LED (light emitting diode) headlamp of electric automobile

A technology of electric vehicles and LED modules, applied in the direction of headlights, electric light sources, vehicle components, etc., can solve the problems of low electro-optic conversion rate, short service life, high energy consumption, etc., achieve high electro-optic conversion rate, safe and convenient use , Solve the effect of light decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

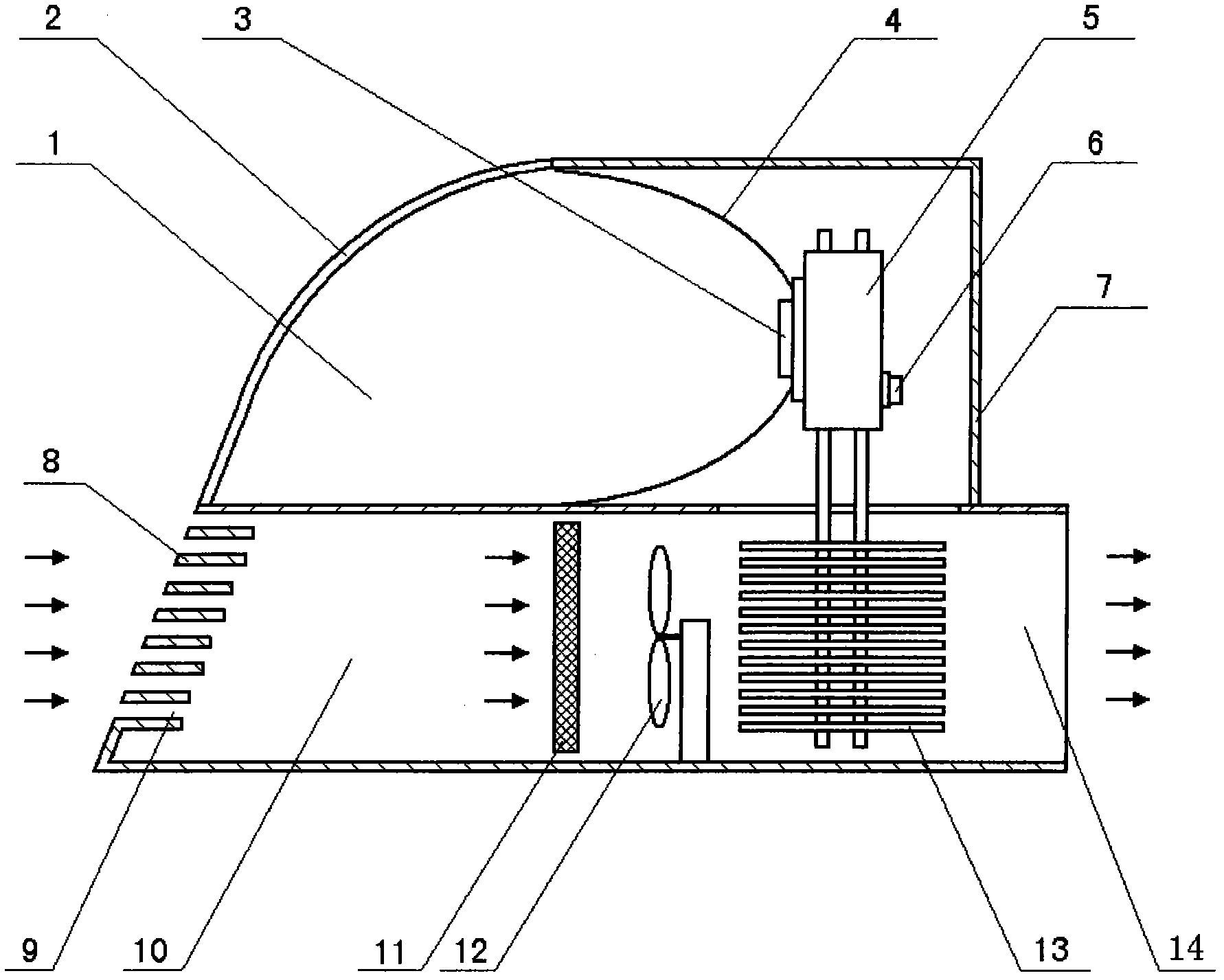

[0008] As shown in the accompanying drawings: the electric vehicle LED headlight includes a housing 7, the housing 7 is provided with a light source cavity 1 and a heat dissipation air duct 10, the front of the light source cavity 1 is provided with a sealed glass cover 2, and a reflector 4 is installed inside the light source cavity 1 And the high-power LED module 3, the back of the high-power LED module 3 is fixed on the heat-absorbing end 5 of the heat pipe radiator, the temperature control switch 6 is installed behind the heat-absorbing end 5 of the heat pipe radiator, and the radiating end 13 of the heat pipe radiator is set There are dense heat dissipation fins, and the heat dissipation end 13 of the heat pipe radiator is placed in the heat dissipation air duct 10 . The heat dissipation air duct 10 is provided with an air inlet 9 and an air outlet 14, the air inlet 9 is provided with a grille 8 to prevent foreign matter from entering, the back of the grille 8 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com