Method for preparing submicron hammer ball superfine nickel powder

A sub-micron chain ball-shaped technology, which is applied in the field of preparation of sub-micron chain ball-shaped ultrafine nickel powder, can solve the problems of high carbon content, easy to pollute the environment, and high toxicity, and achieve the effect of low carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

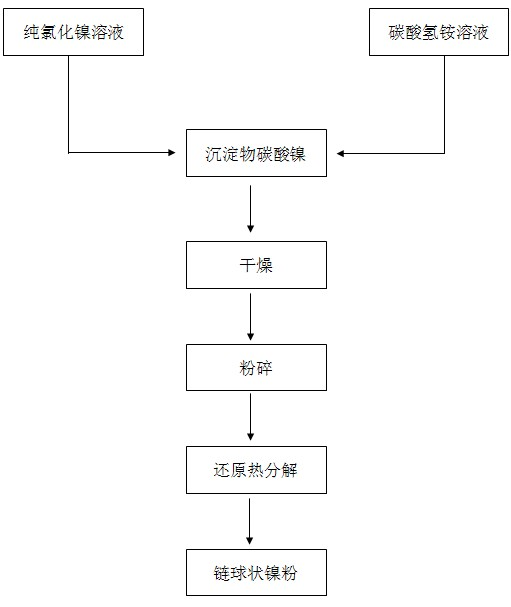

[0020] A preparation method of submicron chain-shaped ultrafine nickel powder, in weight percentage, comprising the following steps: 1, preparing nickel chloride solution: 2, preparing nickel carbonate solid: 3, drying; 4, pulverizing: 5, Reduction thermal decomposition.

[0021] 1. Preparation of nickel chloride solution: by figure 1 Known, the process flow diagram of the production of nickel chloride solution of the chain-shaped ultrafine nickel powder of the present invention.

[0022] 1) Pretreatment of nickel raw materials; adding sulfuric acid solution with a concentration of (2-5%) to nickel-containing raw materials to adjust the pH value to 0.5-1. Nickel raw materials can be ore, alloy steel or other nickel-containing solids. React at a temperature of 90°C for 1 hour to dissolve to obtain nickel sulfate solution, the chemical composition of which is shown in Table 1:

[0023] Table 1 Chemical composition of nickel sulfate solution

[0024] Elemental composi...

Embodiment 1

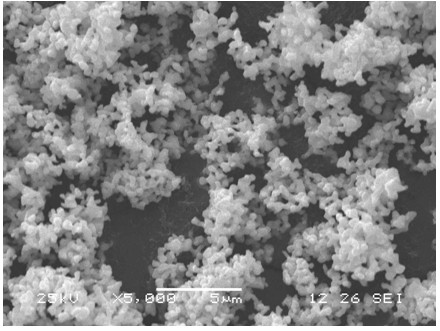

[0047] Put the pure nickel chloride solution in Table 3 and the precipitant solution ammonium bicarbonate into the same reaction kettle, control a certain flow rate, the reaction temperature is 55°C, the pH is adjusted to 6.3, and the precipitate is filtered and washed for 2 hours, and the drying temperature is 120°C. After 12 hours, put the dried nickel carbonate into a box, put it into a PID-regulated electric furnace, control the temperature at 350°C, and carry out reduction thermal decomposition under the control of hydrogen and nitrogen atmospheres to obtain submicron chain-shaped ultrafine nickel powder .

Embodiment 2

[0049] Put the pure nickel chloride solution and precipitant solution ammonium bicarbonate in Table 3 into the same reaction kettle, control a certain flow rate, the reaction temperature is 60°C, the pH is adjusted to 6.5, and the precipitation is filtered and washed for 2 hours, the drying temperature is 120°C, and the time is 10 After hours, put the dried nickel carbonate into a box, put it into a PID-regulated electric furnace, control the temperature at 400°C, and carry out reductive thermal decomposition under the control of hydrogen and nitrogen atmospheres to obtain submicron chain-shaped ultrafine nickel powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com