Amorphous Sb-doped zinc tartrate micro-nano spheres and preparation method thereof

A technology of zinc tartrate and micro-nanospheres, which is applied in the direction of carboxylate preparation, nanostructure manufacturing, nanotechnology for materials and surface science, etc., to achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1) Dissolve zinc nitrate and hexamethylenetetramine in water at a molar ratio of 1:1, prepare an aqueous solution of zinc nitrate and hexamethylenetetramine with a concentration of 0.05M, and add antimony potassium tartrate to the prepared solution , so that the concentration of antimony potassium tartrate is 0.005M, stir evenly to obtain the growth mother liquor;

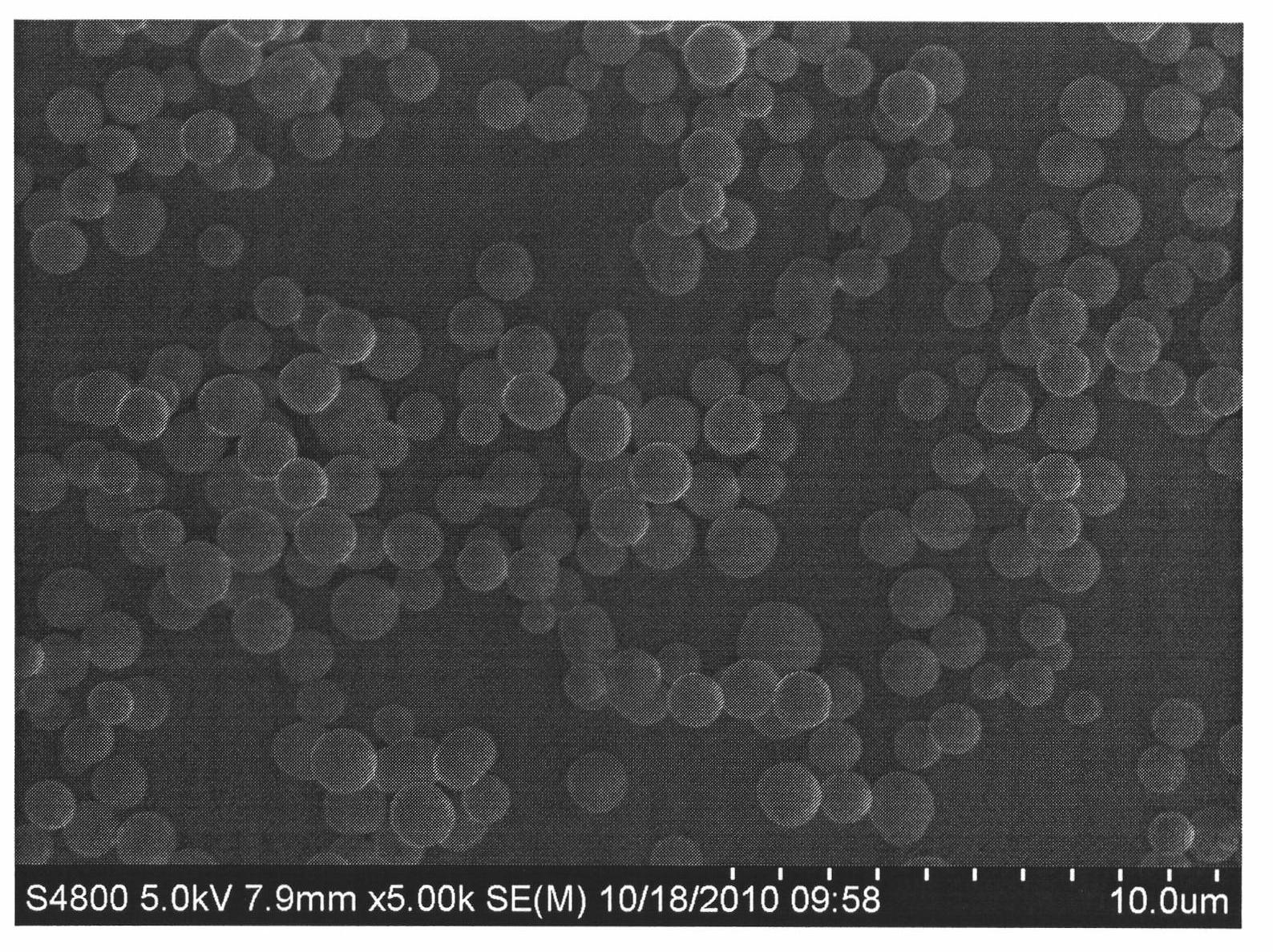

[0015] 2) Put the growth mother solution in step 1) into the reaction kettle, keep the temperature at 90°C for 3 hours, let the solution stand, take the precipitate, wash it repeatedly, centrifuge, and dry to obtain amorphous Sb-zinc tartrate micro-nanospheres powder. Micro-nanosphere diameter is 620nm ( figure 1 ), the atomic percentage of Sb and Zn is 3.32%

Embodiment 2

[0017] 1) Dissolve zinc nitrate and hexamethylenetetramine in water at a molar ratio of 1:1, configure an aqueous solution of zinc nitrate and hexamethylenetetramine with a concentration of 0.15M, and add equimolar Antimony trichloride and potassium sodium tartrate, so that the concentrations of antimony trichloride and potassium sodium tartrate are respectively 0.01M, stir evenly to obtain growth mother liquor;

[0018] 2) Put the growth mother liquid in step 1) into the reaction kettle, keep it warm at 120°C for 1 hour, let the solution stand still, take the precipitate, wash it repeatedly, centrifuge, dry, and obtain amorphous Sb-zinc tartrate micro-nanospheres powder. Micro-nanosphere diameter is 1050nm ( figure 2 ), the atomic percentage of Sb and Zn is 8.29%

Embodiment 3

[0020] 1) Dissolve zinc nitrate and hexamethylenetetramine in water at a molar ratio of 1:1, prepare an aqueous solution of zinc nitrate and hexamethylenetetramine with a concentration of 0.2M, and add antimony potassium tartrate to the prepared solution , so that the concentration of antimony potassium tartrate is 0.02M, stir evenly to obtain the growth mother liquor;

[0021] 2) Put the growth mother solution in step 1) into the reaction kettle, keep it warm at 90°C for 2 hours, let the solution stand, take the precipitate, wash it repeatedly, centrifuge, dry, and obtain amorphous Sb-zinc tartrate micro-nanospheres powder. The diameter of the micro-nanosphere is 1100nm, and the atomic percentage of Sb and Zn is 13.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com