Preparation method of nano iron oxide yellow or nano iron oxide red

A technology of iron oxide yellow and iron -oxide, which is used in the field of preparation of nanomaterials, can solve problems such as heating, insulation, and other effects of production cycle, simple process, and less types of types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

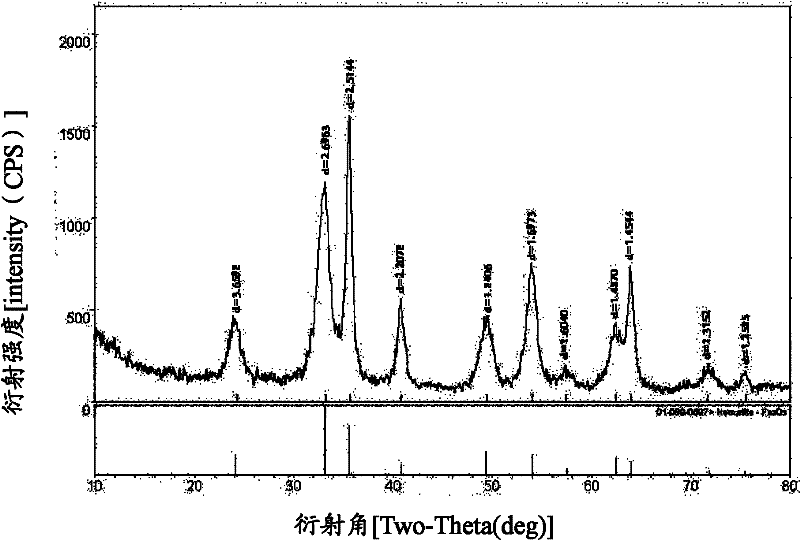

[0032] Weigh FeSO4·7H 2 O analytically pure 14g (0.05mol), made into 1L aqueous solution, add 3.8g tartaric acid and mix well, add 6mol / L ammonia solution dropwise while stirring until the pH value of the reaction system is 4.8, continue to add 20% peroxide dropwise while stirring Hydrogen solution 8mL, continue to react at about 35°C for 90 minutes after addition. After suction filtration and washing, the precipitate was dried in an oven at 100°C to obtain a solid, which was taken out and ground to obtain about 4.6 g of nano iron oxide yellow. The particle size of the nano iron oxide yellow is about 30nm as measured by X-diffraction method and scanning electron microscope method.

[0033] The obtained solid was calcined in a muffle furnace at 900° C. for 1.5 h, taken out, cooled and ground to obtain 4.0 g of nano-iron oxide red. Similarly, the particle size of the nano-iron oxide red is about 75nm as measured by X-diffraction method and scanning electron microscope method. ...

Embodiment 2

[0035] Weigh FeSO 4 ·7H 2O analytical pure 140g (0.5mol), made into 1L aqueous solution, add 48g of citric acid, mix well, add dropwise an aqueous solution of sodium hydroxide with a mass fraction of 10% while stirring until the pH value of the system is 3.8, continue to add dropwise while stirring Add 250ml of sodium hypochlorite aqueous solution with a mass fraction of 20%, and continue to react at room temperature (25° C.) for 2 hours after the addition. After suction filtering and washing the precipitate, place it at 30° C. for 1 hour to dry under vacuum to obtain a solid, which is taken out and ground to obtain about 48 g of nano-iron oxide yellow. The particle size of the nano iron oxide yellow is about 35nm as measured by X-diffraction method and scanning electron microscope method.

[0036] The solid obtained above was calcined in a muffle furnace at 800°C for 1 h, taken out, cooled and ground to obtain about 42 g of nano-iron oxide red. Similarly, the particle size...

Embodiment 3

[0038] Weigh FeSO 4 ·7H 2 O analytical pure 140g (0.5mol) is dubbed into 1L aqueous solution, add 13mL ethylene glycol and mix evenly, dropwise add the sodium hydroxide solution that the mass fraction is 10% while stirring, until the pH value of the reaction system is 4.3, continue to add dropwise while stirring Add 300 mL of sodium persulfate solution with a mass fraction of 30%, and continue to react for about 100 minutes at about 30° C. to form a precipitate. After suction filtration and washing, the precipitate was vacuum-dried at 35°C for 1 hour to obtain a solid, which was taken out and ground to obtain about 44 g of nano-iron oxide yellow. The particle size of the nano iron oxide yellow is about 40nm as measured by X-diffraction method and scanning electron microscope method.

[0039] The obtained solid was calcined in a muffle furnace at 700° C. for 2 h, taken out, cooled, and ground to obtain 40 g of nano-iron oxide red. Similarly, the particle size of the nano-iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com