Back surface field aluminium paste for solar cells

A solar cell and back field aluminum paste technology, applied in the field of metal pigments, can solve the problems of poor conductivity and low photoelectric conversion efficiency of aluminum paste, and achieve the effect of low warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

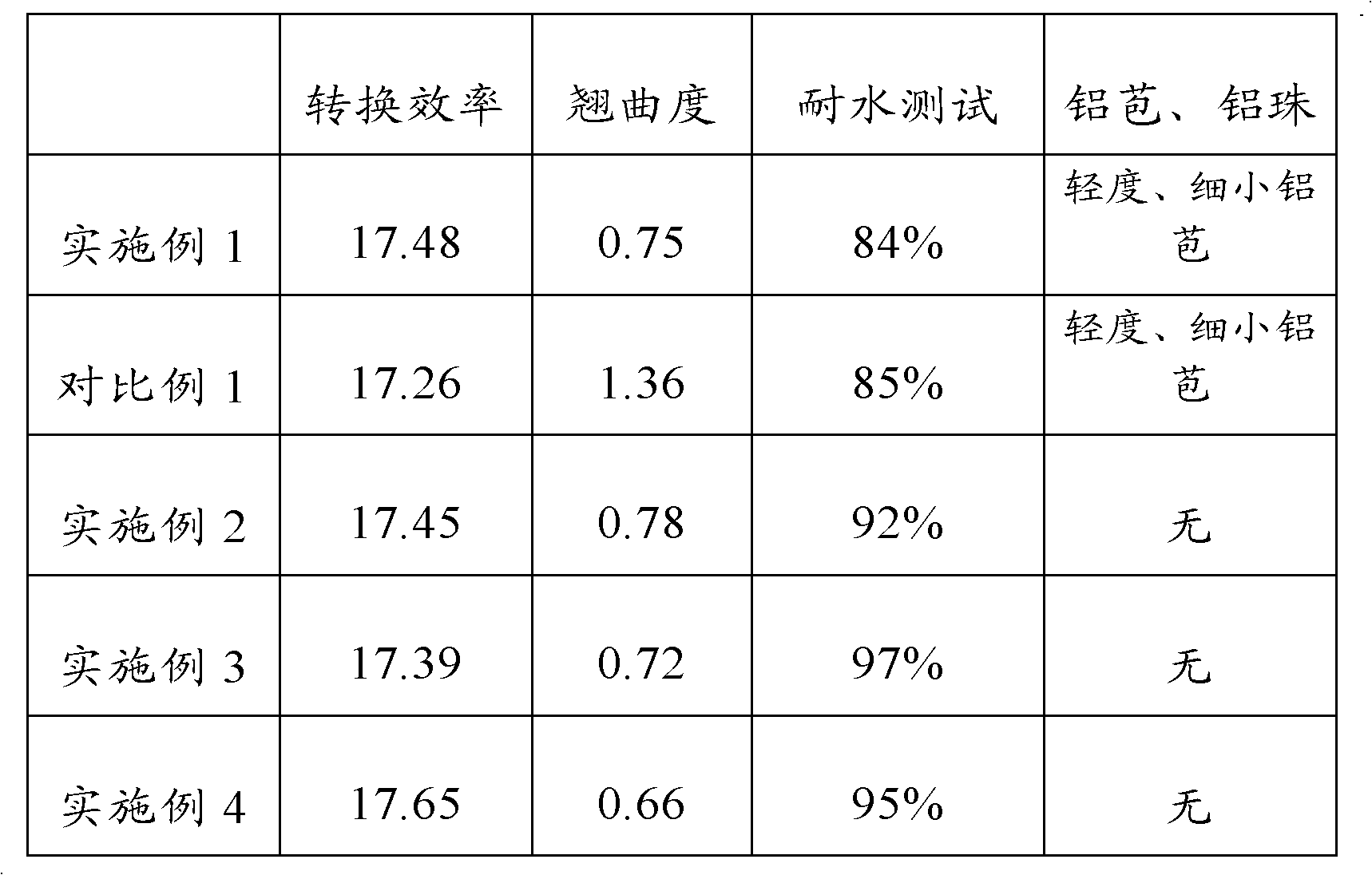

Examples

preparation example Construction

[0105] 2) Preparation of inorganic adhesive

[0106]Weigh the components of the inorganic adhesive according to the formula requirements, mix them in a high-speed mixer, then melt at 1150°C-1250°C, water quench, and ball mill. In the case of using binders with different particle sizes, glass frits with different particle sizes can be obtained by different grinding times. In a specific embodiment of the present invention, the rotating speed of the ball mill is set to 30-50rpm, the inorganic binder B with a D50 value of 2-4 microns is obtained after ball milling for 48 hours, and the D50 value of 1-2 microns is obtained after ball milling for 72 hours. Inorganic adhesive A between microns.

[0107] 3) Preparation of organic vehicle

[0108] Weigh the solvent and resin according to the formula requirements, stir and mix in the reaction kettle, usually at an elevated temperature, for example, at a temperature of 50-80°C, slowly add the required resin into the hot solvent, After...

Embodiment 1

[0111] Aluminum powder treatment: add 50kg of aluminum powder (KY523, KY445, KY456, and KY467 account for 25% each) purchased from Luxi County Jinyuan Powder Material Co., Ltd. into the high-speed mixer, and add it by atomization according to the required amount 3kg combined treatment solution. The joint treatment solution contains 0.3kg titanate (KR-201, ethyl diisostearyl titanate), 0.2kg borate (LD-100P, produced by Yangzhou Lida Resin Co., Ltd.) and 2.5kg ethanol, titanium The ratio of ester to borate is 3 to 2, and the dosage is 1% of the aluminum powder. After adding the liquid, continue mixing for 3 minutes, take out the aluminum powder, place it at 50-70° C., and dry it under vacuum conditions for 6-8 hours to obtain the aluminum powder required for preparing the slurry.

[0112] Preparation of inorganic binder: according to 20 parts of SiO 2 , 18 copies of B 2 o 3 , 13 Al 2 o 3 , 15 Bi 2 o 3 , 16 parts of ZrO 2 Prepare the adhesive with the ratio of 10 parts ...

Embodiment 2

[0119] Treatment of aluminum powder: Add 50kg of aluminum powder (KY523, KY445, KY456, and KY467 each account for 25%) purchased from Luxi Jinyuan Powder Material Co., Ltd. into the high-speed mixer, and atomize according to the required amount Add 5kg of combined treatment solution. The joint treatment liquid contains 0.2kg titanate KR-201, 0.3kg borate (LD-100P, produced by Yangzhou Lida Resin Co., Ltd.) and 4.5kg ethanol, the ratio of titanate and borate is 2 to 3 , the dosage is 1% of the aluminum powder. After adding the liquid, continue mixing for 3 minutes, take out the aluminum powder, place it at 50-70° C., and dry it under vacuum conditions for 6-8 hours to obtain the aluminum powder required for preparing the slurry.

[0120] Preparation of inorganic adhesive: prepare adhesive according to the following ratio:

[0121] Bi 2 o 3 55 copies

[0122] SiO 2 15 copies

[0123] h 3 BO 3 20 copies

[0124] ZnO 5 parts

[0125] al 2 o 3 2 copies...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com