Light emitting diode with oxide nano array structure and preparation method thereof

A technology of light-emitting diodes and nano-arrays, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as difficulty in repairing, and achieve the effects of reducing the current concentration effect, improving the light output rate, and reducing the effect of total reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

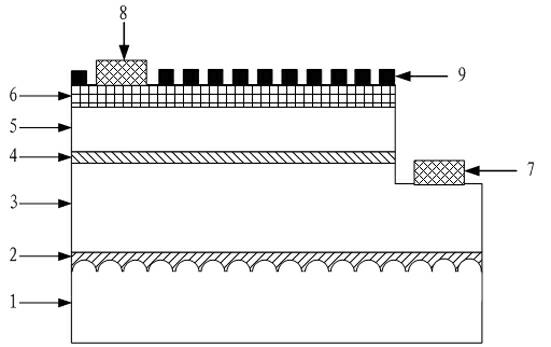

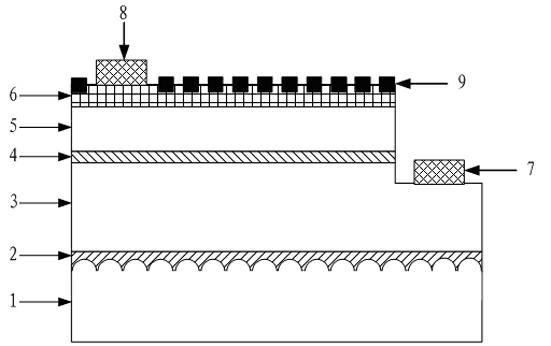

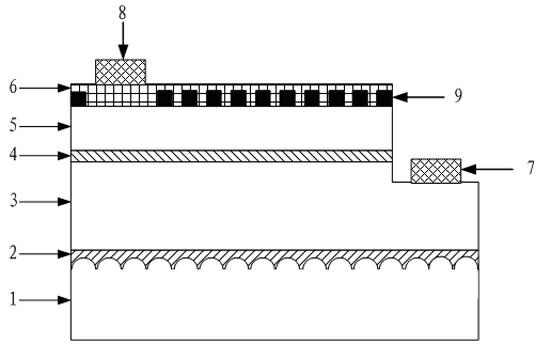

[0062] Such as figure 1 As shown, in the first implementation of the light-emitting diode of the present invention, the light-emitting diode includes a substrate 1, a buffer layer 2, an N-type layer 3, an active layer 4, a P-type layer 5, and a layer disposed on the P-type layer in sequence. Transparent conductive layer 6 on 5, N-type layer 3 is provided with N-electrode 7, P-type layer 5 is provided with P-electrode 8, N-type layer 3 is an N-type GaN layer, and P-type layer 5 is a P-type GaN layer. The surface of the transparent conductive layer 6 is covered with oxide particles 9 distributed in an array. Wherein, the material of the oxide particles 9 is Al 2 o 3 、 Ta 2 o 5 、TiO 2 , ZnO, ZrO 2 One or a combi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com