Ultrahigh molecular weight polyethylene abrasion and temperature resistant composite braided rope

A technology of ultra-high molecular weight and polyethylene, applied in the field of textile ropes, can solve the problems of lack of wear resistance and high temperature resistance, heat transfer to the inner rope, etc., and achieve good high temperature resistance, good softness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

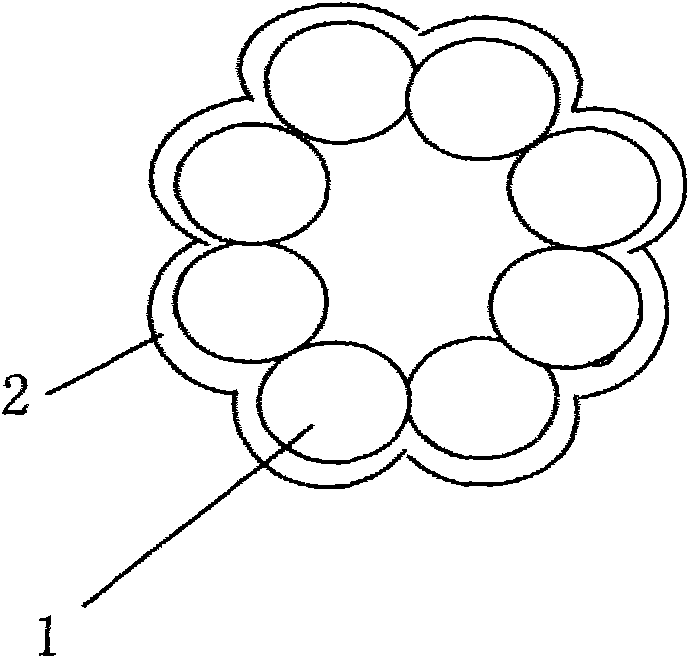

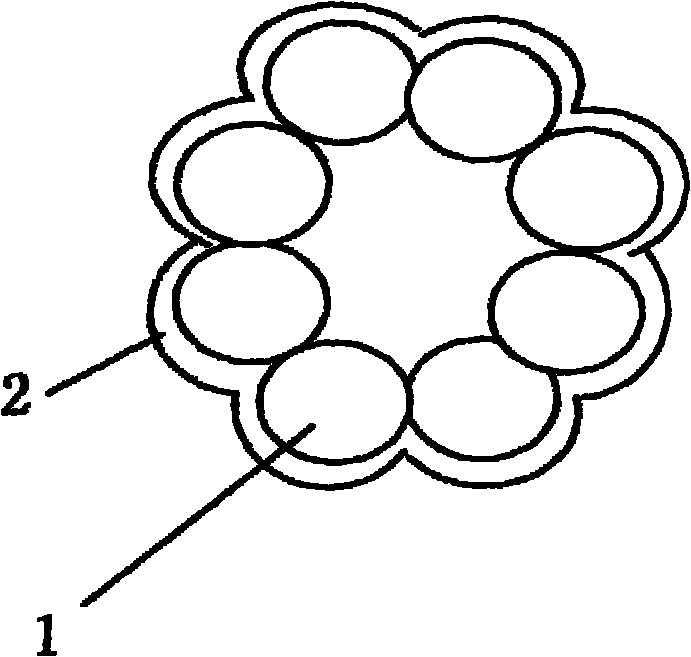

[0007] The present invention (see accompanying drawing) adopts polytetrafluoroethylene and single linear density 1dtex-10dtex fiber, multifilament linear density 200dtex-6000dtex ultra-high molecular weight polyethylene fiber; Merge or twist on the machine to form a rope yarn with a linear density of 200dtex-50000dtex; then use a rope yarn with a linear density of 200dtex-50000dtex to merge or twist into a rope strand 1 on the rope stranding machine (see attached picture); use the rope strands to weave in eight or twelve strands Twisted or braided rope machine, braided into a diameter of 1mm-102mm, linear density (meter weight) 0.5Ktex-7500Ktex (g / m) eight or twelve strands braided twisted or braided rope; twist coefficient (lay length) is the diameter of the rope 3.5-10 times; and then use a plastic extruder to coat the rope surface with a thickness of 1mm-2mm and low melting point (below 100°C) polyethylene, and then coat it with PTFE 2 with a thickness of 1mm-5mm (see attach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com