Bunched electrode high-speed discharge processing method

A cluster electrode and discharge machining technology, which is applied in the field of cluster electrode high-speed discharge machining, can solve problems such as limitations of processing methods, achieve reliable processing performance, realize processing, and process a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

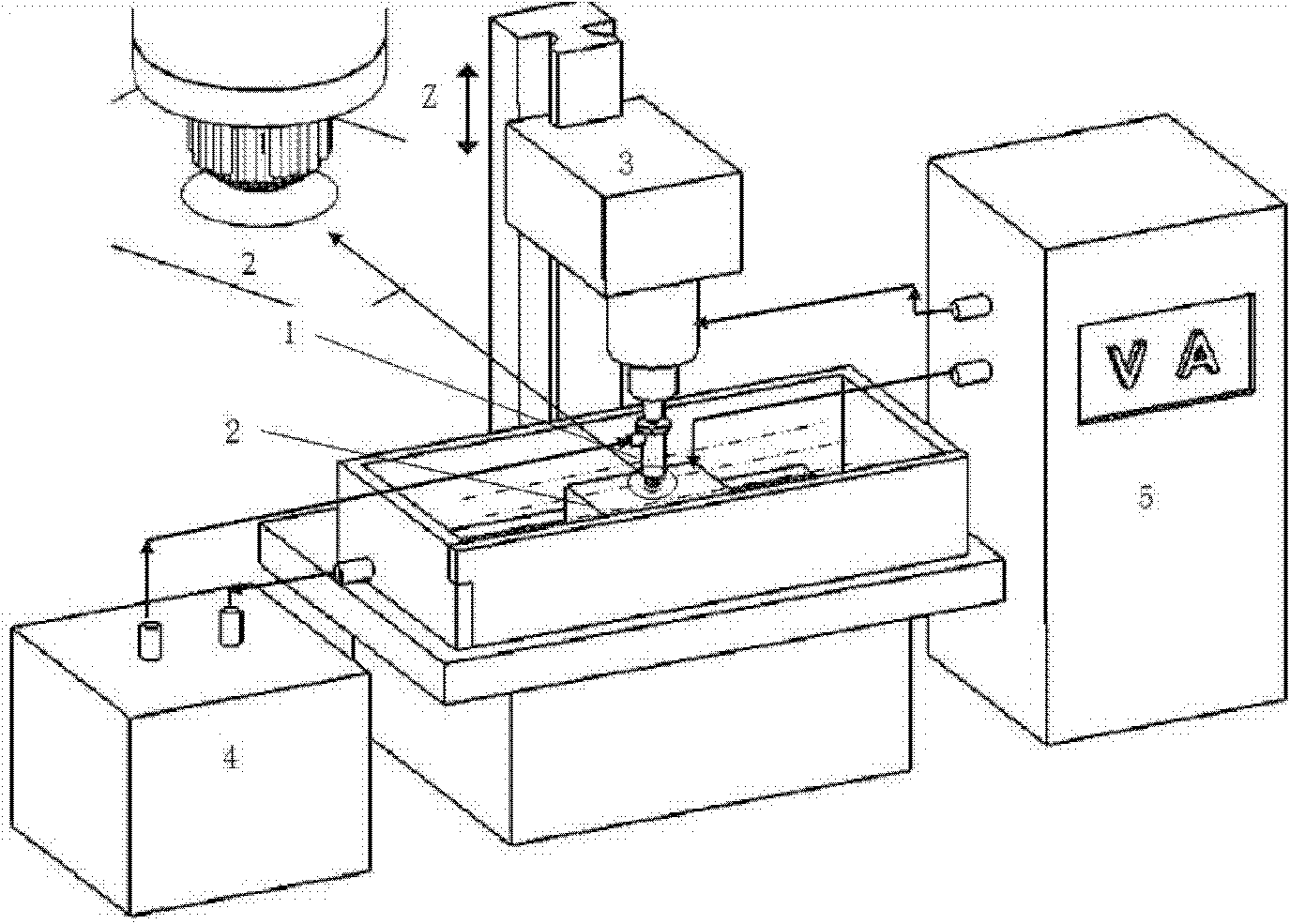

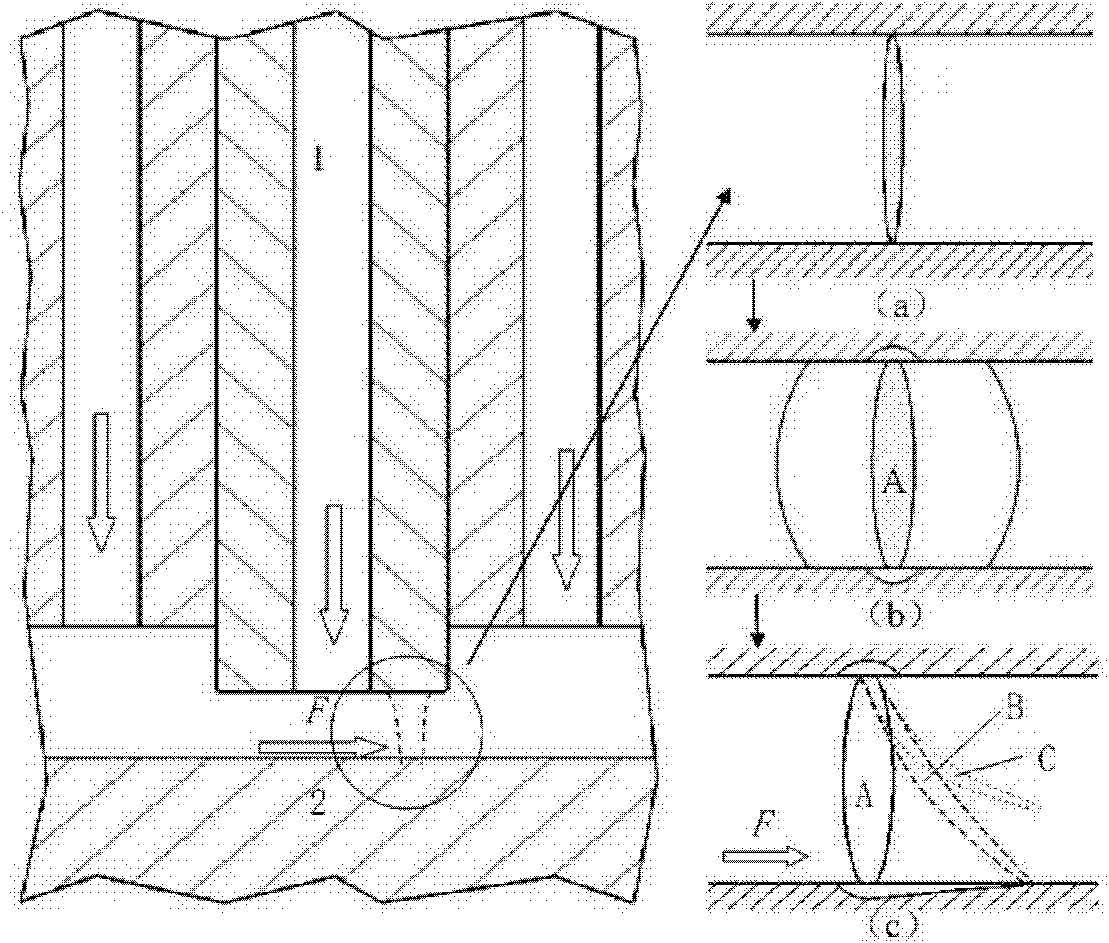

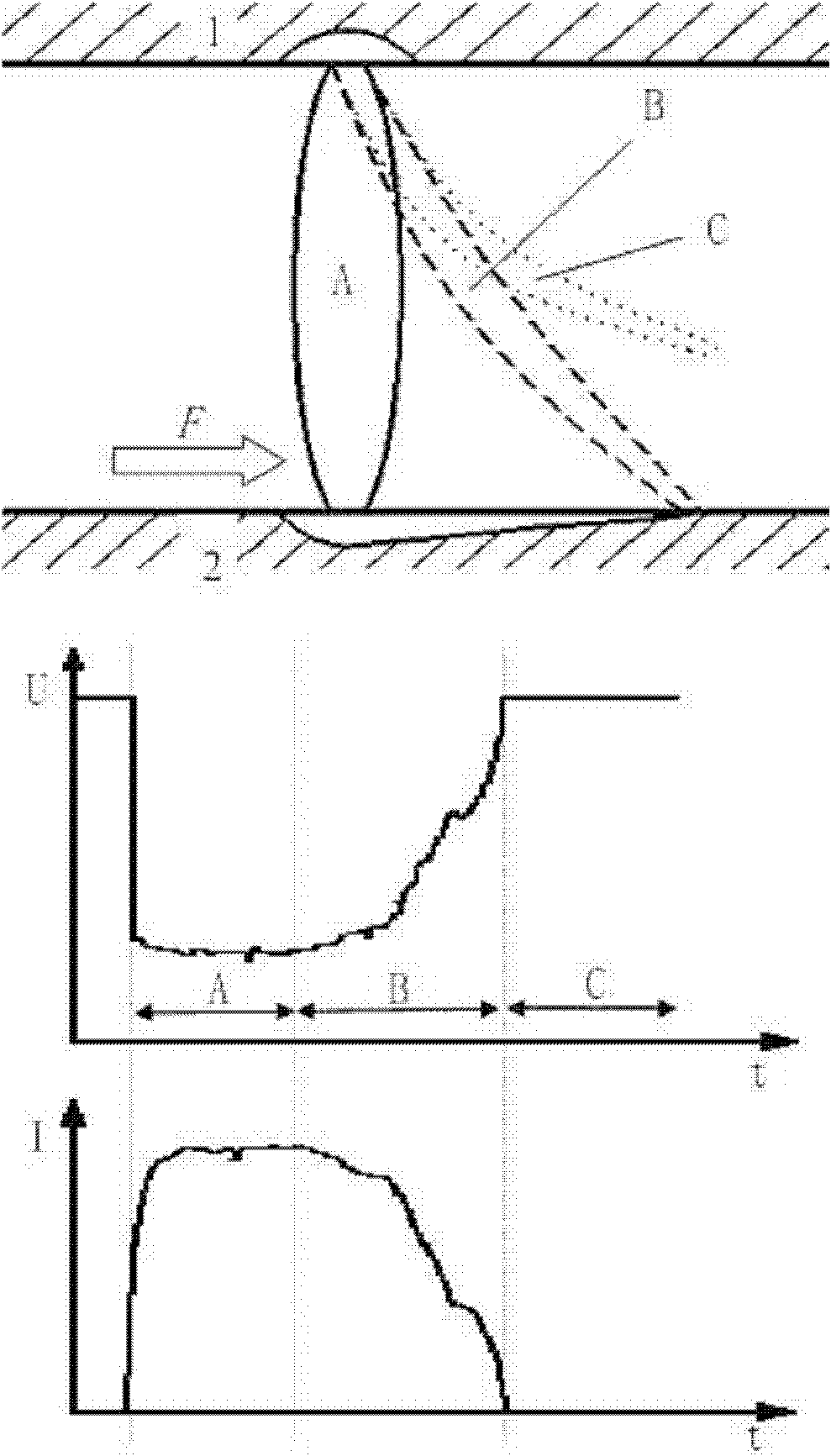

[0029] Using the machine tool 3 with only a single spindle automatic servo feed and retract function, the proper arc discharge gap between the cluster electrode 1 and the workpiece 2 to be processed is maintained through the feed of the spindle. The area of the end surface of the cluster electrode 1 is 500mm 2, the material is graphite, the material of workpiece 2 to be processed is titanium alloy (model TC4), the short arc processing is carried out by using the power parameters of peak voltage 50V, peak current 635A, pulse width 2000μs and pulse interval 200μs, and the water-based working fluid is cutting emulsification The working hydraulic pressure provided by the flushing system is 1.5MPa and the flow rate is 25L / min. Under these processing conditions, the material removal rate of titanium alloy TC4 that can be obtained through simple spindle sinking processing is as high as 6844mm 3 / min, this processing speed is much higher than the maximum material removal rate that c...

Embodiment 2

[0031] Change the workpiece material to fully verify the universal applicability of cluster electrode high-speed electric discharge machining to different materials. The workpiece material is selected as superalloy (GH4169), and the other processing conditions in Example 1 are kept unchanged. The material removal rate of superalloy GH4169 is as high as 6350mm 3 / min.

Embodiment 3

[0033] Select workpiece material to be carbon steel (S45C), keep other processing conditions constant in embodiment 1, the material removal rate of carbon steel S45C is up to 4320mm 3 / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com