Heavy oil catalytic cracking method and device by double-area coupling and catalyst tandem

A heavy oil catalysis and catalyst technology, applied in the field of petroleum processing, can solve the problems such as the deterioration of catalytic cracking raw materials, and achieve the effects of solving the increasingly deteriorated quality, improving the yield and liquid yield, and improving the average activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

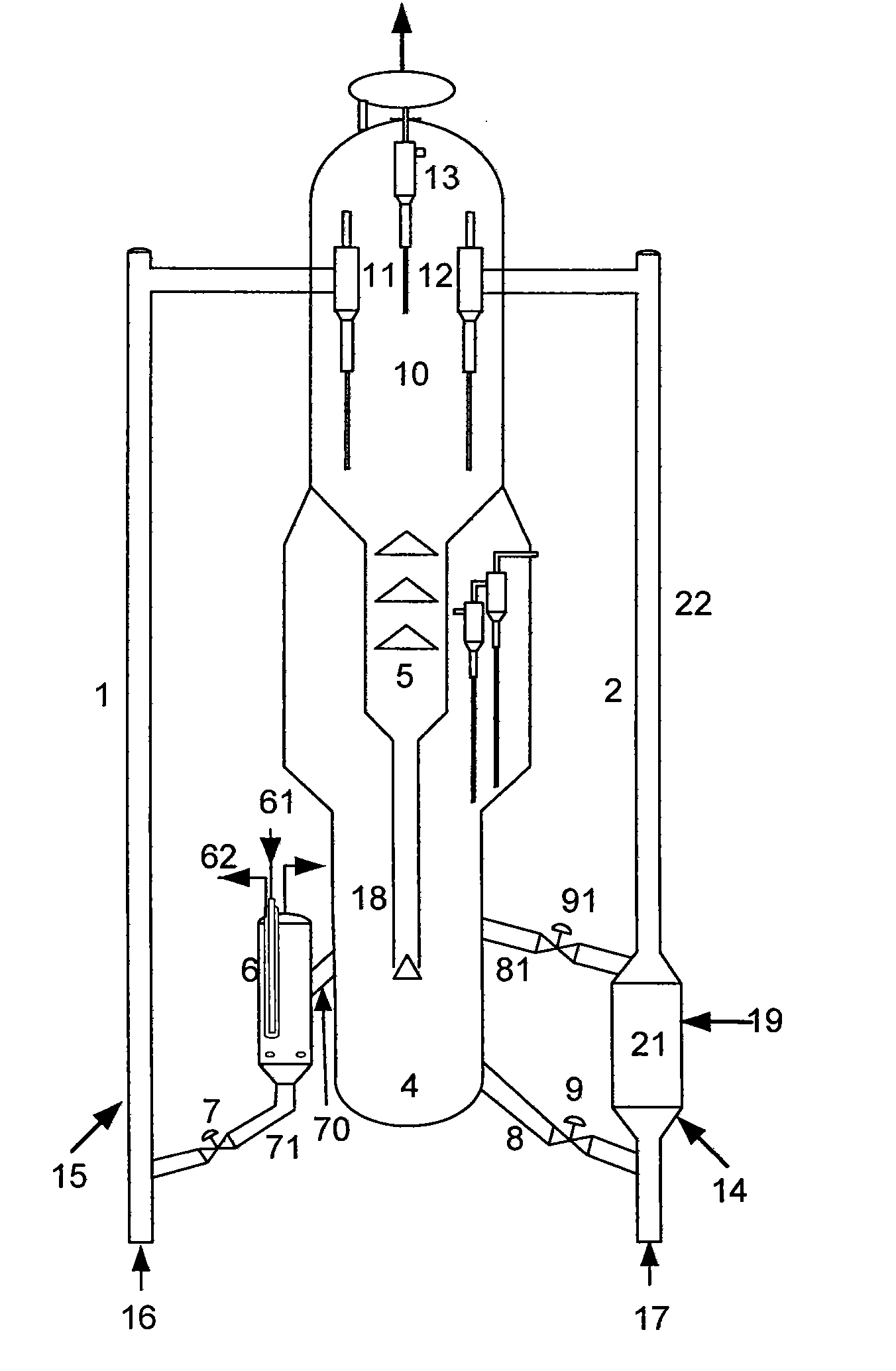

[0043] see figure 1 The flow process, in the catalyst regenerator 4 of the heavy oil catalytic cracking reaction unit (the present invention is the coaxial catalytic cracking unit that the settler and the regenerator are coaxially arranged as an example, and the settler can also be used in the production on the upper part of the riser reactor However, a conventional riser reactor 1 is arranged next to the high and low side-by-side catalytic cracking units arranged in parallel with the regenerator, and a part of the high-temperature regenerated catalyst in the catalyst regenerator 4 passes through the catalyst delivery pipe 6 and its The regenerated catalyst slide valve 7 on the top enters the riser reactor 1 and flows upward under the lifting action of the lifting gas 16 and high-quality catalytic feedstock oil 15 (the feedstock oil is distilled and cut in advance, and the residual carbon value is less than 2wt%. Embodiment same) contact reaction, be 100~300 ℃ and opening degr...

Embodiment 2

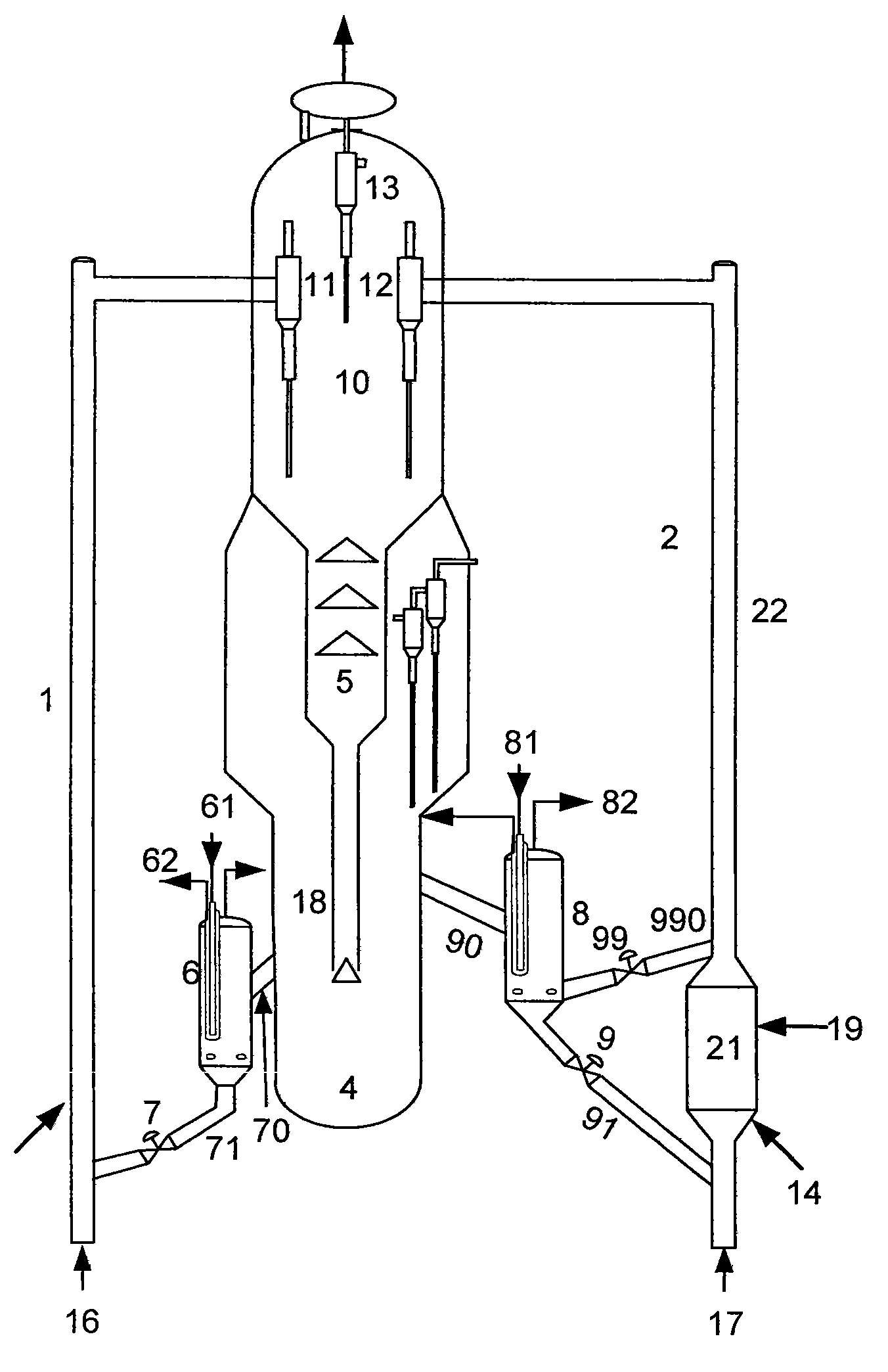

[0046] see figure 2 In the flow chart shown, a conventional riser reactor 1 and a regenerated catalyst cooler 6 are arranged next to the catalyst regenerator 4 of the heavy oil catalytic cracking reaction unit, and a part of the high-temperature regenerated catalyst in the catalyst regenerator 4 enters the regenerated agent for cooling through the catalyst delivery pipe 70 6, the cooling medium enters through the inlet 61 and flows out through the outlet 62, and the temperature of the regenerated catalyst entering the cooler 6 is cooled from 680 to 710°C to 580 to 670°C, and the cooled catalyst passes through the regenerated inclined pipe 71 and The regenerated catalyst slide valve 7 enters the riser reactor 1, and flows upward under the lifting action of the lifting gas 16 to contact and react with the high-quality catalytic raw material oil 15. The reaction conditions of the riser reactor 1 are: the preheating temperature of the raw material is 100-300°C, The temperature of...

Embodiment 3

[0050] see image 3 As shown in the flow process, a conventional riser reactor 1 and a regenerated catalyst cooler 6 are arranged next to the catalyst regenerator 4 of the heavy oil catalytic cracking reaction unit, and a part of the high-temperature catalyst in the catalyst regenerator 4 enters the regenerated agent cooler 6 through the catalyst delivery pipe 70 , the cooling medium enters through the inlet 61 and flows out through the outlet 62, and the temperature of the regenerated catalyst entering the cooler 6 is cooled from 680 to 710°C to 580 to 670°C, and the cooled catalyst passes through the regenerated inclined pipe 71 and the regenerated catalyst The sliding valve 7 enters the riser reactor 1, and flows upward under the lifting action of the lifting gas 16 to contact and react with the high-quality catalytic raw material oil 15. The temperature of the regenerated catalyst before the tube reactor 1 is 580-670°C, the reaction temperature is 460-520°C, the catalyst-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com