, and then undergoes high-temperature vacuum drying. The drying temperature is 130-160°C, the vacuum degree is 0.06-0.10Mpa, and the drying time is After 8 to 12 hours, the moisture content of the dried bottle flakes is ≤100PPm.

[0017] At the same time, the flame-retardant polyester masterbatch is dried. The flame-retardant polyester masterbatch is put into a large sealed silo, and the dry hot air is introduced into the bottom of the silo. The temperature is kept at 120-140°C, and the drying time is 10-12 hours. , the moisture content of the flame-retardant polyester masterbatch after drying is controlled below 60PPm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com